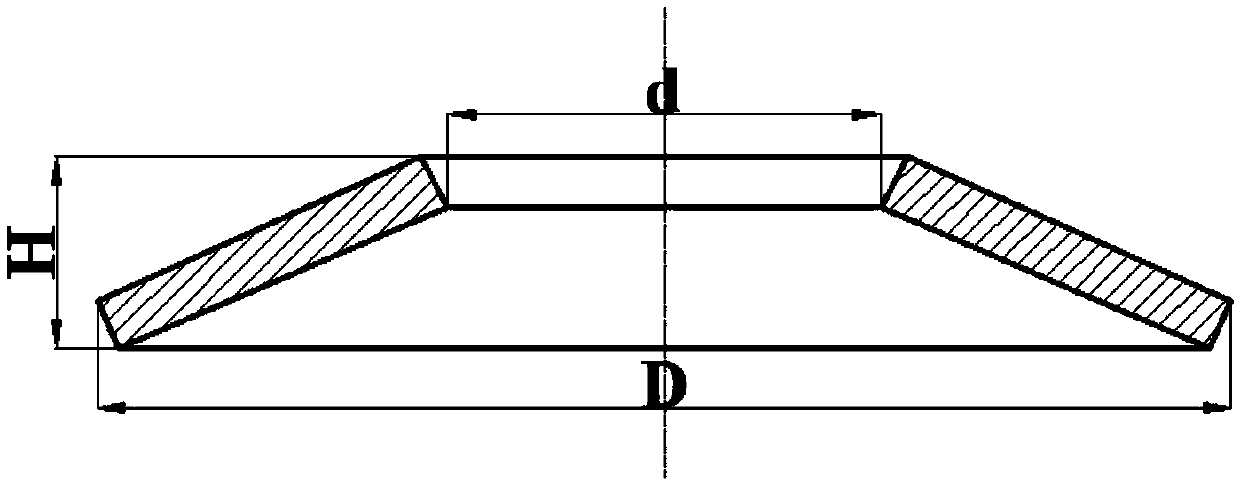

Butterfly spring three-dimensional size automatic measuring system and measuring method based on machine vision

A butterfly spring, automatic measurement technology, applied in measuring devices, instruments, optical devices, etc., can solve the problems of complex industrial camera installation and detection devices, inability to apply three-dimensional measurement of butterfly springs, and easy fatigue of the naked eye, etc. The effect of detection efficiency and accuracy, flexible measurement and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

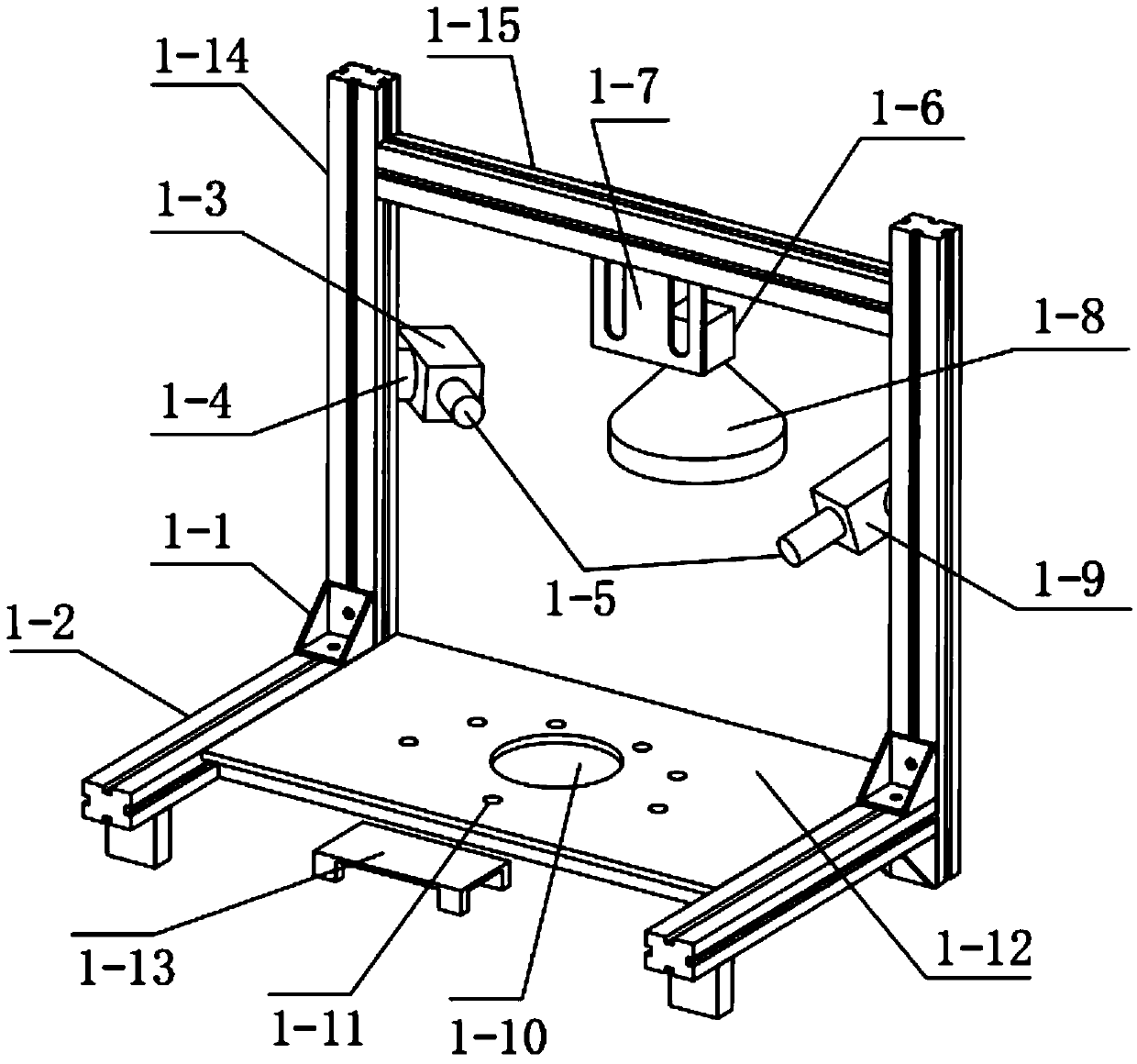

[0042] A machine vision-based automatic three-dimensional size measurement system for Belleville springs, such as figure 1 As shown, it includes a hardware part, the hardware part includes a detection device, and the detection device includes a base 1-2, and the upper side of the base 1-2 is symmetrically fixed with two vertical poles through the corner connector 1-1 1-14, a horizontal bar 1-15 is fixedly installed between the two vertical poles 1-14 close to their upper ends, and the middle parts of the two vertical poles 1-14 are respectively fixedly installed with a camera through the connecting seat 1-4 CL1-9 and camera CR1-3, the middle bottom of the crossbar 1-15 is fixedly installed with a camera CT1-6 through the fitting seat 1-7, and both the camera CL1-9 and the camera CR1-3 are installed There is an ordinary optical lens 1-5, a telecentric optical lens 1-8 is installed on the camera CT1-6, a backlight source 1-13 is installed on the bottom of the base 1-2, and the u...

Embodiment 2

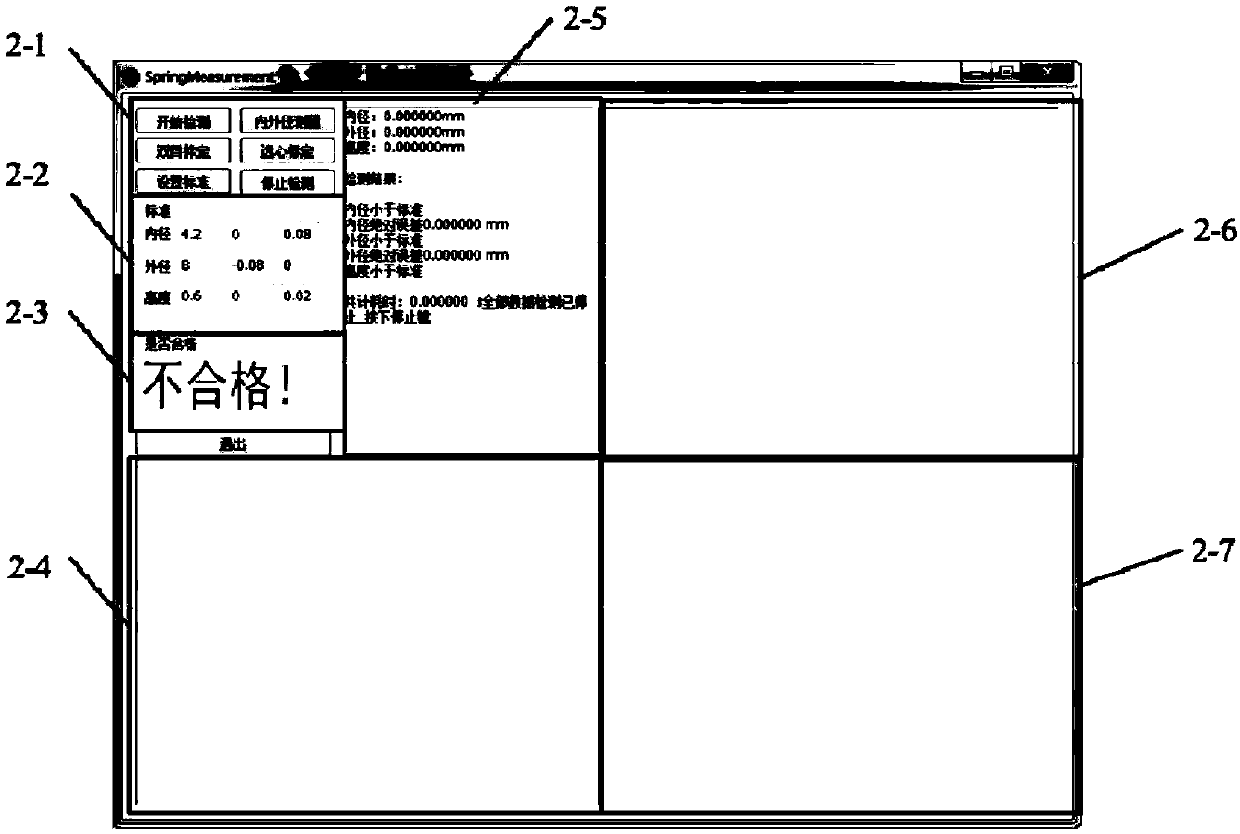

[0057] According to the three-dimensional automatic measurement system of butterfly spring based on machine vision built according to the embodiment 1, the software of the three-dimensional automatic measurement system of butterfly spring based on machine vision is run on the PC, and the camera CL1- 9. CR1-3, CT1-6, carry out system calibration, the calibration parameters are stored in the PC, place any butterfly spring on the frosted glass to be tested, and select the "Start Test" button in the functional area 2-1 to enter the test process , the measurement results are displayed in the test result display area 2-5 in real time, and the test personnel sort out the qualified butterfly springs by observing the test results or the information in the prompt bar.

Embodiment 3

[0059] According to the machine vision-based automatic three-dimensional dimension measurement method of the Belleville spring of embodiment 2, the method is: the camera works at a certain frame rate, and each frame image collected by the camera CT is compared with the previous frame image, and the grayscale is used The information represents the image attributes of each frame, and the gray information of the front and rear images automatically enters the detection program within a certain threshold range.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com