Docking method for container terminal management system and automatic driving container truck

A container truck and management system technology, which is applied in the field of automatic driving, can solve problems such as high risk and affecting the position accuracy of automatic driving vehicles, and achieve the effect of reducing investment and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific implementation of the present invention will be described in detail below in conjunction with preferred embodiments.

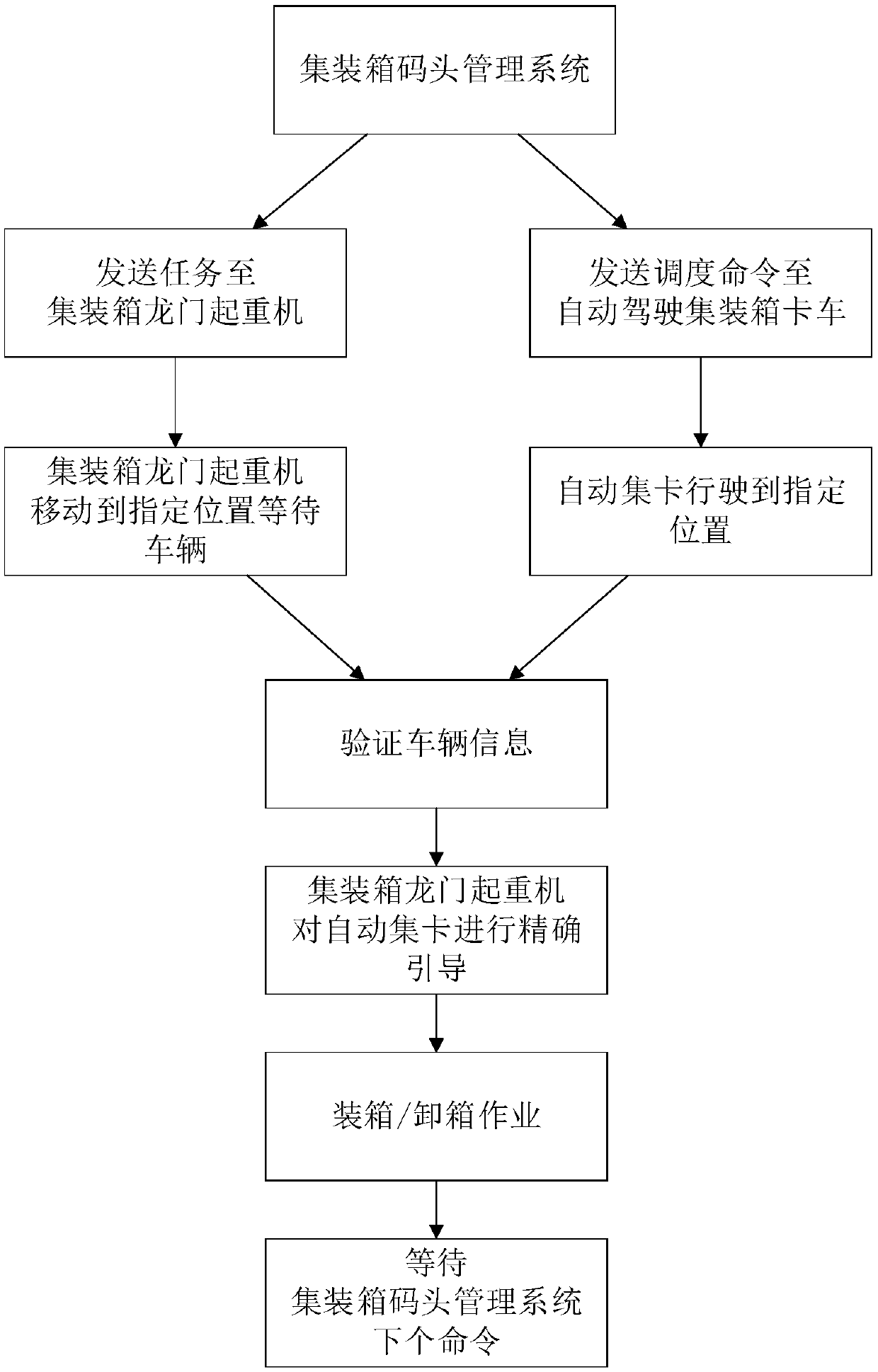

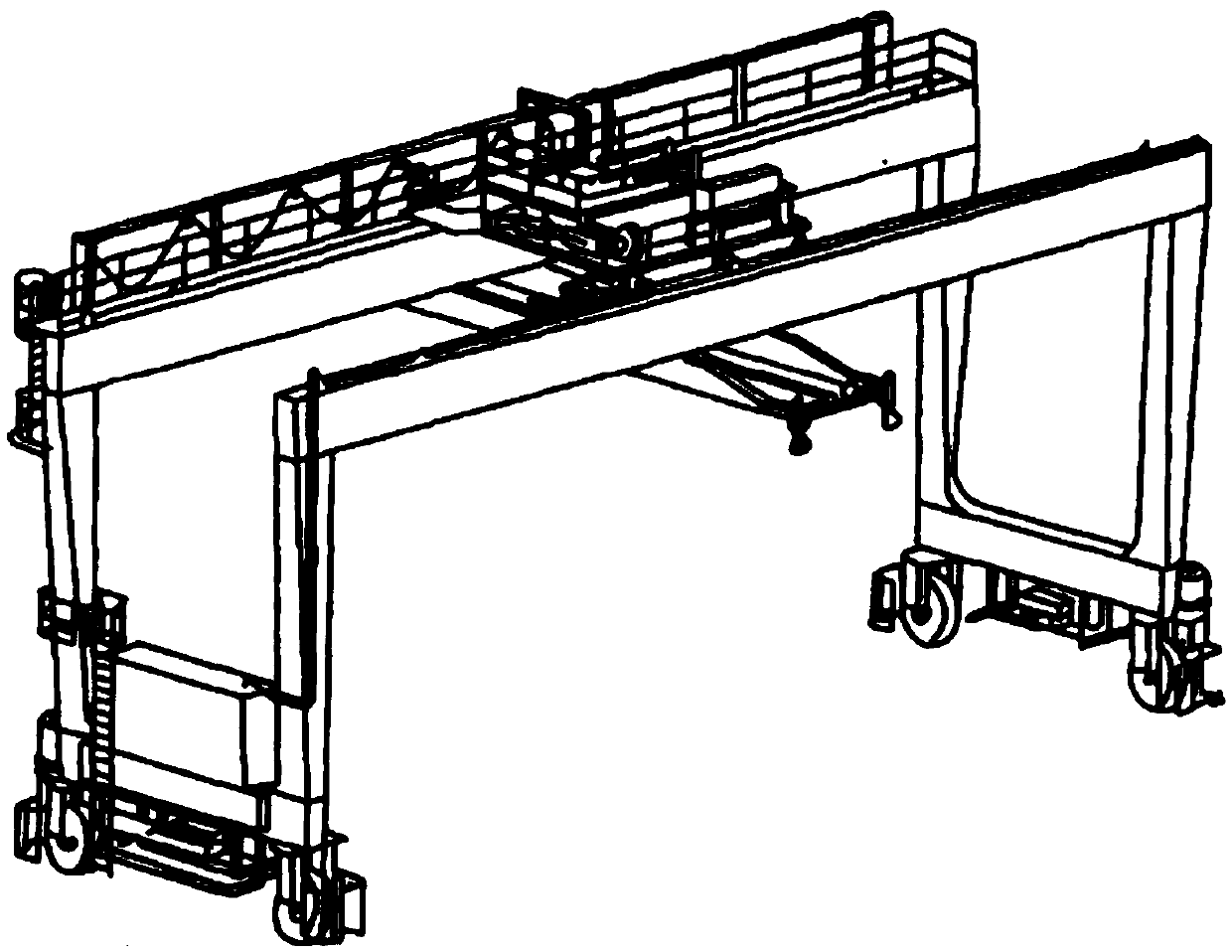

[0034] See the accompanying drawings for details. This embodiment provides a docking method between the container terminal management system and the self-driving container truck. After the network system is set up, the self-driving container truck will be directed to the operating bay through the scheduling command of the container terminal management system to realize The container terminal management system dispatches the first stage of self-driving container trucks; then the container gantry crane provides centimeter-level precise guidance to guide the self-driving container trucks to accurately dock in the operable area of loading / unloading to realize the second stage of docking stage, the specific steps are as follows:

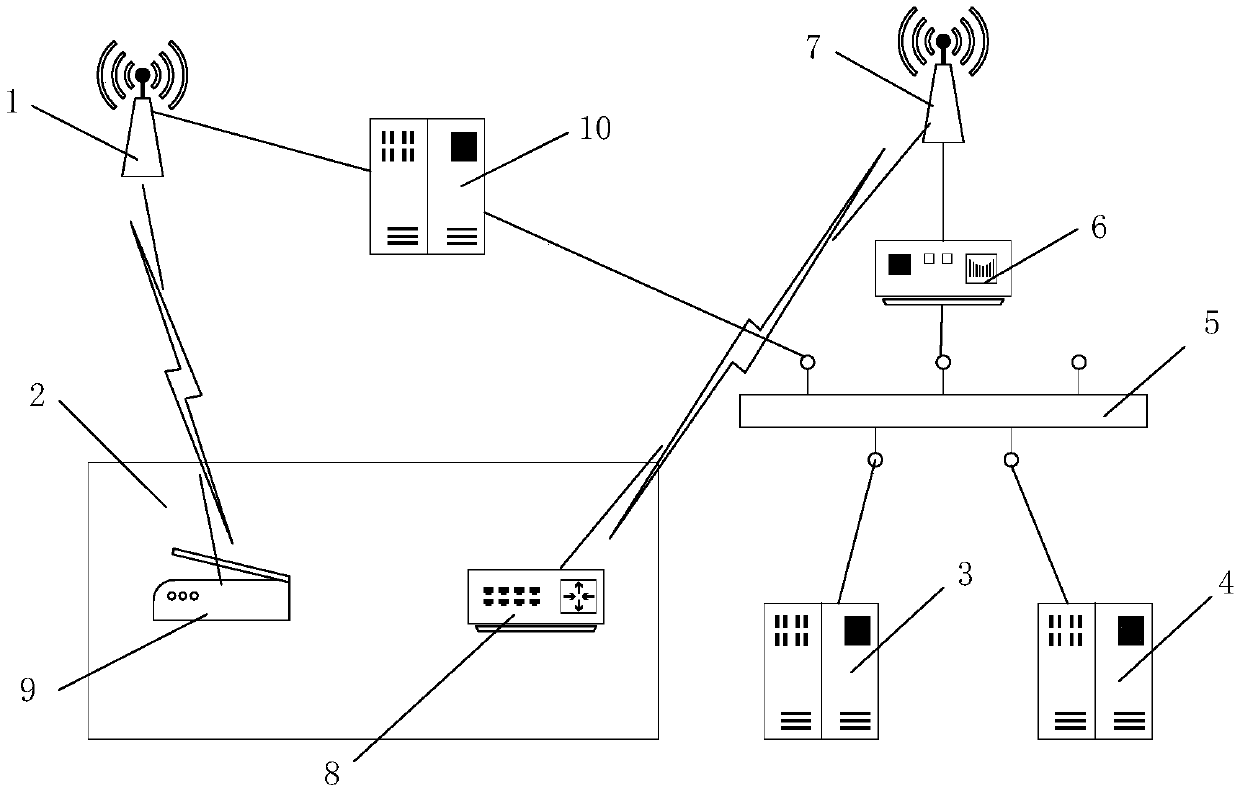

[0035] Such as figure 1 As shown, it is a schematic diagram of the network equipment connection of the present in...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap