Electric power switch equivalent pressure vacuum pumping and inflating device and control method thereof

A technology of power switch and inflatable device, which is applied in the direction of electric switch, pump control, pump device, etc., can solve the problems of low work efficiency, long work cycle, time-consuming and laborious, etc., and achieves convenient operation, reasonable overall structure design, and prevention of internal and external pressure. The effect is too large to damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

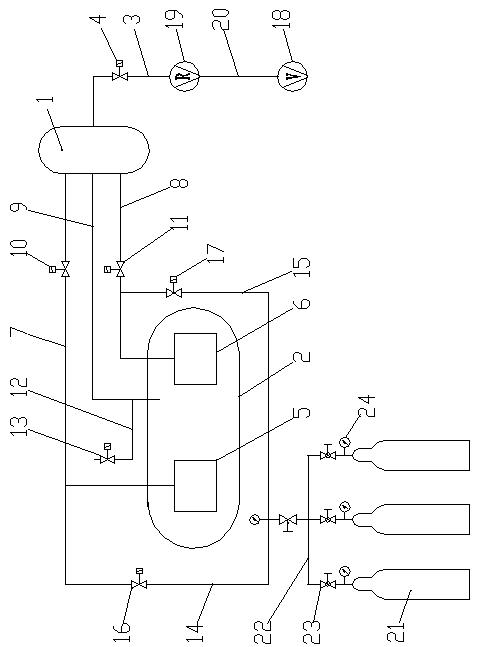

[0023] like figure 1 and figure 2 As shown, the power switch isobaric vacuuming and gas charging device of the present invention includes a vacuum pump group, a buffer 1, a vacuum box 2, a high-pressure nitrogen cylinder group and a PLC controller, and the vacuum pump group is connected with the buffer 1 through a main vacuum tube 3, The main vacuum tube 3 is provided with a first solenoid valve 4, the vacuum box 2 is provided with a first power switch 5 and a second power switch 6, the buffer 1 is connected to the first power switch 5 through the first vacuum tube 7, and the buffer 1 The second vacuum tube 8 is connected to the second power switch 6, the buffer 1 is connected to the vacuum box 2 through the third vacuum tube 9, the first vacuum tube 7 is provided with a second electromagnetic valve 10, and the second vacuum tube 8 is provided with a third electromagnetic valve. valve 11, the third vacuum pipe 9 is connected with an intake pipe 12, and the intake pipe 12 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com