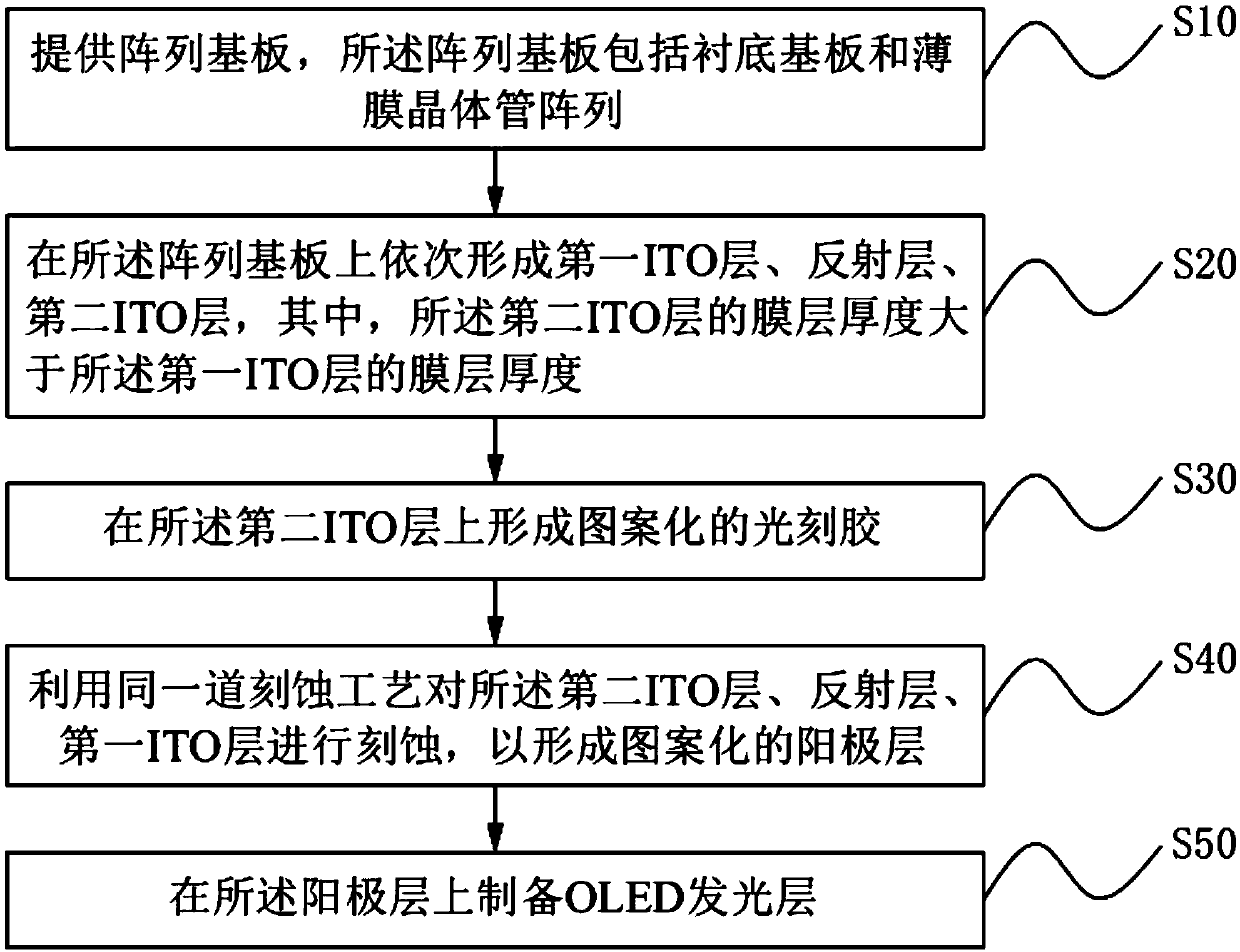

Method for fabricating OLED display panel and OLED display panel

A display panel and manufacturing method technology, applied in semiconductor/solid-state device manufacturing, organic semiconductor devices, electrical components, etc., can solve the problems of lack of photoresist, affecting the performance of display devices, changes in metal surfaces, etc., to ensure stable quality sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

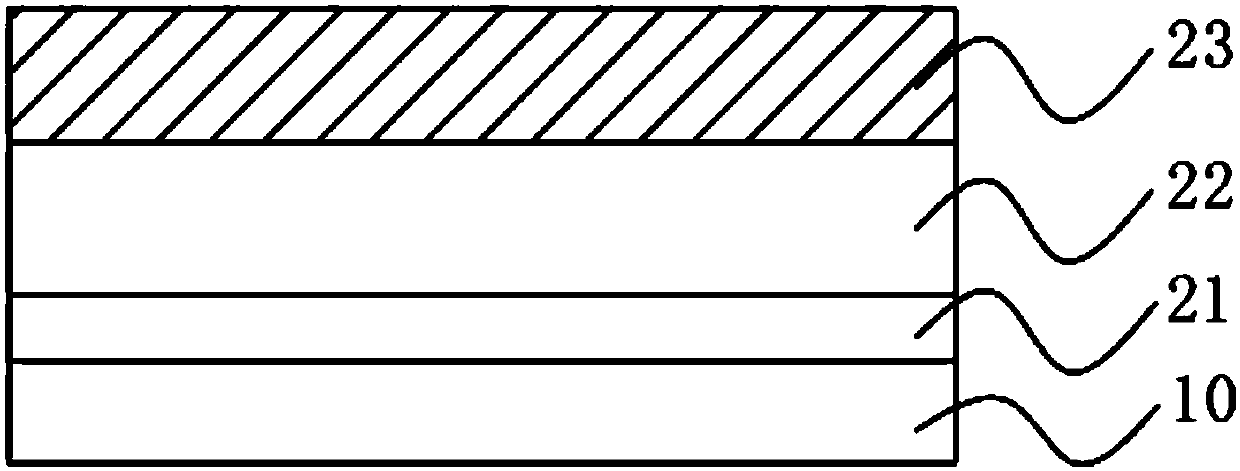

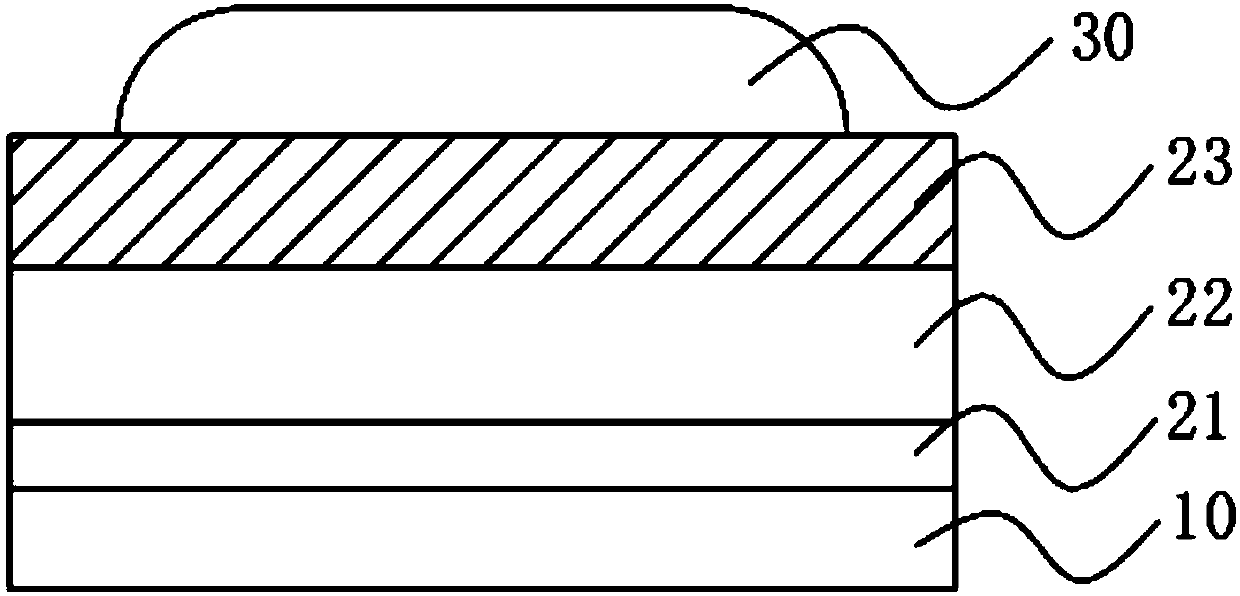

[0032] The description of the following embodiments refers to the attached drawings to illustrate specific embodiments in which the present invention can be implemented. The directional terms mentioned in the present invention, such as [Up], [Down], [Front], [Back], [Left], [Right], [Inner], [Outer], [Side], etc., are for reference only The direction of the additional schema. Therefore, the directional terms used are used to describe and understand the present invention, rather than to limit the present invention. In the figure, units with similar structures are indicated by the same reference numerals.

[0033] The present invention is directed to the existing manufacturing method of the OLED display panel. Since the photoresist may be missing during the etching process when the OLED anode is prepared, the areas where the metal layer does not need to be etched are exposed, resulting in changes in the properties of the metal surface. Furthermore, the technical problem that affe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com