Tobacco granule type tobacco product incombustible in heating and making method thereof

A heat-not-burn and tobacco particle technology, which is applied in the fields of tobacco, processed tobacco, and smoker's supplies, can solve the problems of complicated manufacturing process, reburned paper smell, and inconvenient operation, and achieves simple preparation process, good heat resistance, and sealing The effect of blocking firm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

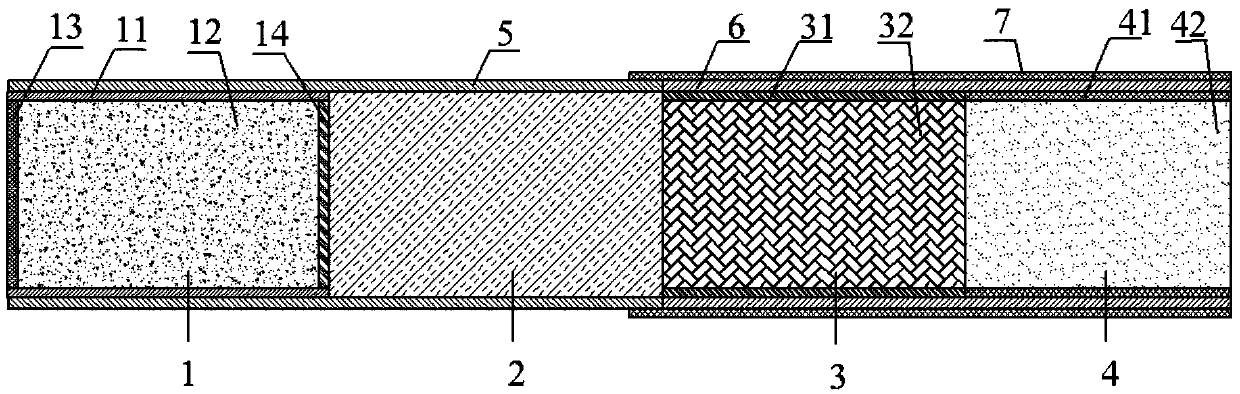

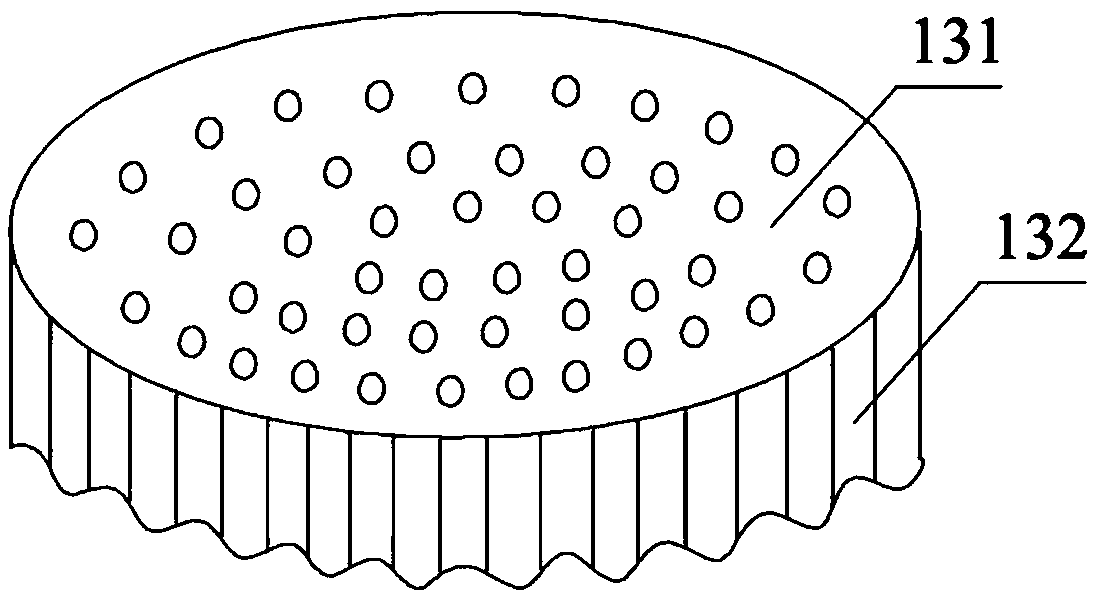

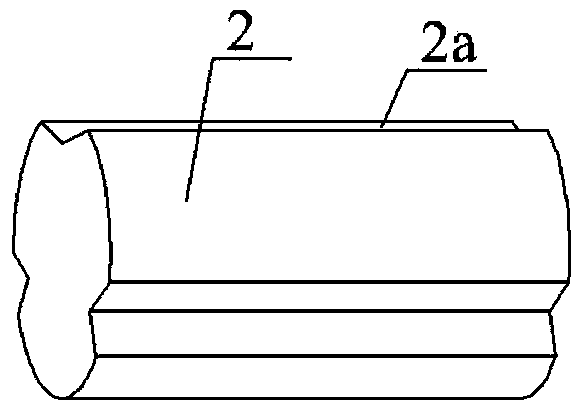

[0044] Such as figure 1 As shown, a tobacco particle type heat-not-burn tobacco product includes a tobacco particle segment 1 and a filter tip segment. Tobacco particle segment 1 is fixed with a front end sealing structure 13 and a tail end sealing structure 14 at the front end and tail end of the paper empty tube 11 respectively, and tobacco particles are filled between the front end sealing structure 13 and the tail end sealing structure 14 12; the tail end blocking structure 14 is adjacent to the filter section. The filter section includes a first cooling section 2, a second cooling section 3 and a filter sect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com