Composite nanometer structure copper catalyst for preparing furfuralcohol through furfural hydrogenation and preparation method thereof

A technology of composite nanostructures and copper catalysts, which is applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as harsh operating conditions, high cost, and complicated operations, and achieve easy modification of the inner surface and skeleton The effect of stable structure and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

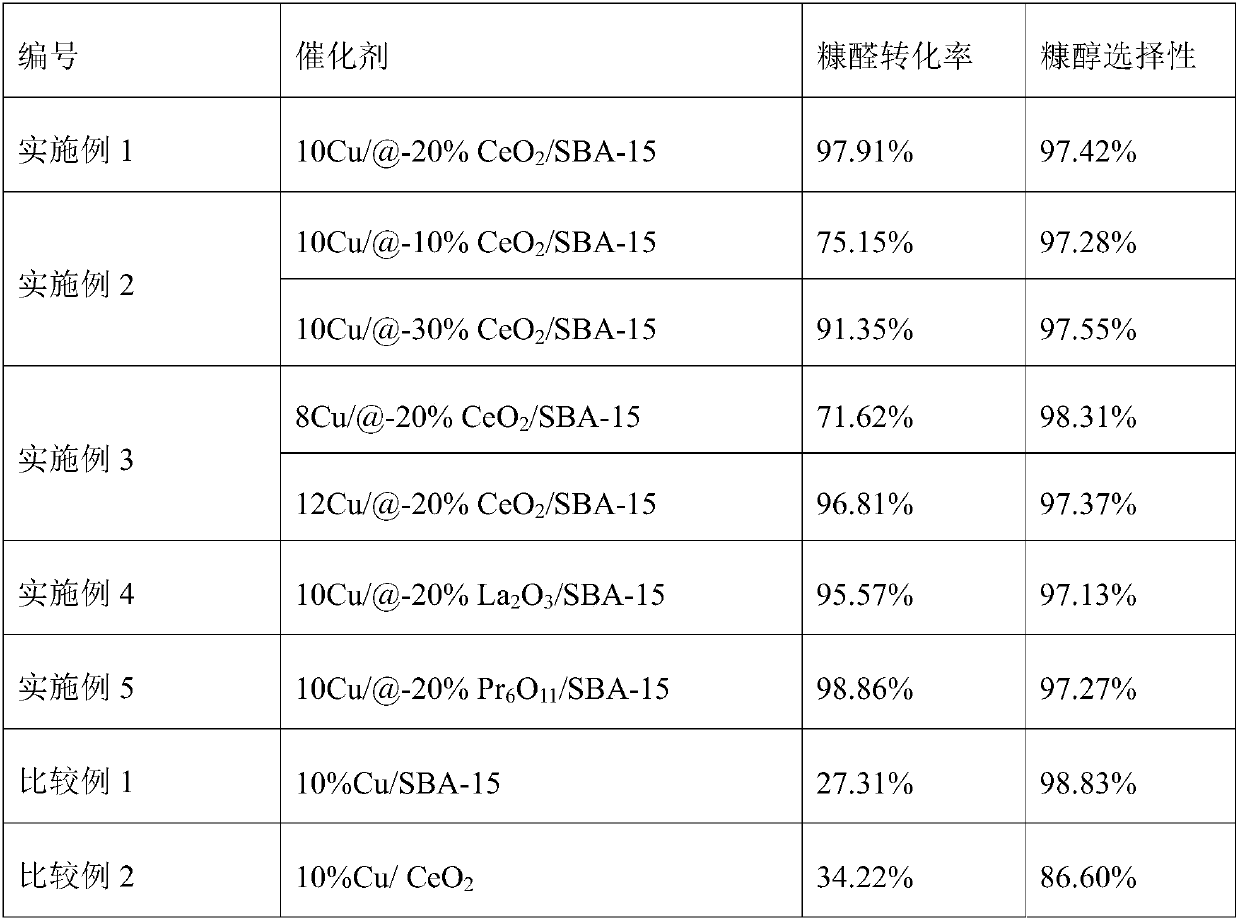

Examples

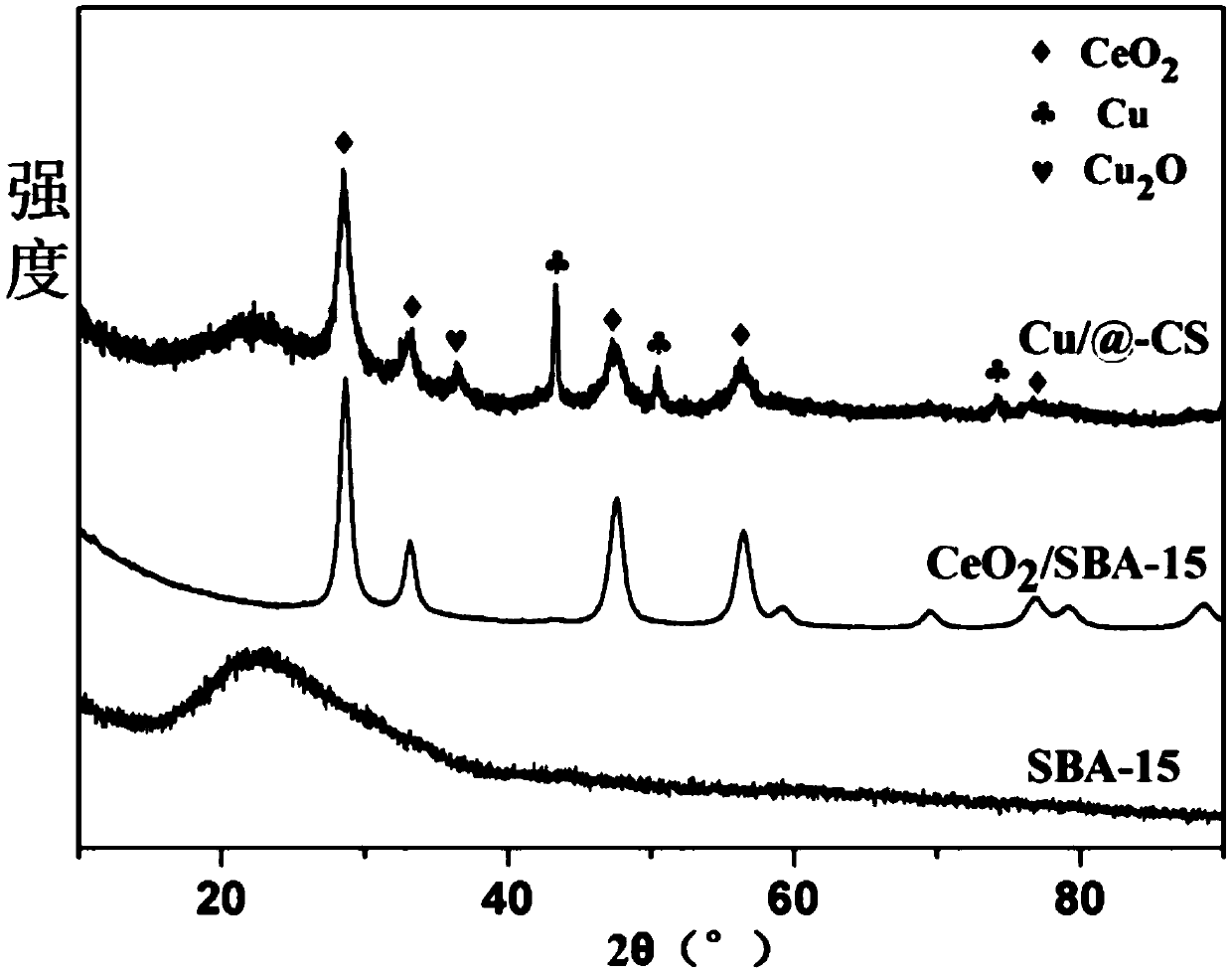

Embodiment 1

[0031] 1. 20% CeO 2 / SBA-15 composite carrier preparation, specifically: prepare a solution containing 26ml deionized water and 0.378g cerium nitrate, add 0.6g SBA-15 molecular sieve, and stir at 80°C for 4h; move the mixed solution into an ultrasonic vibration After 20 minutes, add 1.5-2mol / L ammonia solution at a rate of 1-4.5ml / min to adjust the pH value to 7.5-8.5; then continue to stir in a water bath at 80°C, and let it stand for 12h after 4-6h; The solution was washed with deionized water, filtered, and dried in a drying oven for 12 to 15 hours, and then the product was calcined at 500°C for 2 hours to obtain 20% CeO 2 / SBA-15 composite carrier.

[0032] 2. 10Cu / @-20%CeO 2 / SBA-15 catalyst preparation, specifically: get 0.482g polyvinylpyrrolidone K-30 and dissolve in 32ml ethylene glycol, add 0.5g of 20% CeO 2 / SBA-15 composite carrier mixed evenly; take 0.212g copper nitrate trihydrate and dissolve it in 12ml water, add it to the above mixed solution in the ultraso...

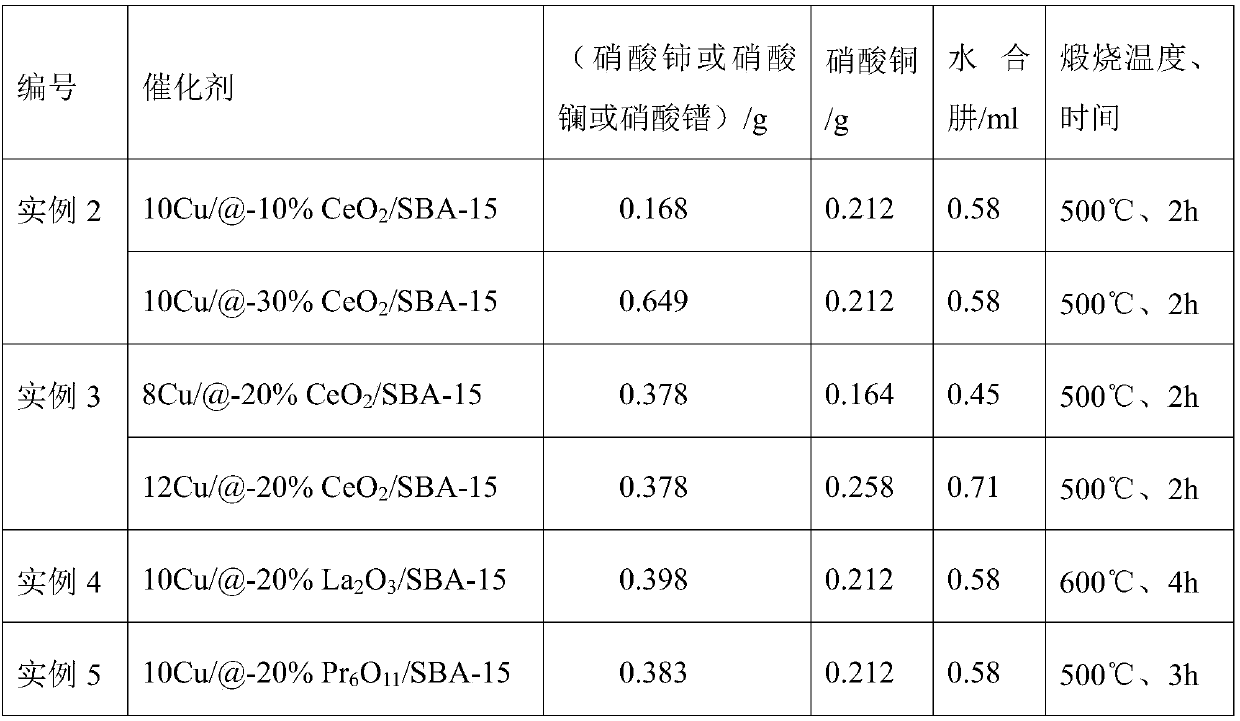

Embodiment 2

[0034] Except that the mass content of CeO2 in the composite carrier was replaced with that shown in Table 1, the rest of the steps and conditions were the same as in Example 1.

Embodiment 3

[0036] Except for 10Cu / @-20%CeO 2In the / SBA-15 catalyst, the mass content of Cu was replaced as shown in Table 1, and all the other steps and conditions were the same as in Example 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap