Forging mold

A technology for molds and storage boxes, which is used in manufacturing tools, forging/pressing/hammer devices, forging/pressing/hammering machines, etc., can solve the trouble of taking out the workpiece, cannot effectively and accurately adjust the injection height of the workpiece, and the workpiece sticks together. and other problems to achieve the effect of improving the molding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0024] In order to make it easy to understand the technical means, creation features, achieved goals and effects of the present invention, the present invention will be further described below with reference to the specific embodiments.

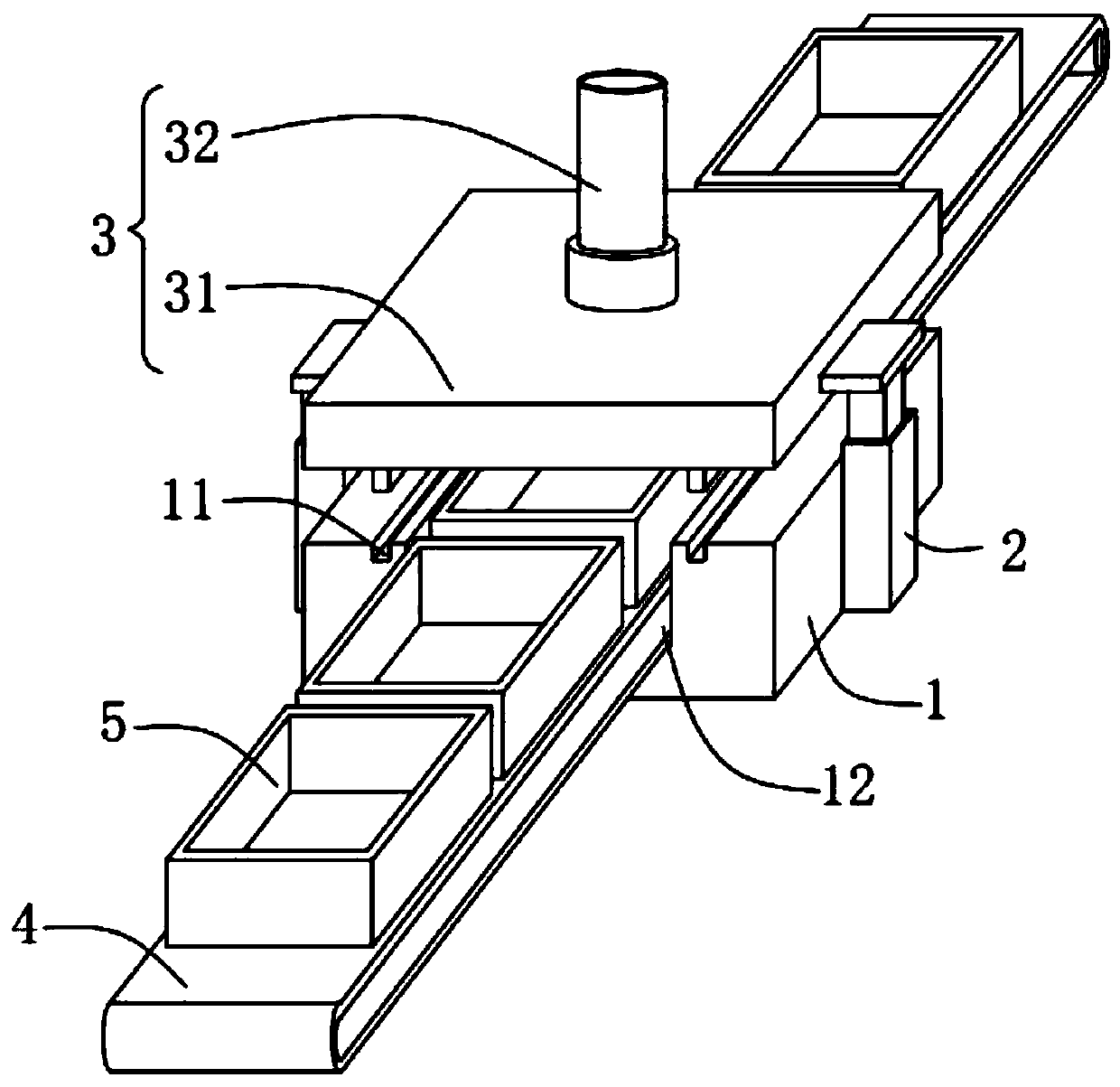

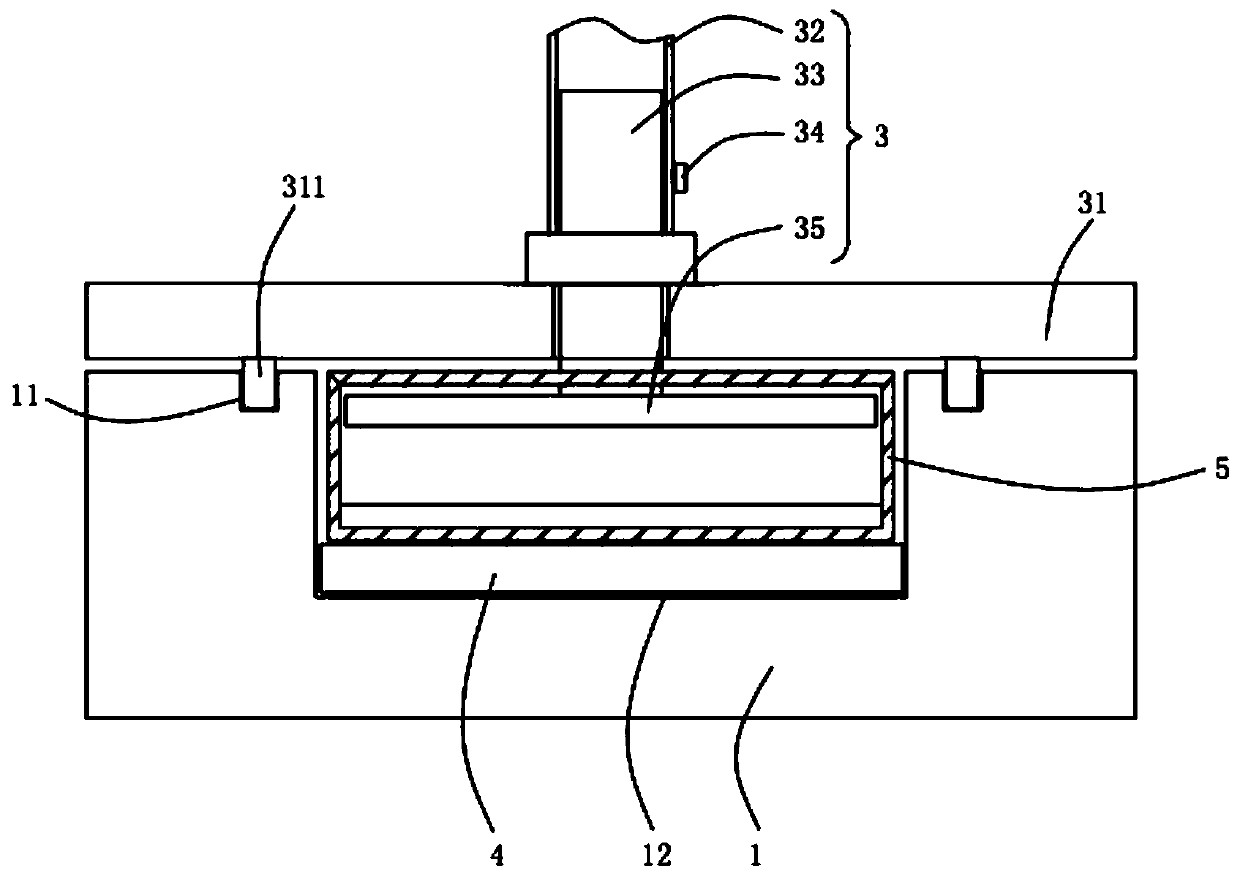

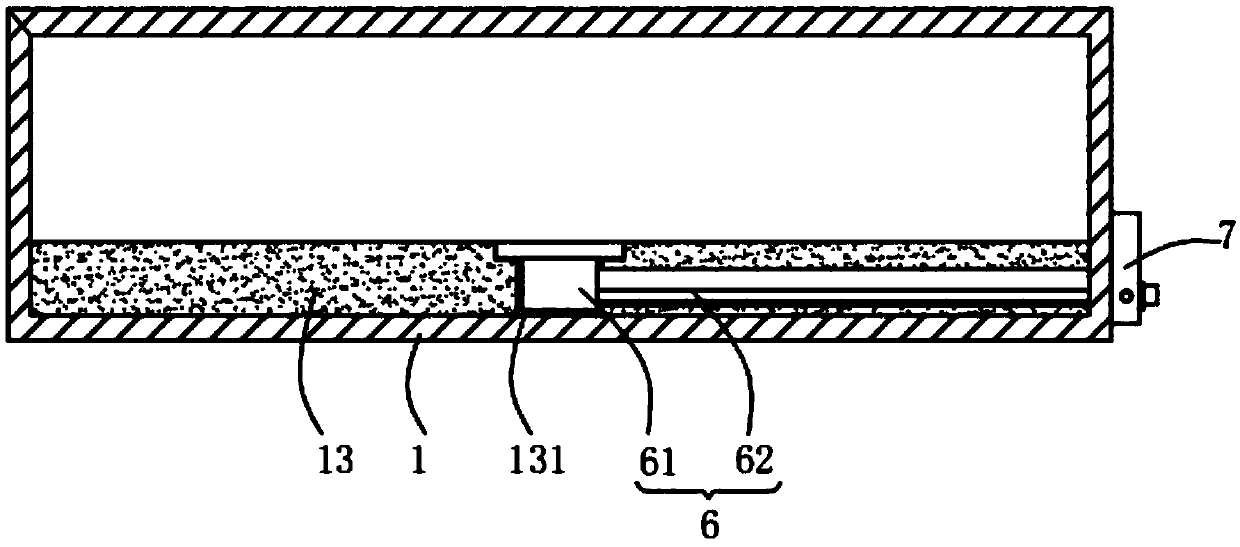

[0025] like Figure 1-Figure 5 As shown, a forging die according to the present invention includes a base 1, a pneumatic rod 2, a feeding mechanism 3, a conveyor belt 4, a storage box 5, an ejection mechanism 6 and a moving mechanism 7; the interior of the base 1 The conveyor belt 4 runs through, the surface of the conveyor belt 4 is placed in the storage box 5, and the storage box 5 is used to form the workpiece; the two side walls of the base 1 are connected to the The feeding mechanism 3; the top of the base 1 is equipped with the feeding mechanism 3, and the feeding mechanism 3 is used to pour the molten material into the storage box 5; the inner bottom layer of the storage box 5 is provided with the The ejecting mechanism 6 is connected...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap