Automatic environment-friendly stainless steel kettle body polisher

A stainless steel and polishing machine technology, which is applied to surface polishing machine tools, grinding/polishing equipment, grinding racks, etc., can solve the problems of high labor intensity, poor quality, and low efficiency, and achieve the purpose of improving the life of the pot body and reducing investment Small, high surface finish effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

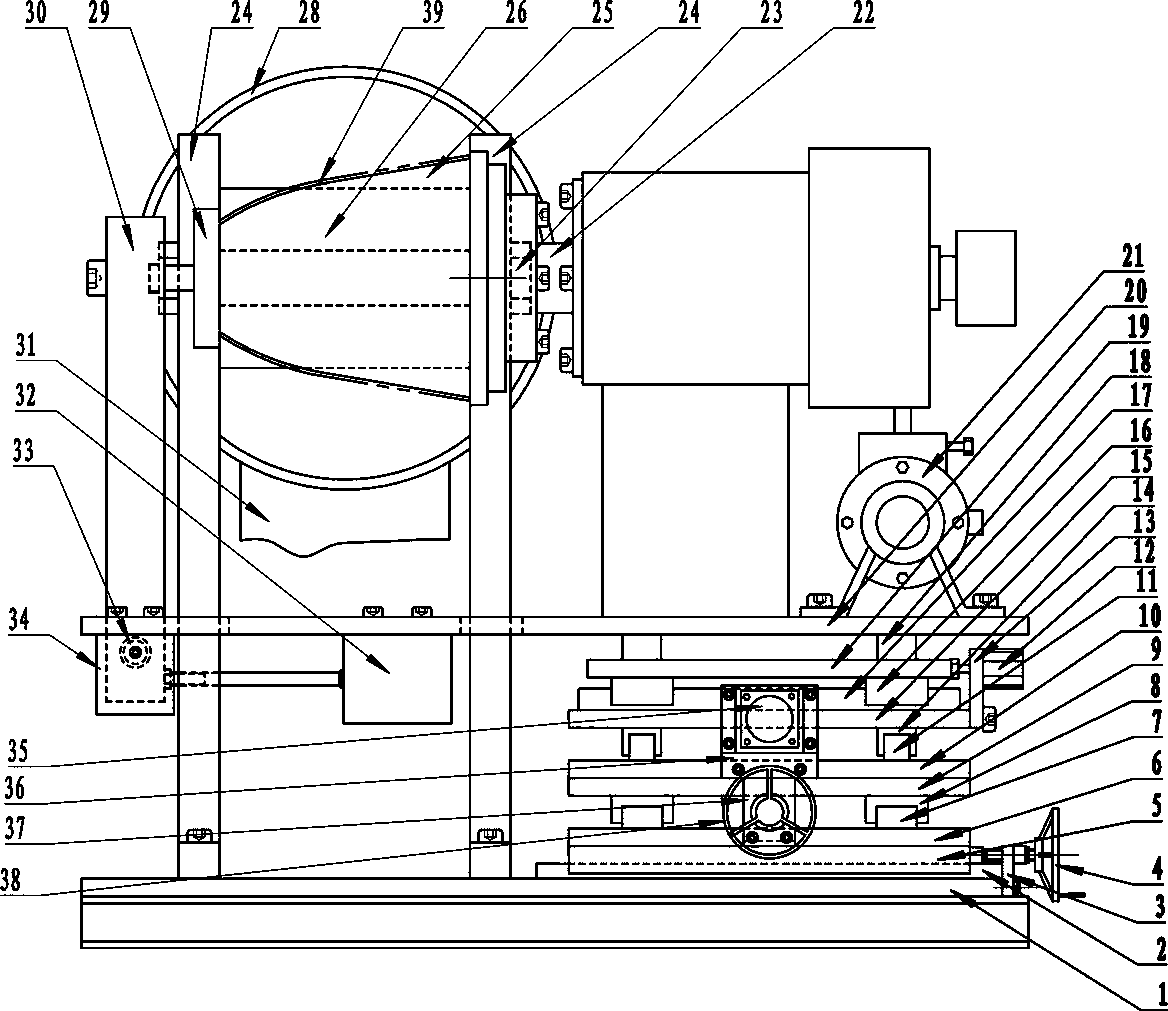

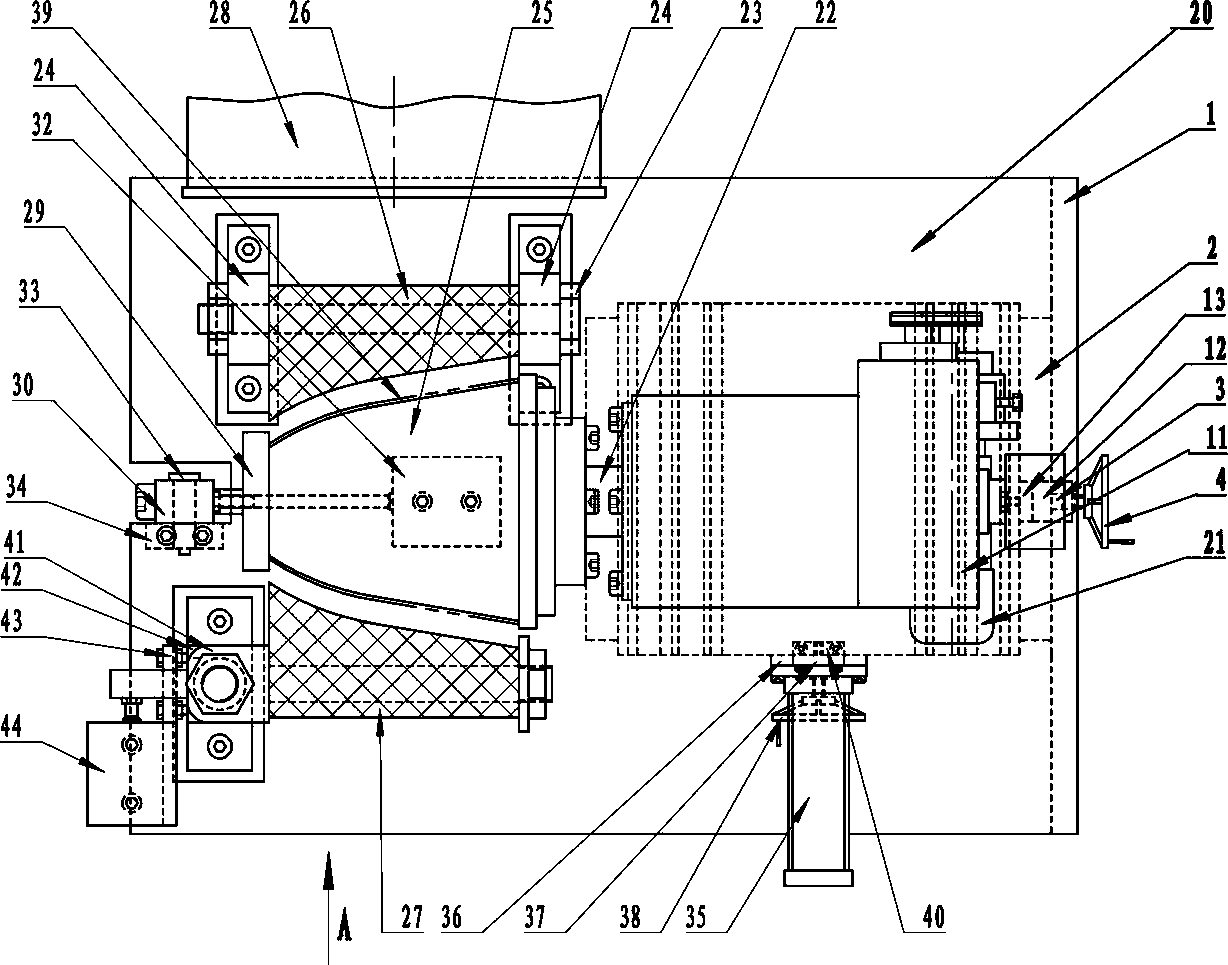

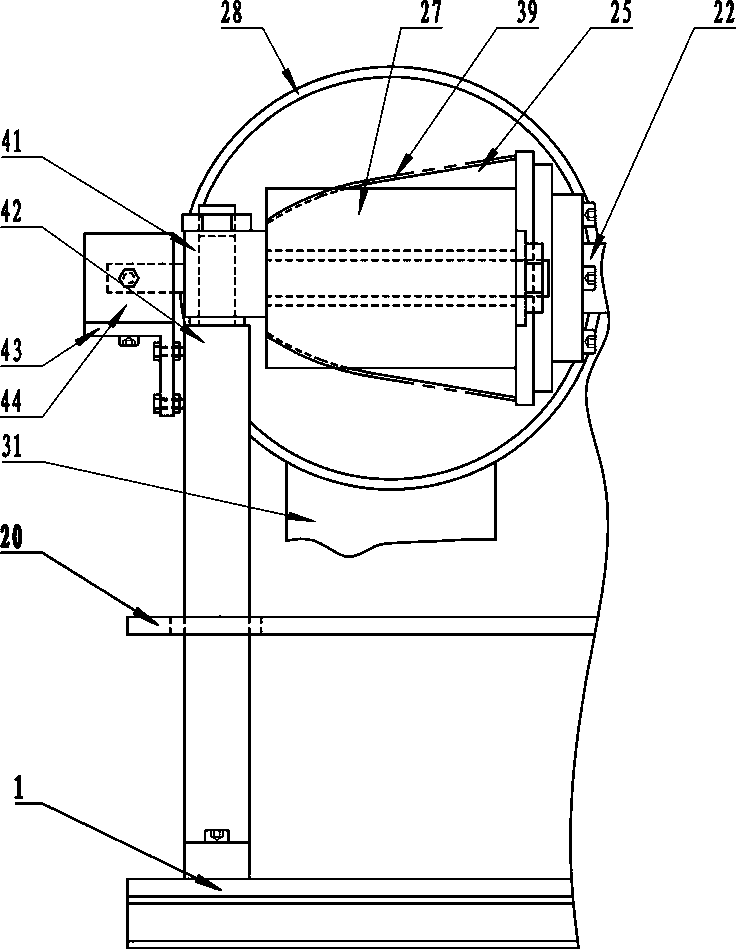

[0019] Combine below figure 1 , figure 2 and image 3 The present invention is further described.

[0020] The automatic environmental protection stainless steel pot body polishing machine has a base 1 and a workbench 20 is installed through the support strip 18 on the upper right side of the base, and a rotary drive mechanism 21 is arranged on the right side of the workbench 20. Its characteristics are: the workbench 20 top rotary drive mechanisms 21 drive axle boxes are provided with drive shaft 22, and this shaft is equipped with pot body support die head 25 by axle head flange, is provided with pot body grinding and polishing device at the pot body support die head 25 rear side, in A bracket A24 passing through the slotted hole of the workbench is installed on the left rear side of the base 1, and the polished and formed cloth piece 26 is installed on the upper part of the bracket A24 through the mandrel 23; , a bracket C42 passing through the slotted hole of the workb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com