Magnetic drive micro-motion amplifying snake robot

A technology of robot snakes and magnetic drives, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as high cost and technical requirements, complex structure, etc., achieve low manufacturing technical requirements, reduce space volume and weight, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

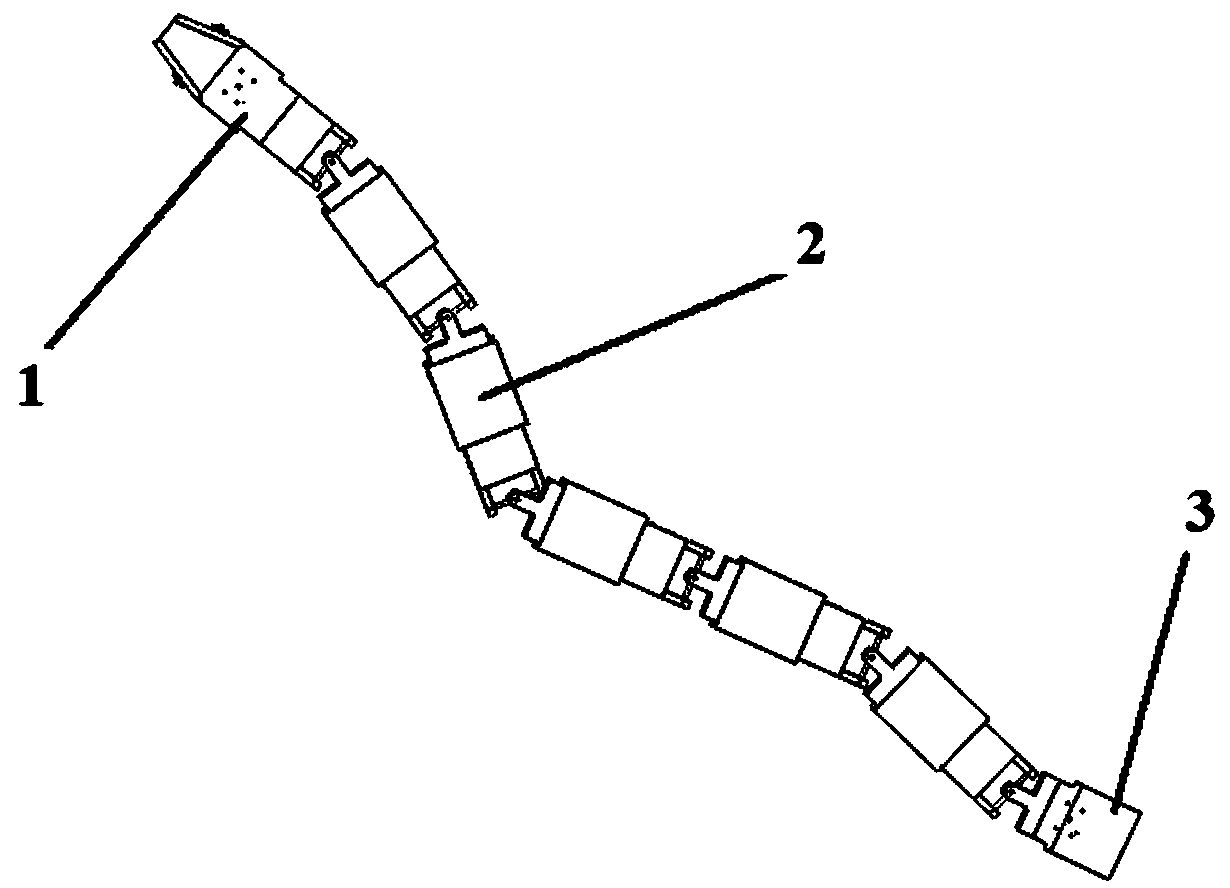

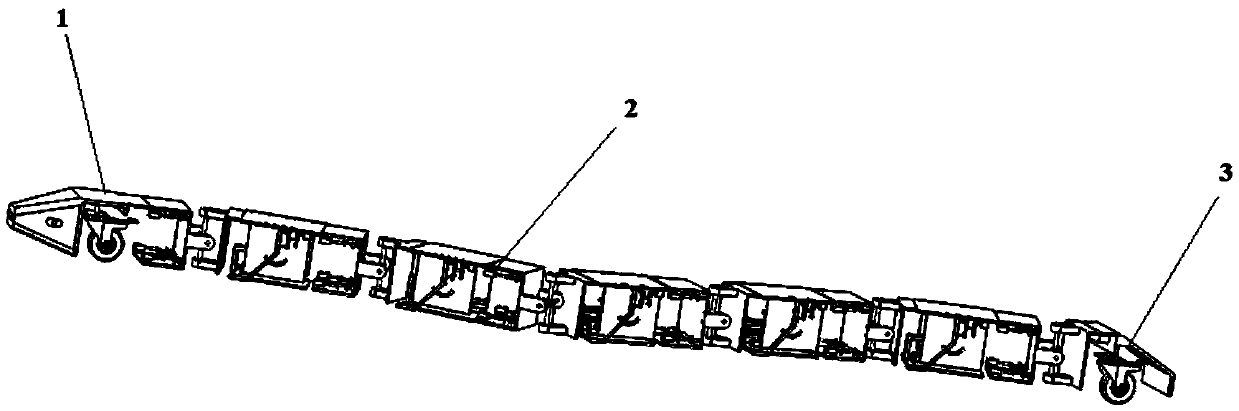

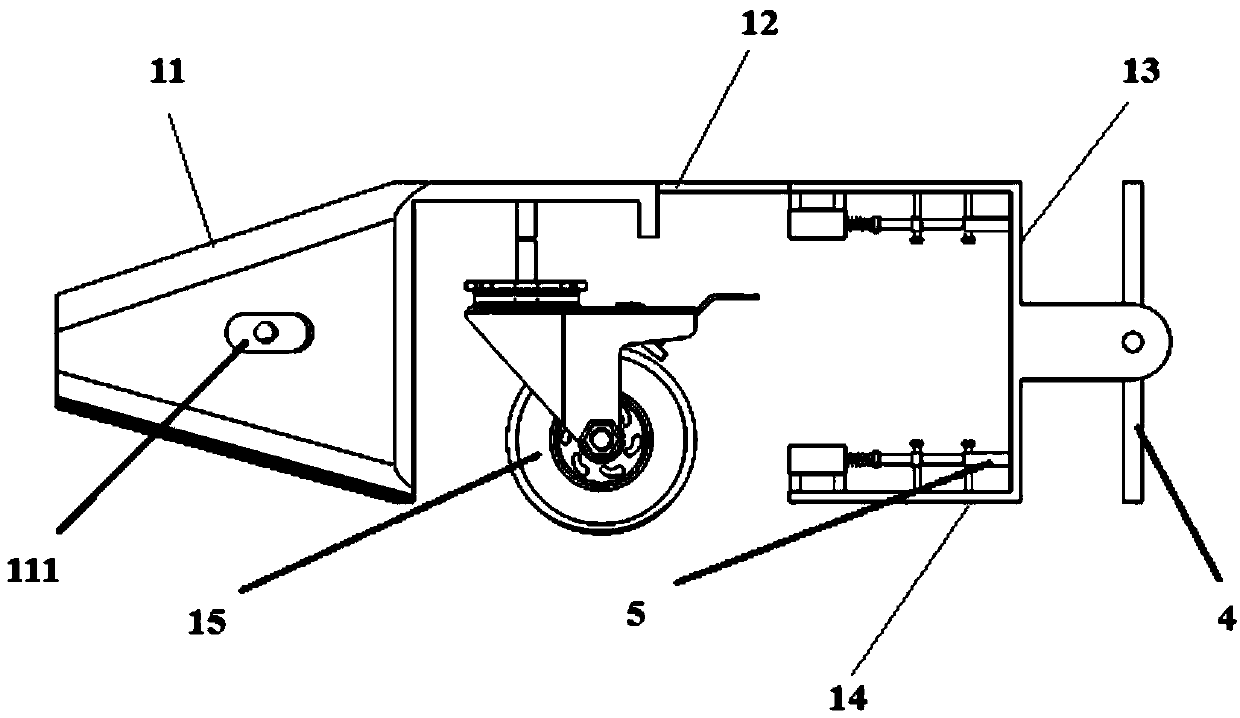

[0057] Such as Figures 1 to 13 As shown, the present embodiment provides a magnetically driven micro-motion amplified robotic snake, which includes a snake head 1, a snake body 2 and a snake tail 3 connected to each other, and the gaps between the snake head 1 and the snake body 2 and between the snake body 2 and the snake tail 3 are Connect by cross shaft 4; Snakehead 1 comprises streamlined snakehead front portion 11, the binocular vision camera 111 that is installed in the snakehead front portion 11 both sides, the horizontal snakehead top plate 12 that connects snakehead front portion 11, vertically connects the snakehead top plate 12 rear end The snake head rear plate 13 and the snake head bottom plate 14 vertically connected to the snake head rear plate 13 and positioned at the bottom of the snake head top plate 12 are all provided with a twisting drive unit 5 connected to the snake head rear plate 13 on the snake head top plate 12 and the snake head bottom plate 14; Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com