A kind of germanate long afterglow luminescent material and preparation method thereof

A technology of long-lasting luminescence and germanate, which is applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems that the luminescence band is limited to blue-green light, the luminescence performance is not as good as that of aluminates, and the requirements for equipment and environment are higher, reaching Increased range of luminous colors, duration of strong afterglow, effects of enhanced afterglow performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] According to another preferred embodiment of the present invention, the present invention also provides a method for preparing a germanate long-lasting luminescent material, the preparation method is used to prepare the aforementioned germanate long-lasting luminescent material, and the preparation method includes Follow the steps below:

[0035] Mixing and grinding: Weigh the raw materials according to the stoichiometric ratio of each element, put the mixed raw materials in an agate mortar, add absolute ethanol or deionized water to grind at room temperature for 1-2 hours, and then put them in an oven for drying Obtain mixed powder. Preferably, the drying temperature of the mixed raw materials in the oven is 50-100°C. Preferably, the raw material includes Ga 2 o 3 、GeO 2 and Ln 3+ oxides or nitrates. Among them, Ln is a trivalent rare earth ion and / or a trivalent transition metal ion, and the raw material Ga 2 o 3 and raw GeO 2 The purity is 99.9%. Preferably...

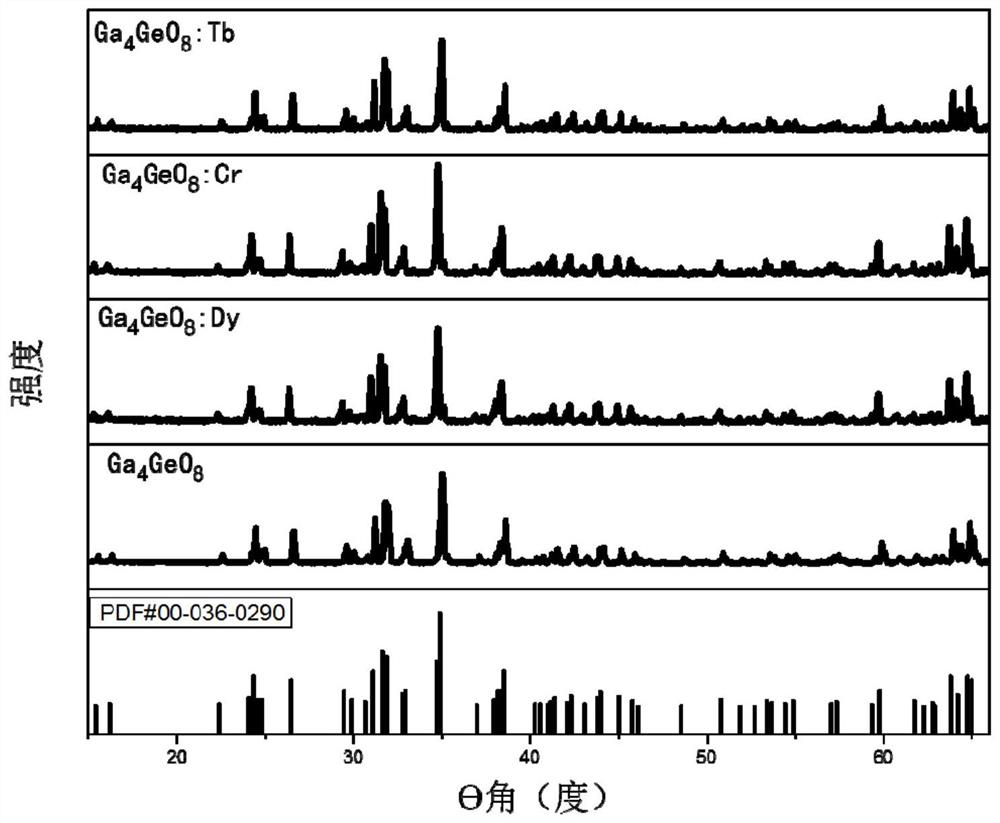

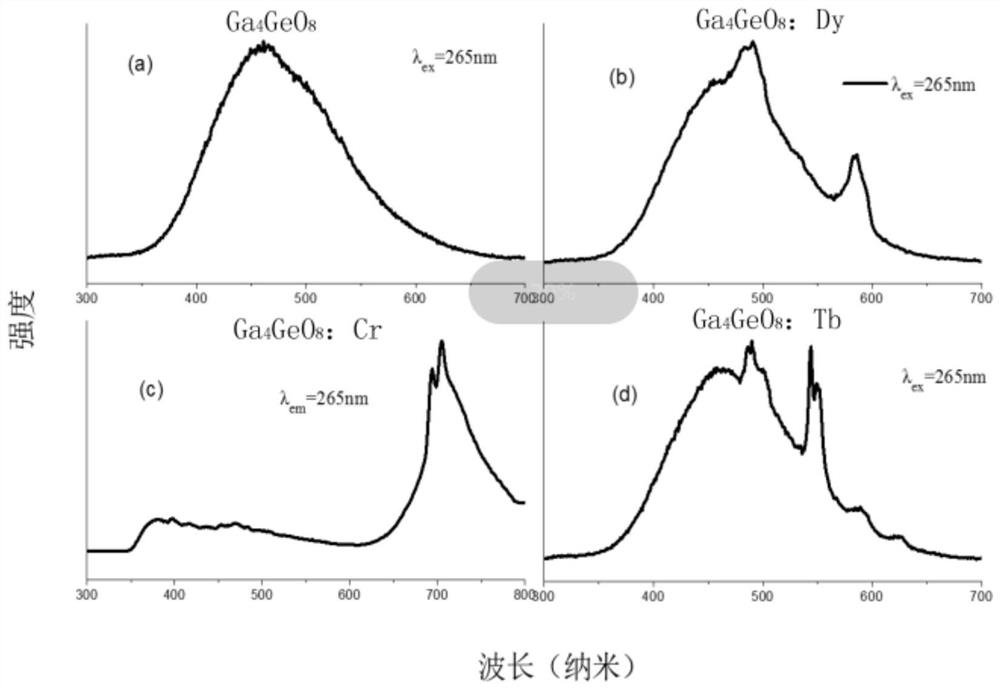

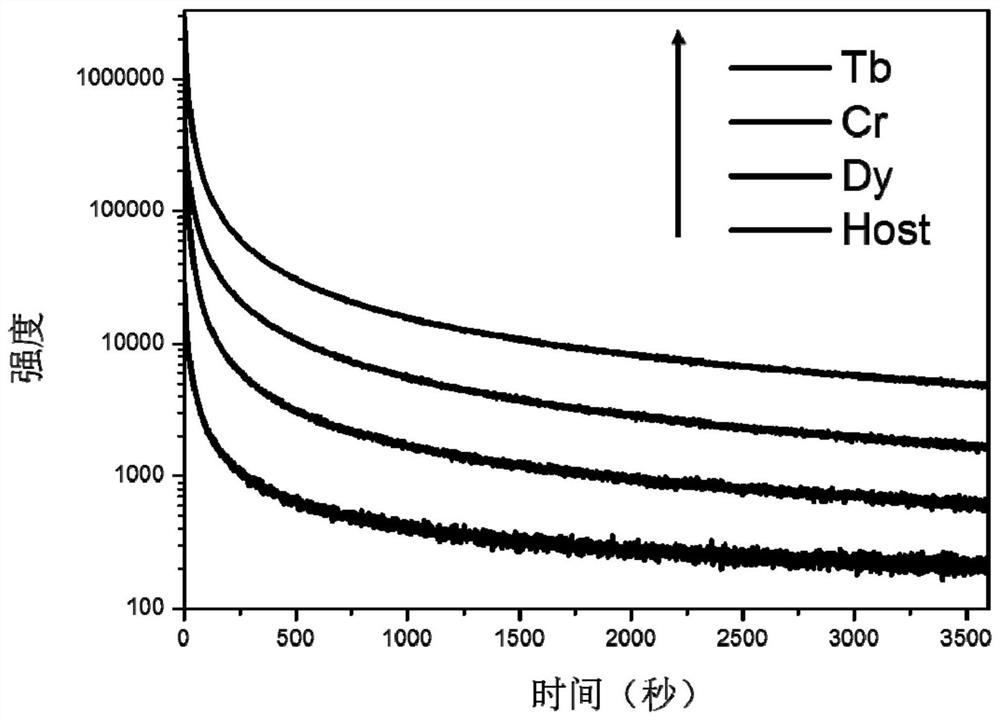

Embodiment 1

[0043] Take Ga 2 o 3 、GeO 2 and Tb 4 o 7 As raw material, take 0.78178gGa respectively 2 o 3 , 0.218218gGeO 2 and 0.003898gTb 4 o 7 , mix the above raw materials and place them in an agate mortar, add absolute ethanol to grind at room temperature for 1-2 hours, and then put them into an oven at 50-100°C to dry to obtain the mixed powder. Put the mixed powder in an alumina crucible, raise the temperature to 800°C at a rate of 1-10°C in the atmosphere, and burn for 2 hours to obtain a pre-fired sample. The pre-fired sample was ground and placed in an alumina crucible, raised to 1300°C at a rate of 1-10°C in an air atmosphere, burned for 4 hours, and then naturally cooled to room temperature with the furnace. The cooled sample is ground again and sieved with a 20-50 mesh sieve to obtain a long afterglow emitting material with a composition of Ga4GeO8:1%Tb3+.

Embodiment 2

[0045] Take Ga 2 o 3 、GeO 2 and Dy 2 o 3 As raw material, take 0.78178gGa respectively 2 o 3 , 0.218218gGeO 2 and 0.003898gDy 2 o 3 , mix the above raw materials and place them in an agate mortar, add absolute ethanol to grind at room temperature for 1-2 hours, and then put them into an oven at 50-100°C to dry to obtain the mixed powder. Put the mixed powder in an alumina crucible, raise the temperature to 800°C at a rate of 1-10°C in the atmosphere, and burn for 2 hours to obtain a pre-fired sample. The pre-fired sample was ground and placed in an alumina crucible, raised to 1300°C at a rate of 1-10°C in an air atmosphere, burned for 4 hours, and then naturally cooled to room temperature with the furnace. The cooled sample is ground again and sieved with a 20-50 mesh screen to obtain a long afterglow emitting material with the composition Ga4GeO8:1%Dy3+.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com