Viscoelastic rotary damping support and working method thereof

A technology of rotational damping and viscoelasticity, which is applied in protective buildings/shelters, building components, fire protection, etc., to achieve strong energy dissipation and increase bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

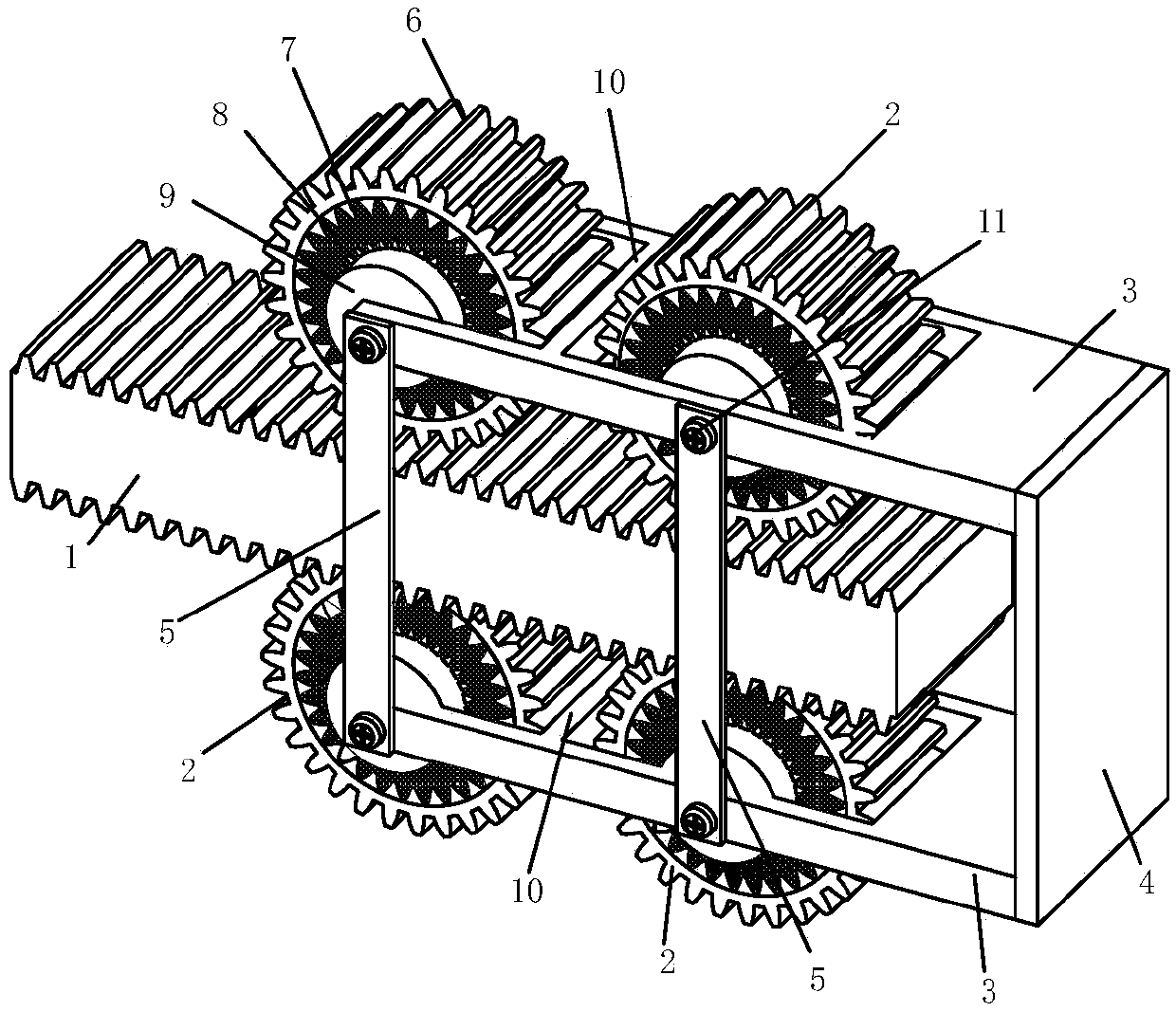

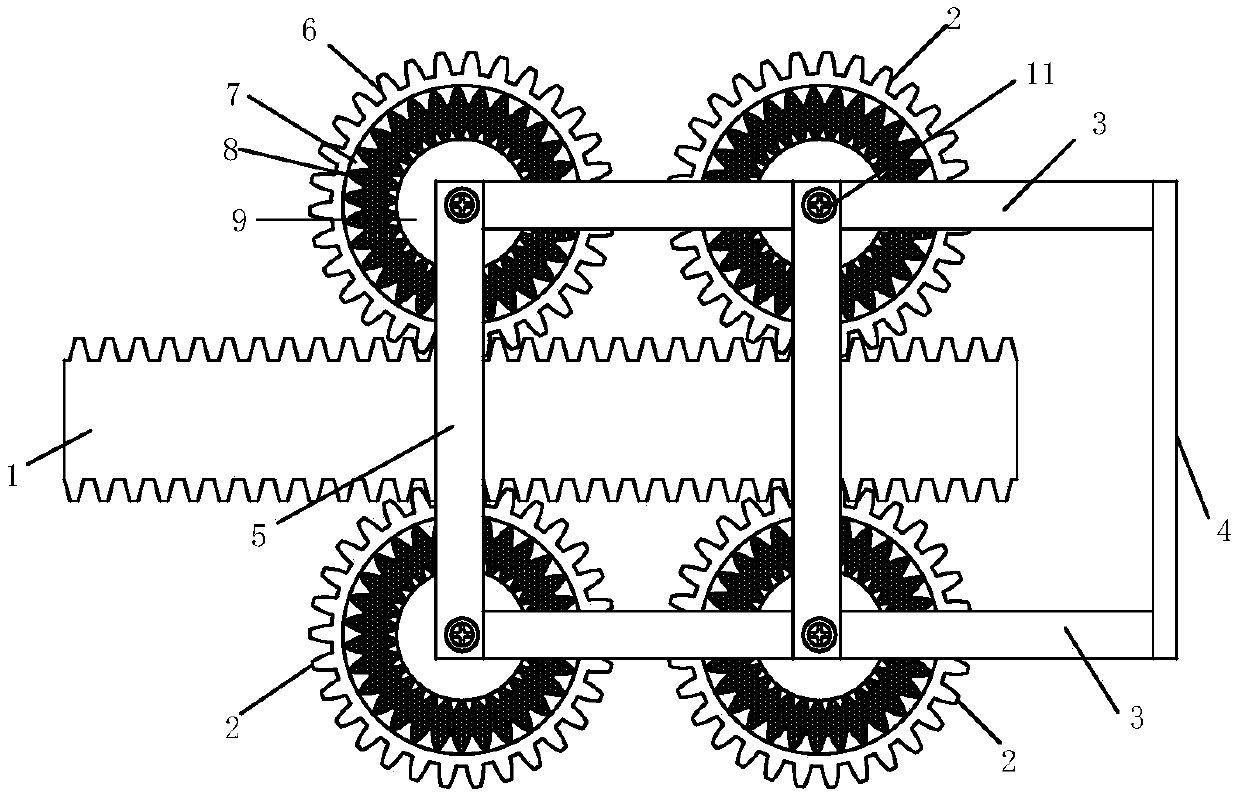

[0042] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0043] Such as figure 1 As shown, a viscoelastic rotational damping support, including:

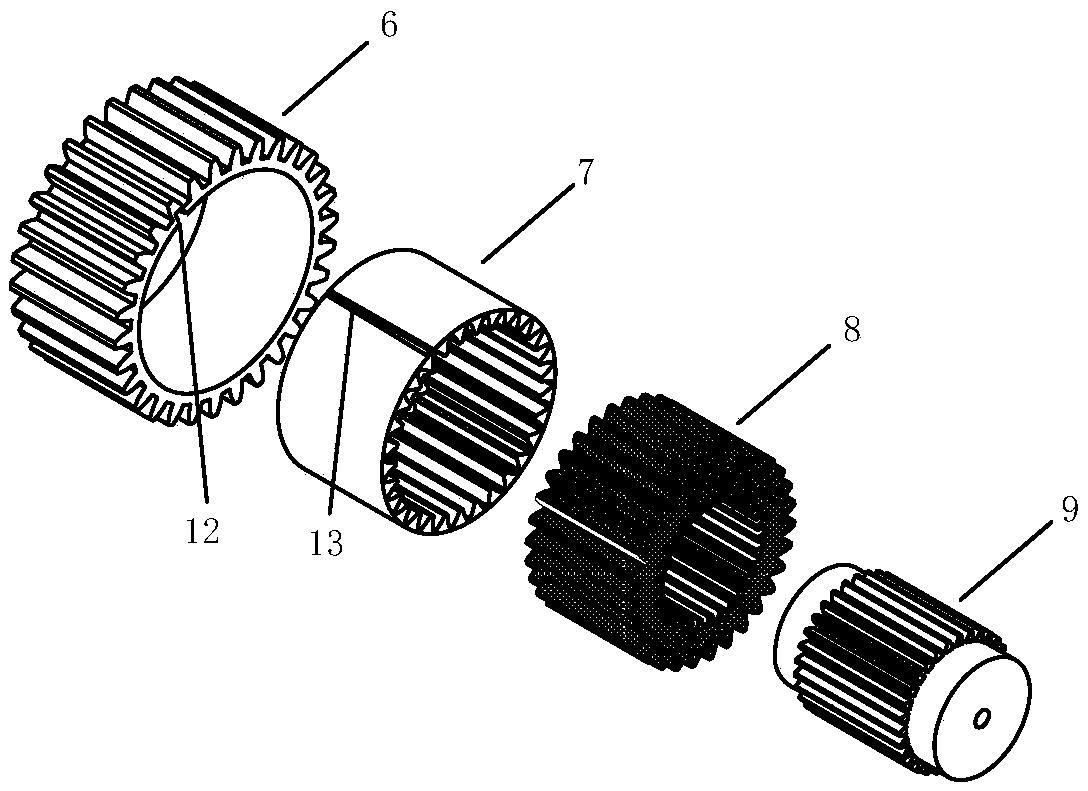

[0044] A double-sided toothed rack 1, on the two tooth surfaces of the rack 1 are symmetrically provided with at least two rotational damping units meshed with it for transmission, and each rotational damping unit includes: axially socketed together The external gear 6, the shaft sleeve 7 and the fixed shaft 9, wherein,

[0045] The external gear 6 is used to mesh with the rack 1;

[0046] The outer ring of the shaft sleeve 7 is keyed to the inner ring of the external gear 6,

[0047] The inner ring surface of the shaft sleeve 7 and the outer ring surface of the fixed shaft 9 have the same circle center, and there is an annular cavity for placing a viscoelastic damping material between the inner ring surface of the shaft sleeve 7 and the oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com