Simple-partial cooling cycle compact type supercritical carbon dioxide cycle energy supply system for small sodium reactors

A technology of carbon dioxide and cooling cycle, which is applied in the conversion of reactor thermal energy into mechanical energy, nuclear power generation, steam engine installations, etc. It can solve the problems of large equipment occupation space, low thermal cycle efficiency, and potential safety hazards in sodium-hydraulic heat transfer, etc. Achieve the effect of reducing the number of generators and reducing the size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

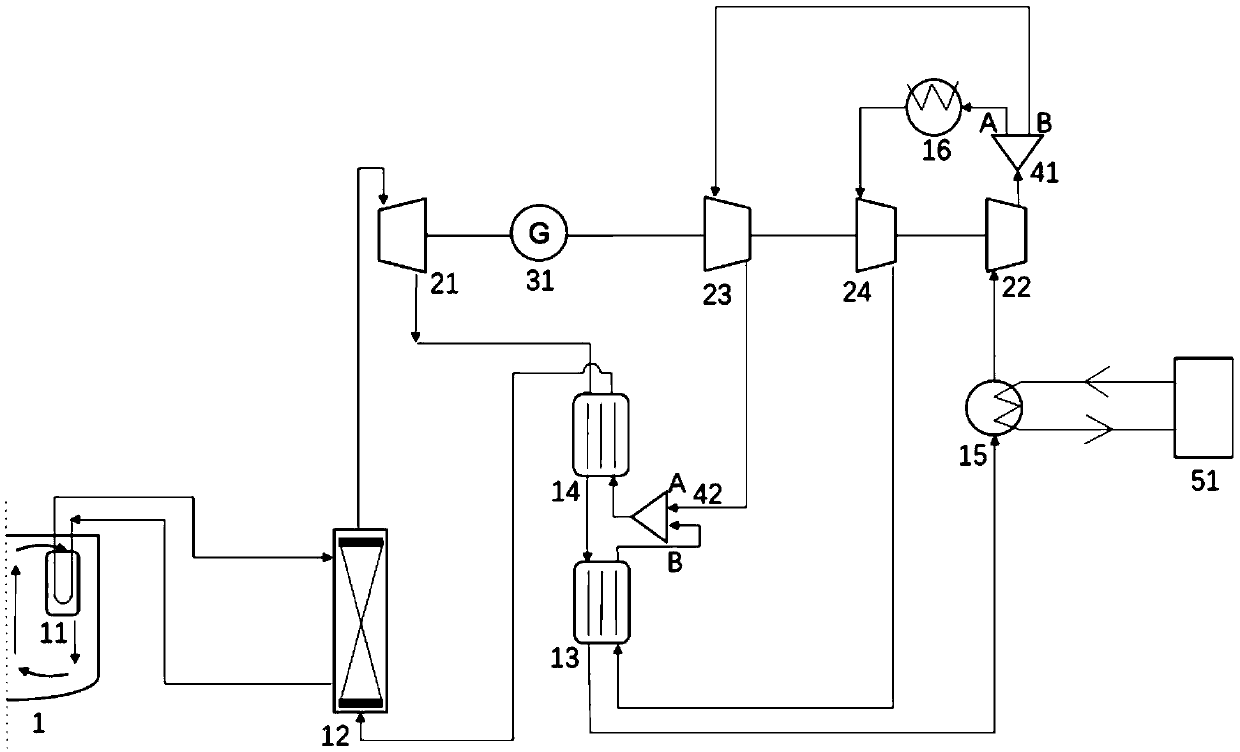

[0021] Specific implementation mode 1, such as figure 1 As shown, the simple-partial cooling cycle compact supercritical carbon dioxide cycle energy supply system of the small-scale sodium stack of the present embodiment includes a heat source, a first loop, a second loop, a sodium-sodium heat exchanger 11, and a sodium-carbon dioxide heat exchanger 12. Main cooler 15 and heating equipment 51;

[0022] The first loop absorbs the heat from the heat source through the sodium-sodium heat exchanger 11, and then exchanges the heat to the second loop through the sodium-carbon dioxide heat exchanger 12. The second loop uses the heat to generate power, and the remaining heat after power generation passes through the main cooler. 15 is exchanged to the heating equipment 51 to provide heat energy for users;

[0023] The second circuit is provided with turbine 21, generator 31, main compressor 22, high-temperature sub-compressor 23 and low-temperature sub-compressor 24, turbine 21 drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com