Detecting method for sample crystal grain and microstructure of GH4648 board

A plate sample and microstructure technology, applied in the field of testing and testing, can solve the problems of increasing the difficulty of the sample preparation process, incapable of sample inlay and sample preparation, etc., to improve the corrosion efficiency and detection efficiency, improve the preparation quality and efficiency, The effect of improving the finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

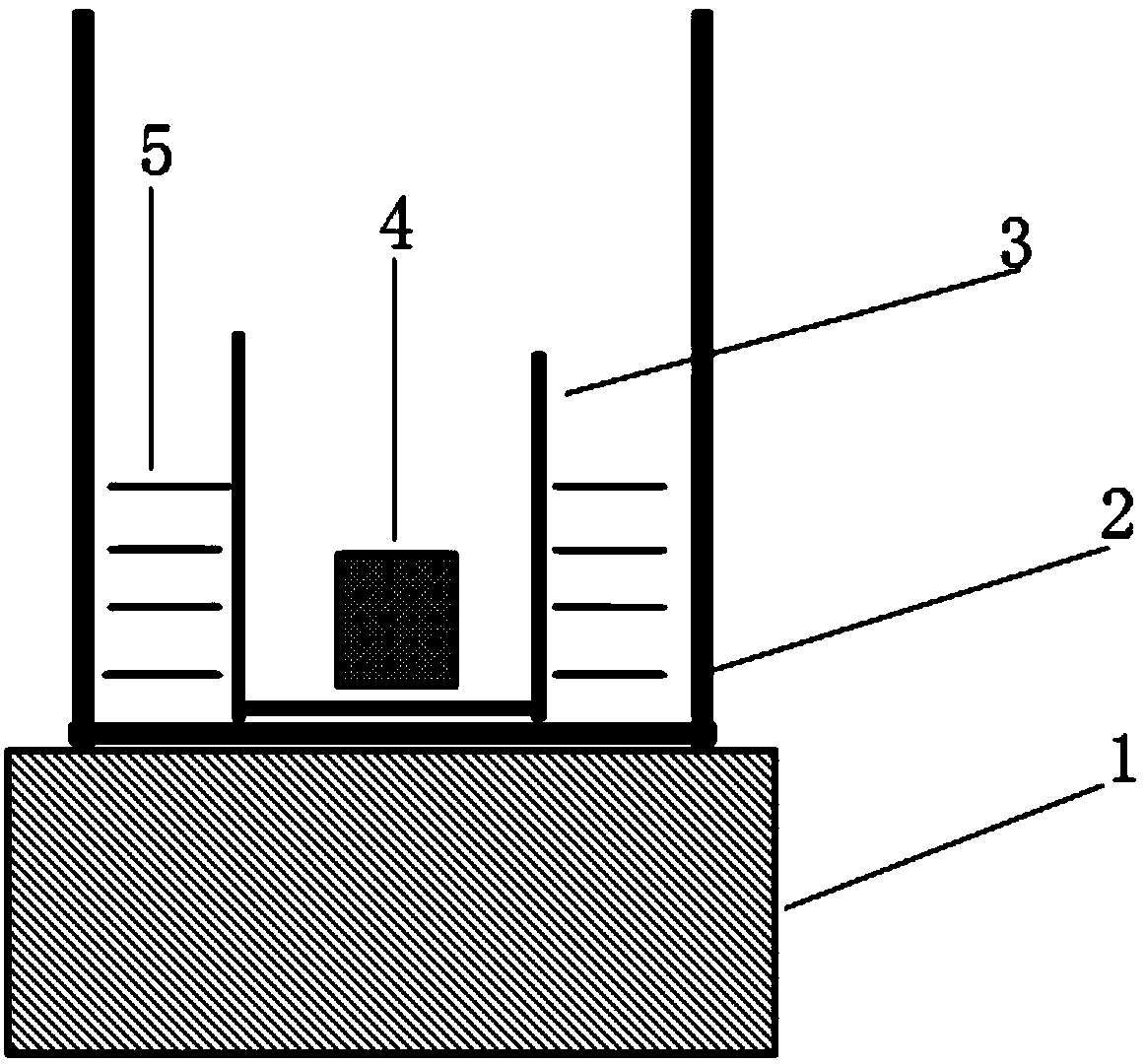

[0025] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings, but the required protection scope is not limited to the description;

[0026] Such as figure 1 Shown, detection method concrete steps of the present invention are as follows:

[0027] (1) After grinding the GH4648 plate test piece, put every 5 pieces into the sample mounting mold for sample mounting, and choose hot mounting or cold mounting according to the size of the test piece.

[0028] (2) Put the inlaid sample on the grinding and polishing equipment for grinding and polishing. After the grinding and polishing of the sample, dry it with hot air. There should be no visible grinding and polishing marks on the side light; if there are grinding and polishing marks, Needs to be re-polished.

[0029] (3) Corrosion of the specimen, see figure 1 As shown, first add an appropriate amount of water into the large beaker 2, and the water surface 5 must...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com