Self-standing impact pressure resistance test device

A technology of impact withstand voltage and test equipment, which is applied in the direction of measuring equipment, measuring equipment casing, and testing dielectric strength, etc., which can solve the problems of uneven weight of the impact generator, inconvenient placement process, low test efficiency, etc., and achieve shortening The effect of test cycle, compact structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

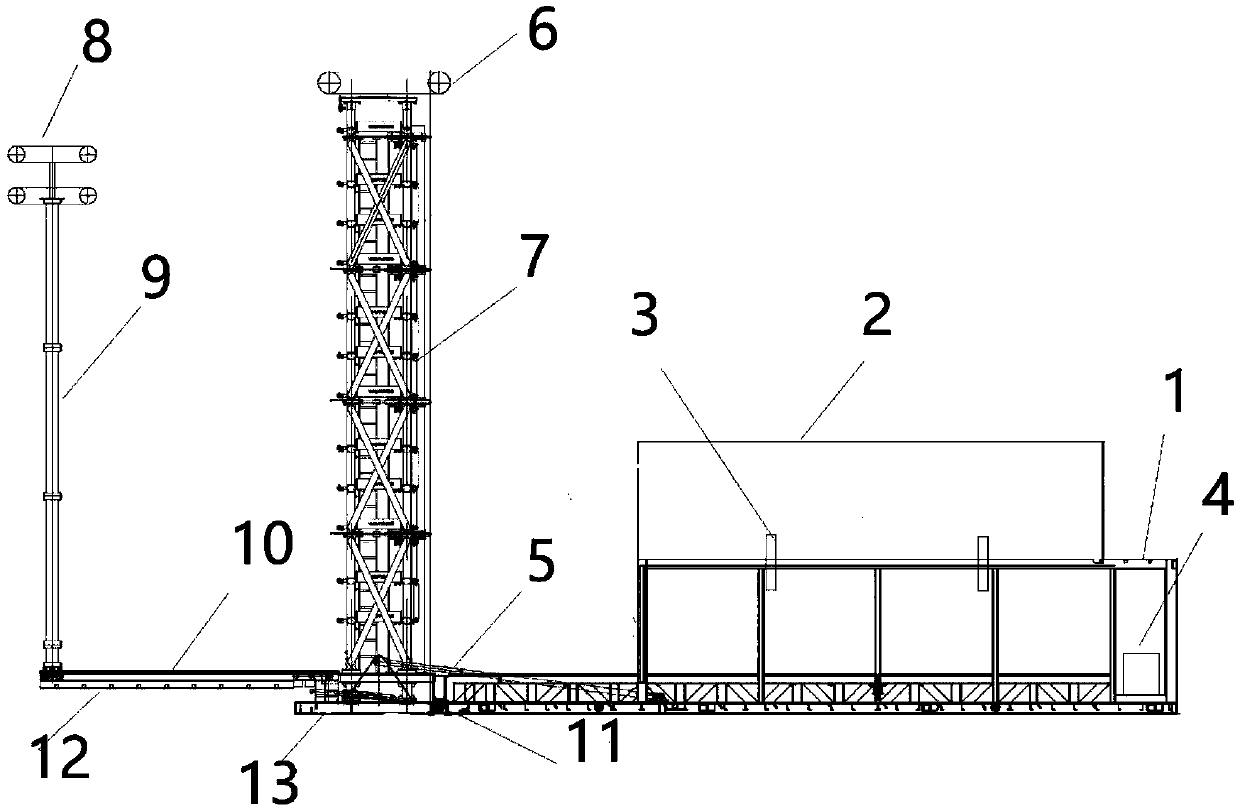

[0031] Such as figure 1 As shown, in this embodiment, a self-supporting impact pressure test device includes a container 1, a top cover 2, a rear cover plate 13, a top cover hydraulic ejector rod 3, a hydraulic rod 5, a hydraulic cylinder 13, and an impulse voltage generator Body 7, voltage divider 9, rail 10; the impulse voltage generator body 7 and voltage divider 9 are placed flat in the container 1, the rail 10 is hinged to the bottom end of the impulse voltage generator body 7, and the voltage divider 9 is slidably connected On the track 10, the container 1 includes a front cover, a rear cover 13, a bottom plate, side panels on both sides opposite to the bottom plate and a top cover 2, and one side of the front cover of the container 1, the rear cover 13 is hinged to the bottom plate One side of the top cover 2 of the container 1 is hinged to the top side of the container 1, and a top cover hydraulic jack 3 is provided between the side of the top cover 2 facing the contai...

Embodiment 2

[0033] Such as figure 1 As shown, the difference between this embodiment and Embodiment 1 is that the impulse voltage generator body 7 is composed of a plurality of insulating components, and the plurality of insulating components are stacked and connected to form a tower structure. The structure is mainly composed of four epoxy columns and an epoxy cylinder for installing discharge balls. The epoxy columns are made into one level every 770 mm according to the requirements of the impulse voltage generator, and two dry capacitors and resistors are installed on each level. and other components. Since the impulse voltage generator body equipment of the impulse voltage generator is placed horizontally in the container when stored, and vertically when used, in addition to the bottom support required for horizontal placement, the four main columns are subjected to huge bending moments and shear during the overturning process. Shearing force, the plurality of insulating components a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com