Manufacturing technology method for self-adhesive label

A manufacturing method and label technology, which are applied in the directions of adhesives, instruments, identification devices, etc., can solve the problems of substrate deformation, volume shrinkage, and affecting the printing effect of substrates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to illustrate the technical solution of the present invention more clearly, the present invention will be briefly introduced below using examples. Obviously, what is described below is only an embodiment of the present invention. For those of ordinary skill in the art, On the premise of paying creative efforts, other technical solutions can also be obtained according to these embodiments, which also belong to the disclosure scope of the present invention.

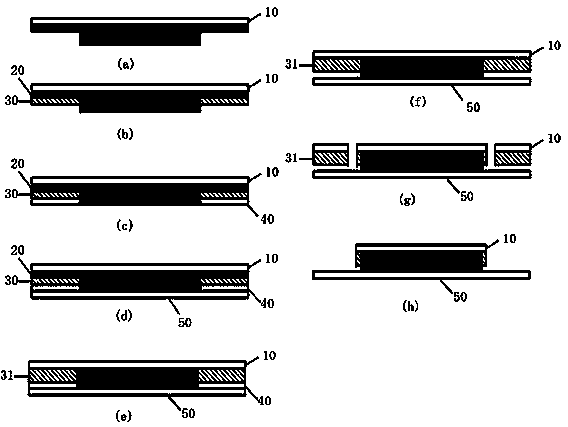

[0017] A kind of self-adhesive label making method of the embodiment of the present invention, such as figure 1 shown in , see first figure 1 (a), coating the first adhesive layer 20 on the label substrate 10 , wherein the height of the center of the first adhesive layer 20 is higher than that of both sides. The central height and thickness of the first adhesive layer can be 15 μm to 20 μm, and the height on both sides can be 10 μm to 15 μm; the first adhesive can be acrylic adhesive, rubber adhesive or sil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com