An interconnection structure of a solar wing cell assembly and its preparation process

A technology of solar wings and solar cells, which is applied to solar panel accessories, wings, electrical components, etc., can solve the problems of unfavorable laying area utilization, complex structure, improvement and other problems, so as to improve the utilization rate of the laying area of components, and improve the efficiency of the laying area. The effect of shortening the distance between cloth and reducing the weight of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

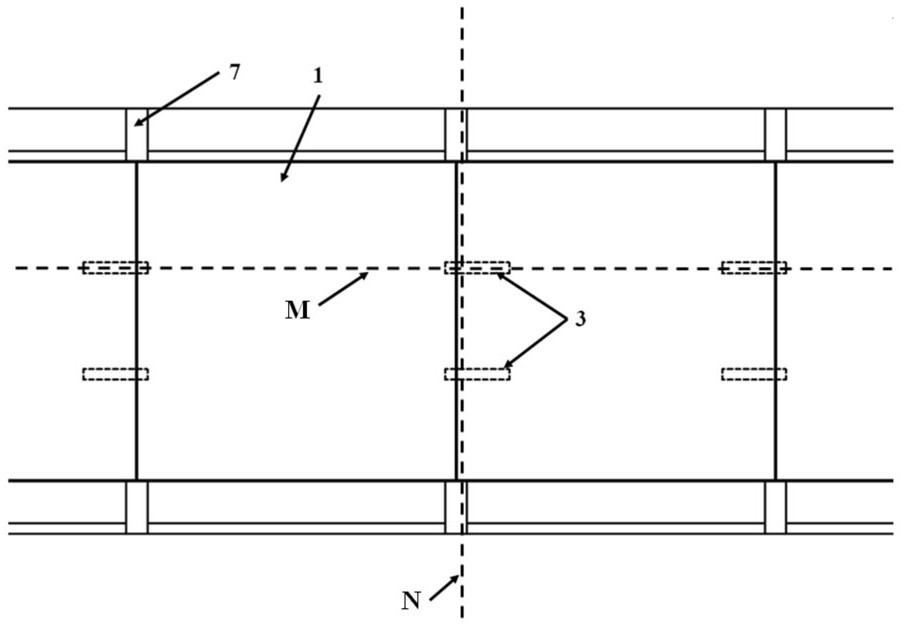

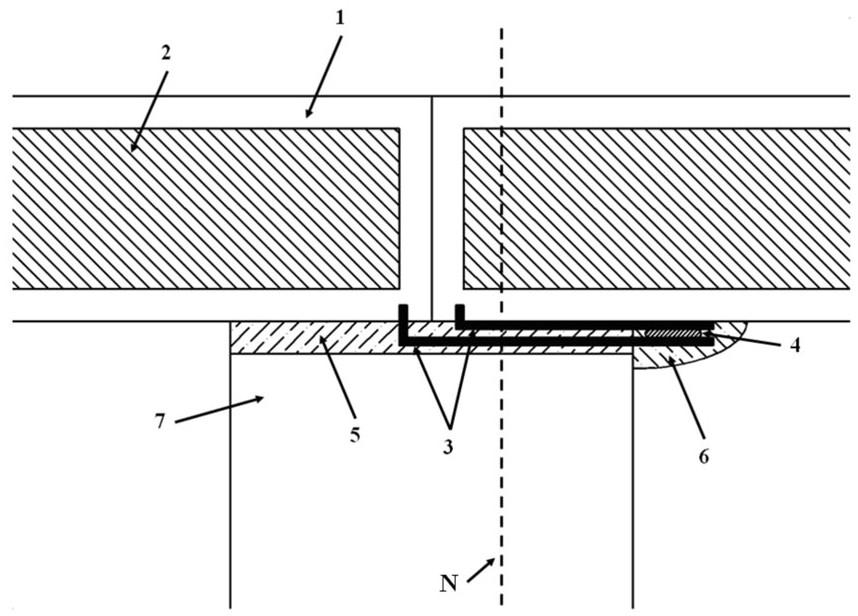

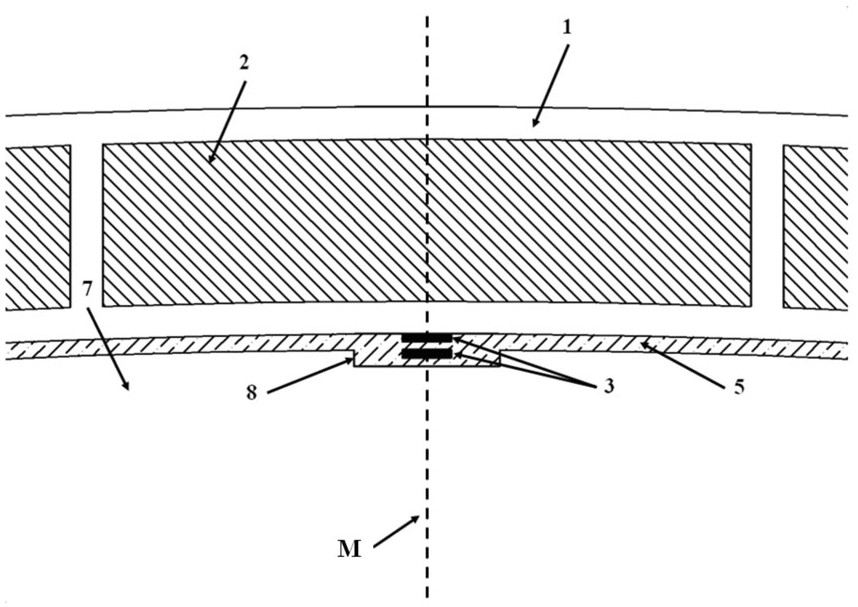

[0058] An interconnection structure of solar wing battery components of the present invention, comprising: two pairs of positive and negative lead-out wires provided by a single battery component, the positive and negative lead-out lines are flat conductor lead-out lines, and the lead-out points of the positive and negative lead-out wires are Located at both ends of the battery assembly along the span of the wing.

[0059] The lead-out points of the lead-out wire pairs interconnected by adjacent battery components are set close to the joint surface of adjacent battery components, and are relatively arranged on both sides of the joint face of adjacent battery components. Lead out along the same side direction, close to the back of the battery module in an overlapping position relationship, and finally connect.

[0060] Adjacent battery assemblies are connected to wing ribs.

[0061] For details of the interconnection structure in this embodiment, please refer to Figure 1 ~ F...

Embodiment 2

[0076] An interconnection structure of solar wing battery components of the present invention, comprising: two pairs of positive and negative lead-out wires provided by a single battery component, the positive and negative lead-out lines are flat conductor lead-out lines, and the lead-out points of the positive and negative lead-out wires are Located at both ends of the battery assembly along the span of the wing.

[0077] The lead-out points of the lead-out wire pairs interconnected by adjacent battery components are set close to the joint surface of adjacent battery components, and are relatively arranged on both sides of the joint face of adjacent battery components. Lead out along the same side direction, close to the back of the battery module in an overlapping position relationship, and finally connect.

[0078] Adjacent battery assemblies are connected to wing ribs.

[0079] For details of the interconnection structure in this embodiment, please refer to Figure 1 ~ F...

Embodiment 3

[0095] An interconnection structure of solar wing battery components of the present invention, comprising: two pairs of positive and negative lead-out wires provided by a single battery component, the positive and negative lead-out lines are flat conductor lead-out lines, and the lead-out points of the positive and negative lead-out wires are Located at both ends of the battery assembly along the span of the wing.

[0096] The lead-out points of the lead-out wire pairs interconnected by adjacent battery components are set close to the joint surface of adjacent battery components, and are relatively arranged on both sides of the joint face of adjacent battery components. Lead out along the same side direction, close to the back of the battery module in an overlapping position relationship, and finally connect.

[0097] Adjacent battery assemblies are connected to wing ribs.

[0098] For details of the interconnection structure in this embodiment, please refer to Figure 1 ~ F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com