A DC series excitation motor control system and method

A series excitation motor and control system technology, applied in the direction of DC motor rotation control, DC motor speed/torque control, control system, etc., can solve the problems of low energy feedback efficiency, DC motor limitation, poor protection ability, etc. The effect of large torque, strong overload capacity and high energy feedback

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

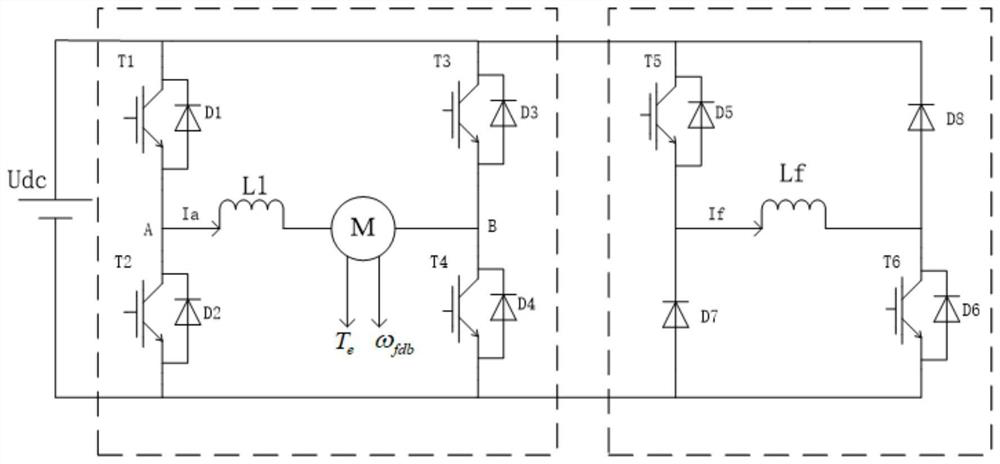

[0071] A DC series motor control method:

[0072] When the DC motor M is rotating forward;

[0073] When the first switch T1 and the fourth switch T4 are turned on, the direction of the armature current see Figure 4 , U AB The voltage across the supply voltage U DC , the power supply provides energy to the DC motor M, the armature current starts from the positive pole of the power supply, flows through the first switch T1, the smoothing reactor L1, and the DC motor M, and returns to the negative pole of the power supply from the fourth switch T4;

[0074] After the DC motor M rotates in the forward direction, when the second switch T2 and the third switch T3 are turned on, the direction of the armature current refers to Figure 5 , U AB The voltage across the terminal and the supply voltage U DC On the contrary, because the direction of the armature current remains unchanged, the armature current flows from the smoothing reactor L1, DC motor M, and the third switch T3 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com