Method for realizing ultra-high precision circular inductosyn

A technology of circular induction synchronizer and induction synchronizer, which is applied in the field of realizing ultra-high precision circular induction synchronizer, and can solve the problems affecting the engraved line processing of the synchronizer, the large size of the multi-tooth indexing table, and the limitation of the pole number of the engraved line, etc. Achieve the effects of variable and flexible number of marking poles, improved precision level, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the embodiments and with reference to the accompanying drawings.

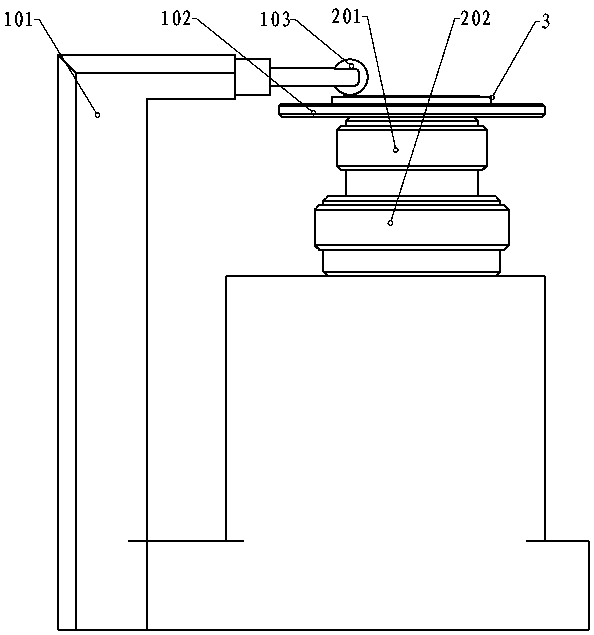

[0031] like figure 2 As shown, the multi-tooth indexing table 202 of X teeth and the multi-tooth indexing table 201 of Y teeth constitute a differential indexing system, and the coaxiality of the two multi-tooth indexing tables is required to be better than 0.003mm. To adjust the differential indexing system, it is required that the accuracy of a single multi-tooth indexing table is not greater than 0.2", and the comprehensive differential accuracy is not greater than 0.4", where: X>Y>300, and X is an integer multiple of 180, then the two The angular resolution of the difference is [360(X-Y) / XY]°.

[0032] like figure 2 As shown in the figure, the differential indexing system is installed on the synchronizer marking tooling 102 in the marking processing system, and joint adjustment is carried out to ensure that the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com