Automatic assembling machine of encoder shock-proof rings

An assembly machine and encoder technology, applied in grinding machines, metal processing, metal processing equipment, etc., can solve the problems of low assembly efficiency, high labor cost, uneven product quality, etc., to ensure product quality, reduce labor costs, The effect of improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

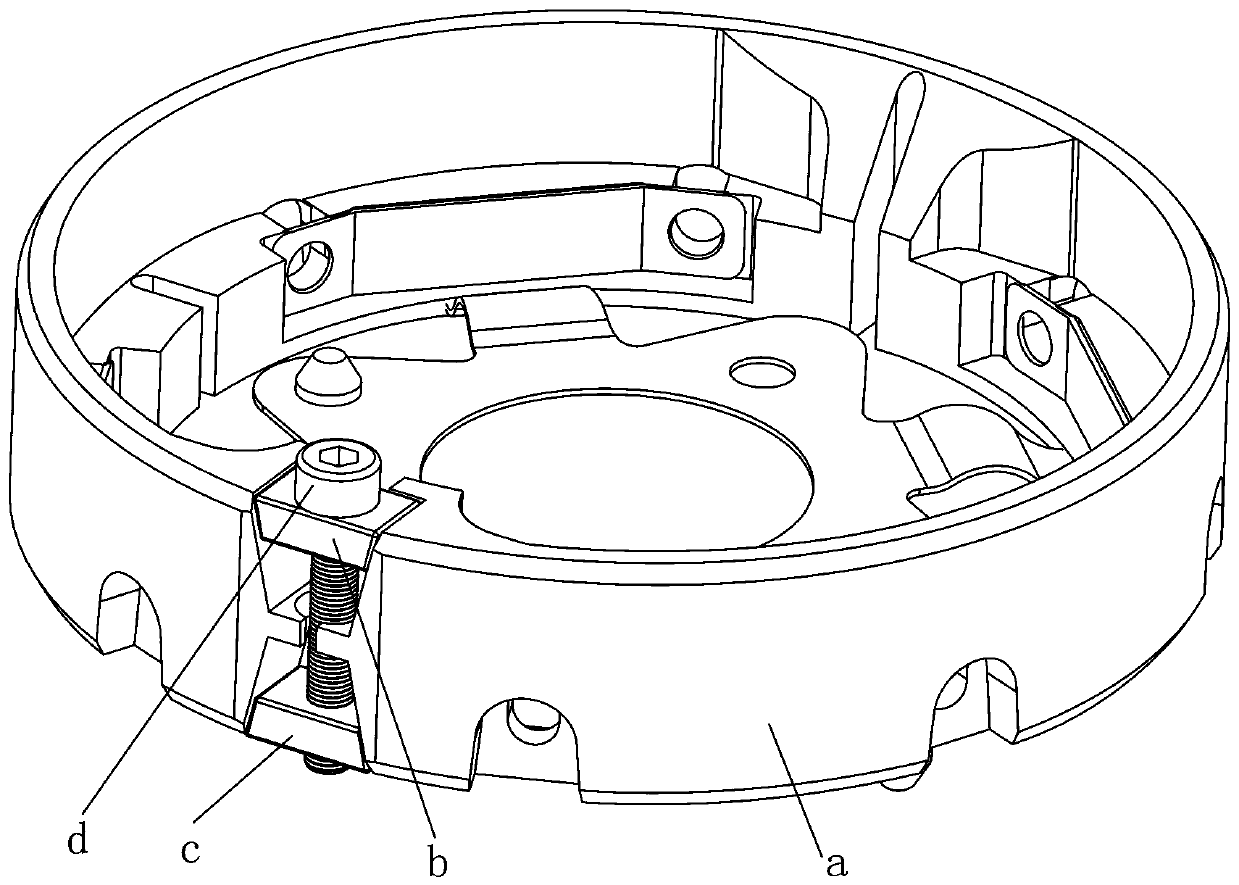

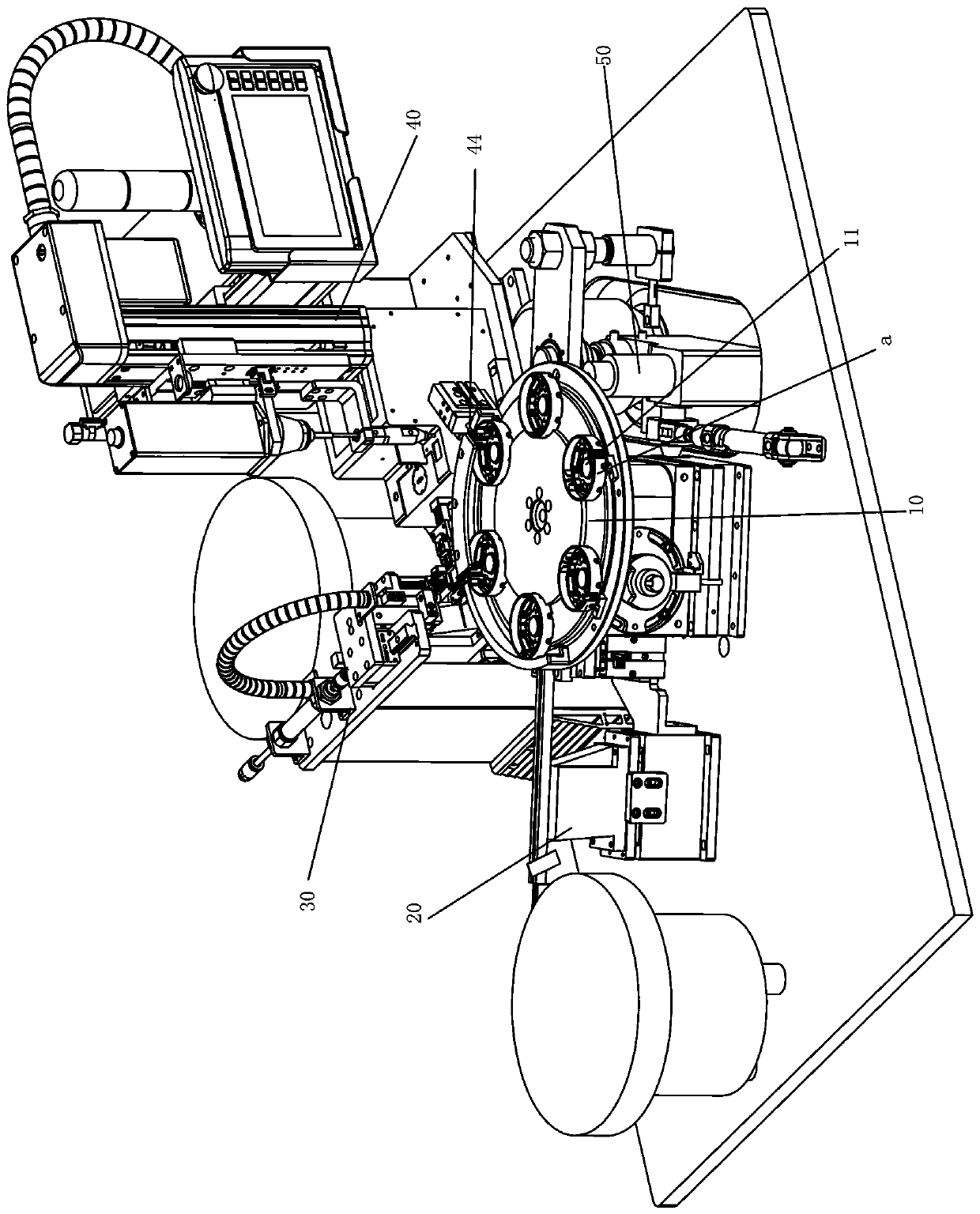

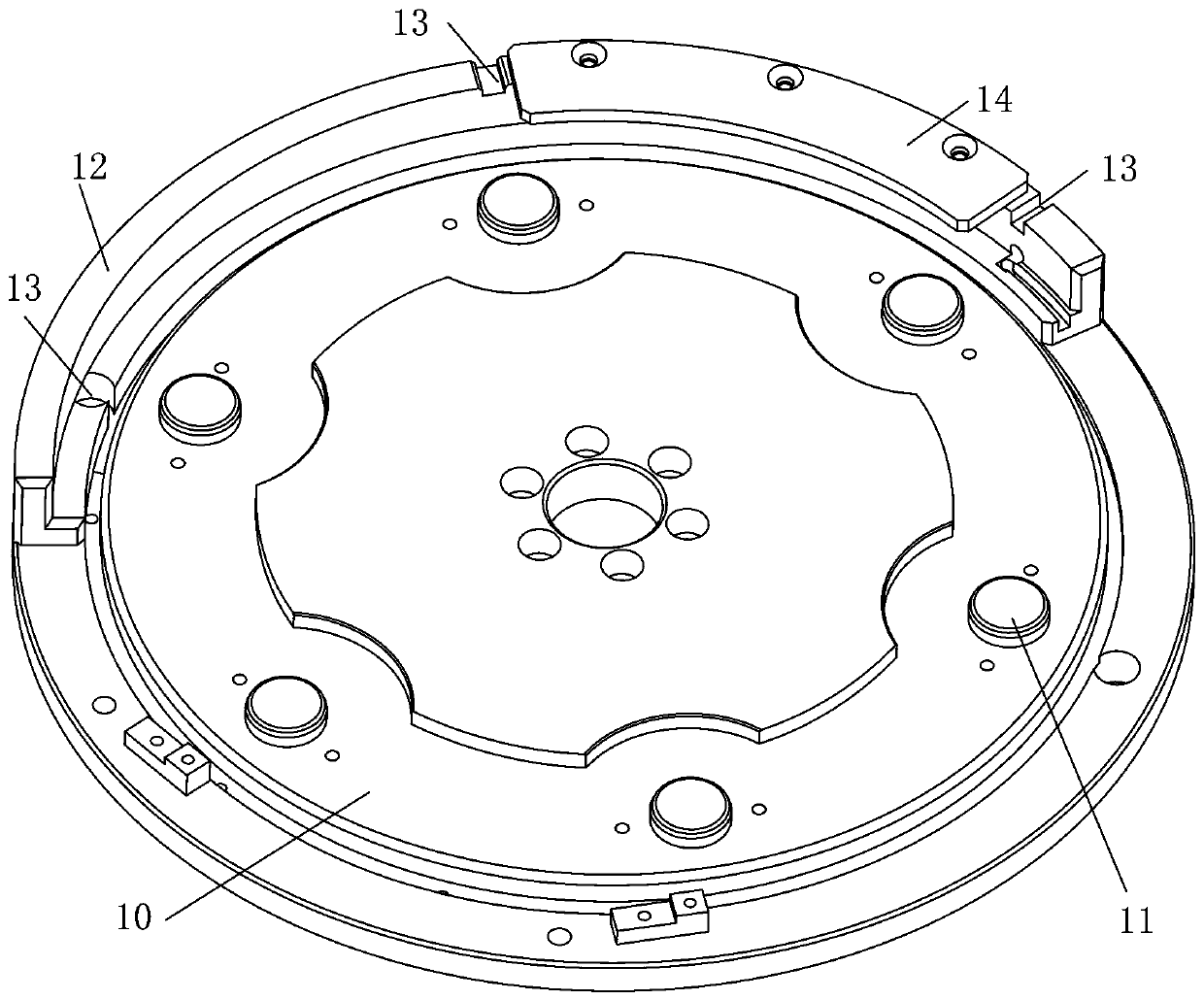

[0027] like figure 2 As shown, the embodiment provided by the present invention is an automatic assembly machine for an encoder shock absorber, which includes a turntable 10, a number of jigs 11 are evenly distributed on the edge of the turntable 10, and lower wedges are sequentially arranged on the side of the turntable 10 along the rotation direction of the turntable 10. Block nut feeding mechanism 20 , upper wedge nut feeding mechanism 30 , bolt feeding locking mechanism 40 and thread removing mechanism 50 .

[0028] like image 3 As shown, a retaining wall 12 is provided outside the edge of the turntable 10, and the retaining wall 12 is provided with assembly holes 13 corresponding to the positions of the lower wedge nut feeding mechanism 20, the upper wedge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com