Pneumatic hot-press welding machine

A hot-pressing welding and pneumatic technology, applied in the field of pneumatic hot-pressing welding machines, can solve the problems of fatigue damage of parts, inconvenient maintenance of driving mode, large reaction force of mechanical parts, etc., to achieve small pressure damage and easy auxiliary fixation. The effect of placing the mold and the uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

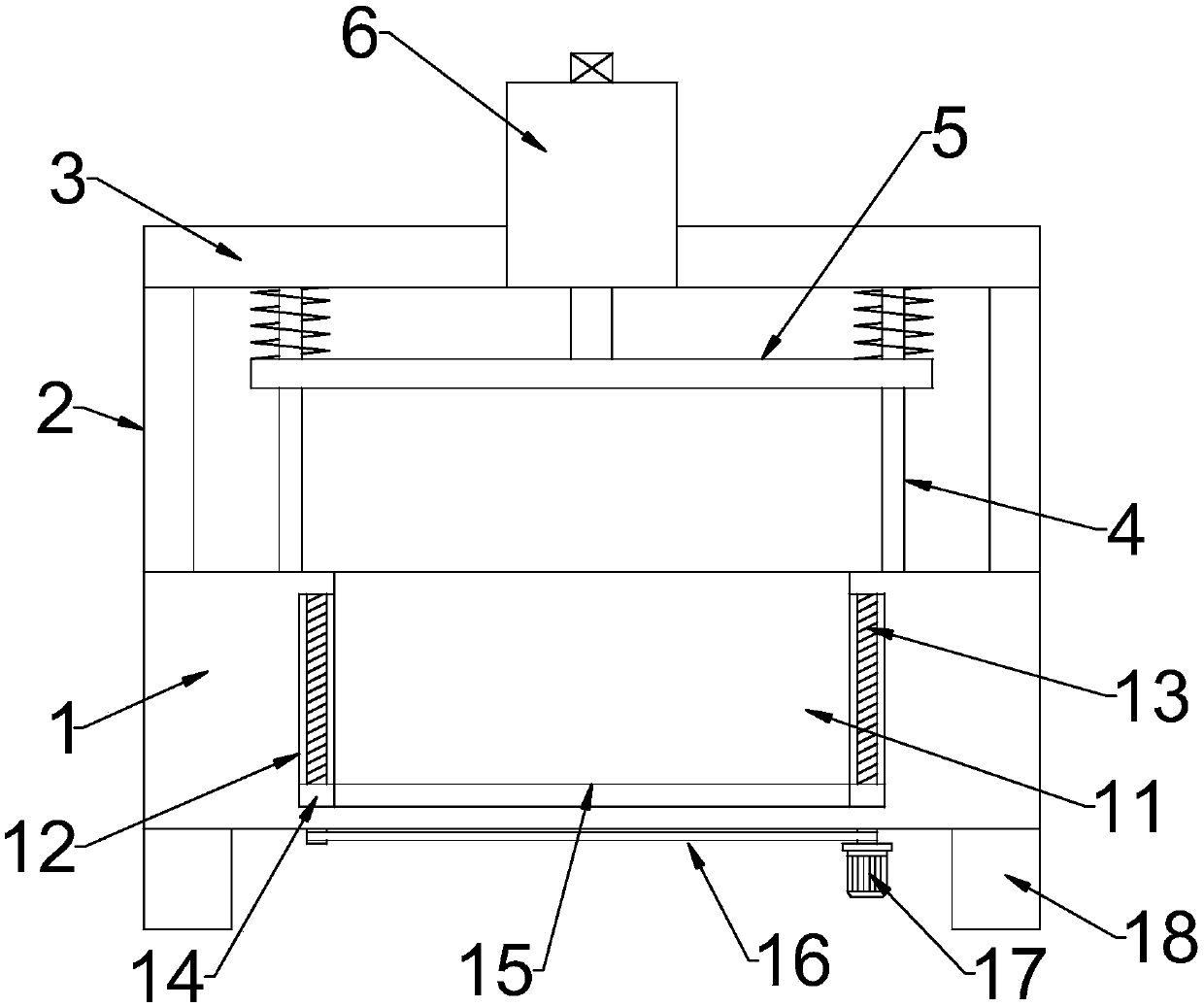

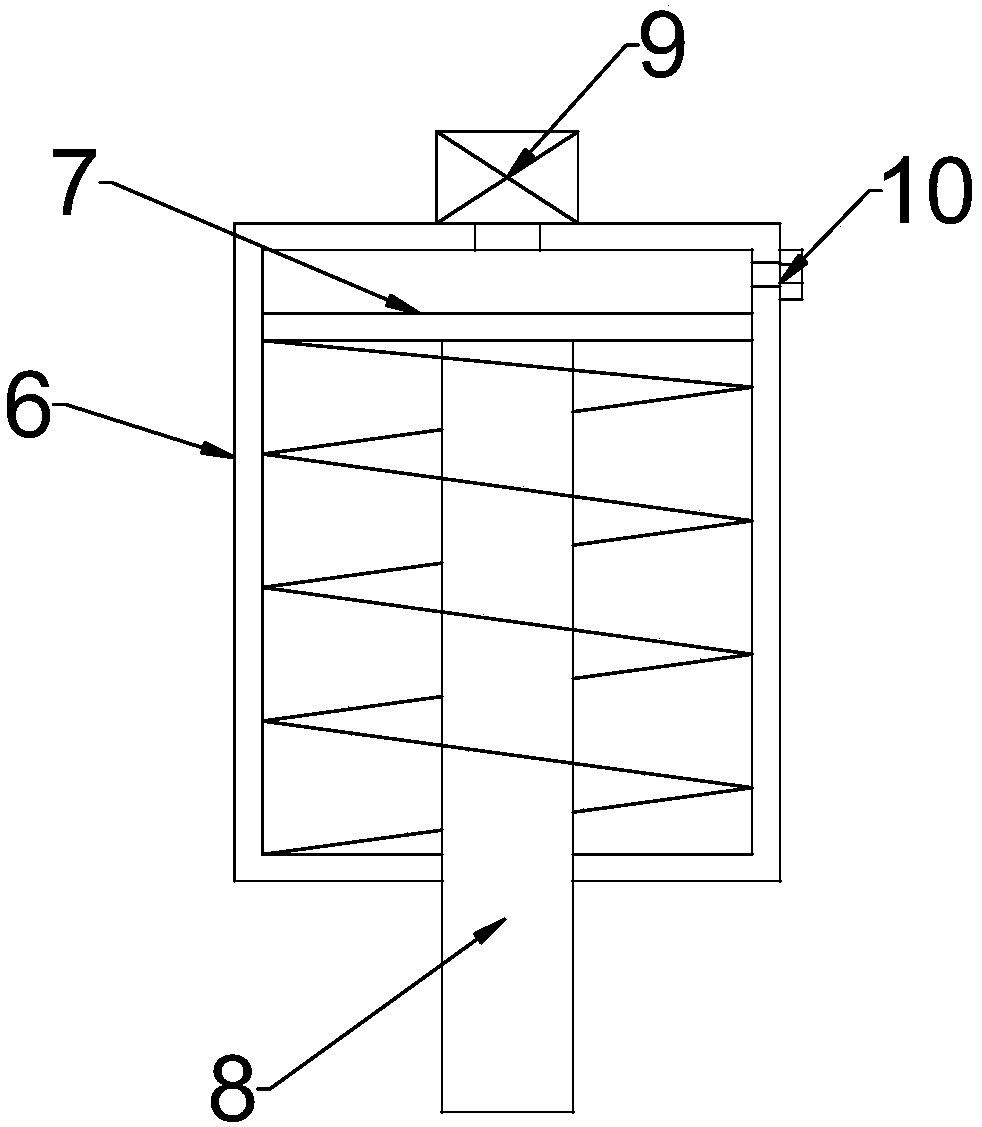

[0020] see Figure 1~2 , in an embodiment of the present invention, a pneumatic hot-press welding machine includes a supporting structure, a lifting structure, a driving structure 6 and a thermal welding head 5, and the supporting structure is symmetrically connected by a bracket 2 on both sides of the upper end of the base 1 to set a crossbeam 3 The middle part of the base 1 is embedded with a groove 11, and sliding grooves 12 are symmetrically embedded on both sides of the groove 11. A lifting structure is arranged between the sliding grooves 12, and a driving structure is arranged on the crossbeam 3. 6. A piston plate 7 is slidingly fitted in the driving structure 6, and the lower end of the piston plate 7 is elastically connected to the inner bottom of the driving structure 6 through a spring. The push rod 8 at the bottom of 6, the lower end of the push rod 8 is welded with a heat welding head 5, the two ends of the heat welding head 5 are symmetrically slid through and pr...

Embodiment 2

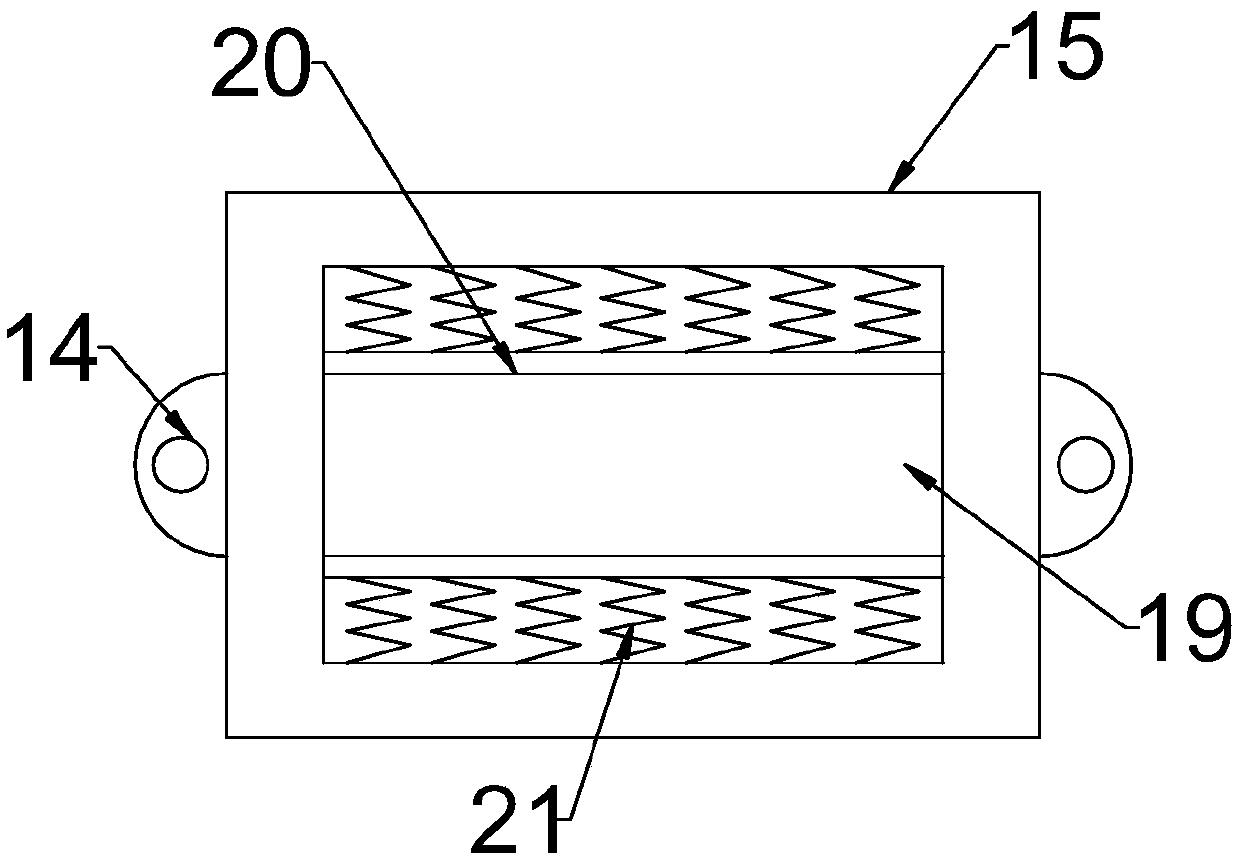

[0028] see image 3 , in the embodiment of the present invention, a pneumatic hot-press welding machine, on the basis of embodiment 1, the middle part of the upper end of the placement plate 15 is embedded with a placement groove 19, and the front and rear sides of the placement groove 19 are symmetrically passed through the clip The holding spring 21 is elastically connected with splints 20, and the opposite sides of the splints 20 on both sides are fitted with rubber pads.

[0029] In this way, it is convenient to assist in fixing and placing the mold, improve stability, facilitate alignment, and force more uniformly during processing, thereby ensuring the processing effect.

[0030] The working principle of the present invention is: when in use, the mold is placed between the splints 20 in the placement groove 19, which is convenient for auxiliary fixing and placement of the mold, improves stability, facilitates alignment, and the force is more uniform during the processing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com