Method for recovering vibration energy of rear axle of electric automobile

A technology of electric vehicles and vibration energy, which is applied to mechanisms that generate mechanical power, vehicle components, machines/engines, etc. It can solve the problems of generating vibration energy and the inability to effectively recover and utilize vibration energy, so as to increase power generation and ensure The service life and the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

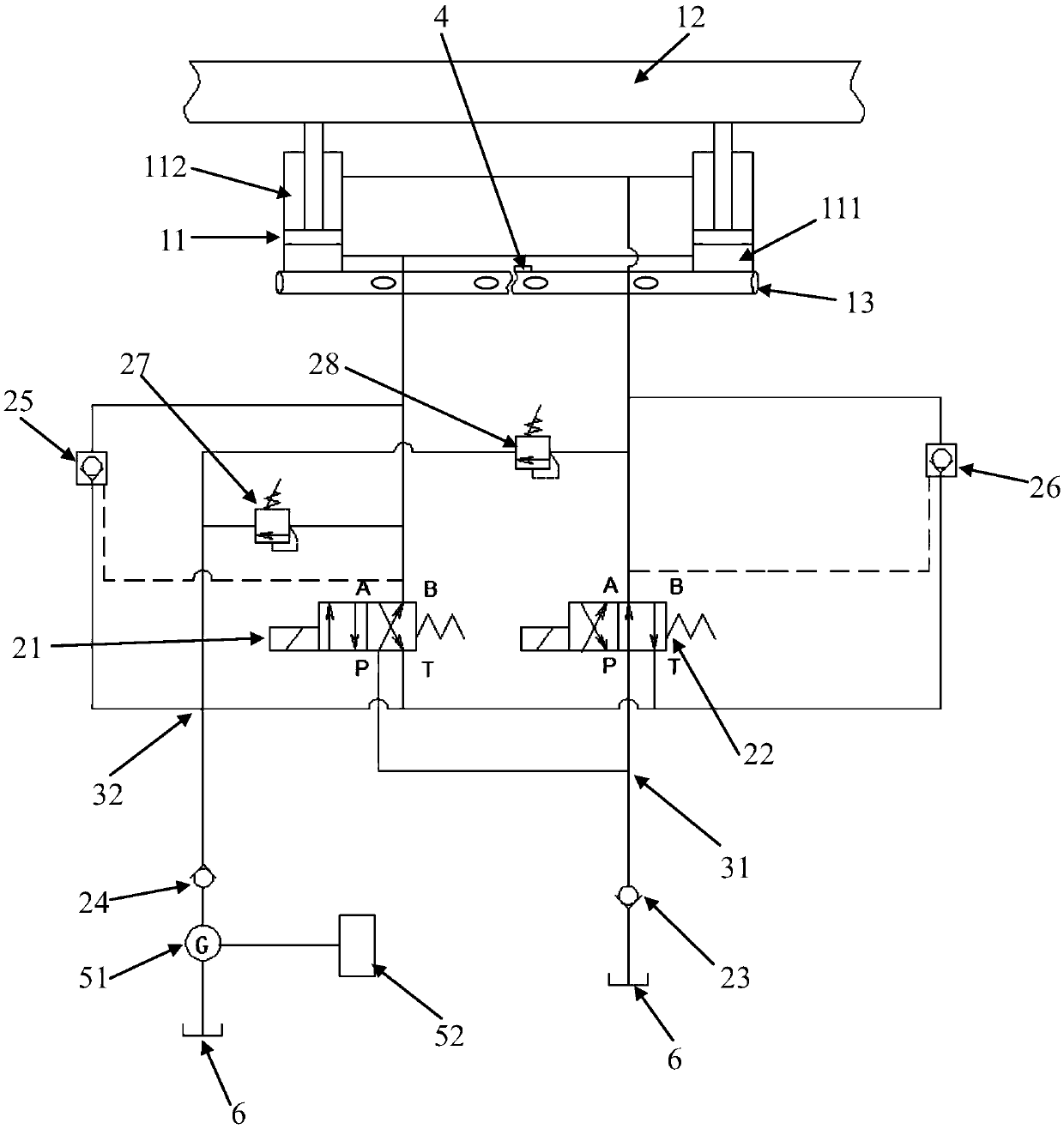

[0021] In order to facilitate the understanding of the present invention, the following will be described in conjunction with the accompanying drawings and embodiments.

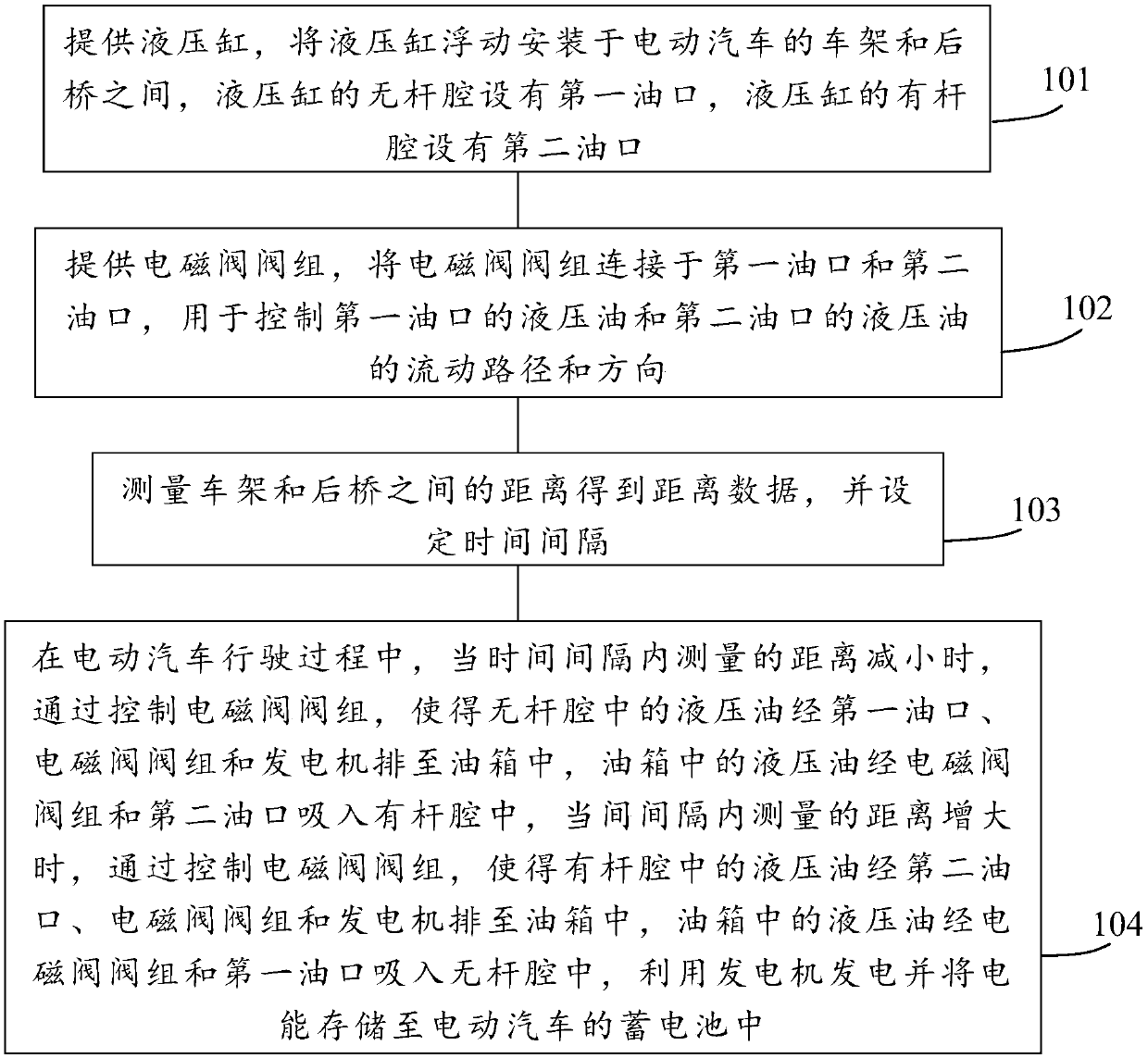

[0022] refer to figure 1 and figure 2 It can be seen that the present invention discloses a method for recovering the vibration energy of the rear axle of an electric vehicle, comprising the following steps:

[0023] Step 101: provide a hydraulic cylinder 11, and install the hydraulic cylinder 11 floatingly between the vehicle frame 12 and the rear axle 13 of the electric vehicle. The rodless cavity 111 of the hydraulic cylinder 11 is provided with a first oil port, and the rod cavity of the hydraulic cylinder 11 112 is provided with a second oil port;

[0024] Step 102: providing a solenoid valve group, connecting the solenoid valve group to the first oil port and the second oil port, for controlling the flow path and direction of the hydraulic oil in the first oil port and the hydraulic oil in the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com