Method for obtaining baicalein from scutellaria baicalensis root

A technology of Scutellaria baicalensis root and baicalein, applied in the field of obtaining baicalein from Scutellaria baicalensis root, can solve the problem of low extraction efficiency and achieve the effect of improving extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

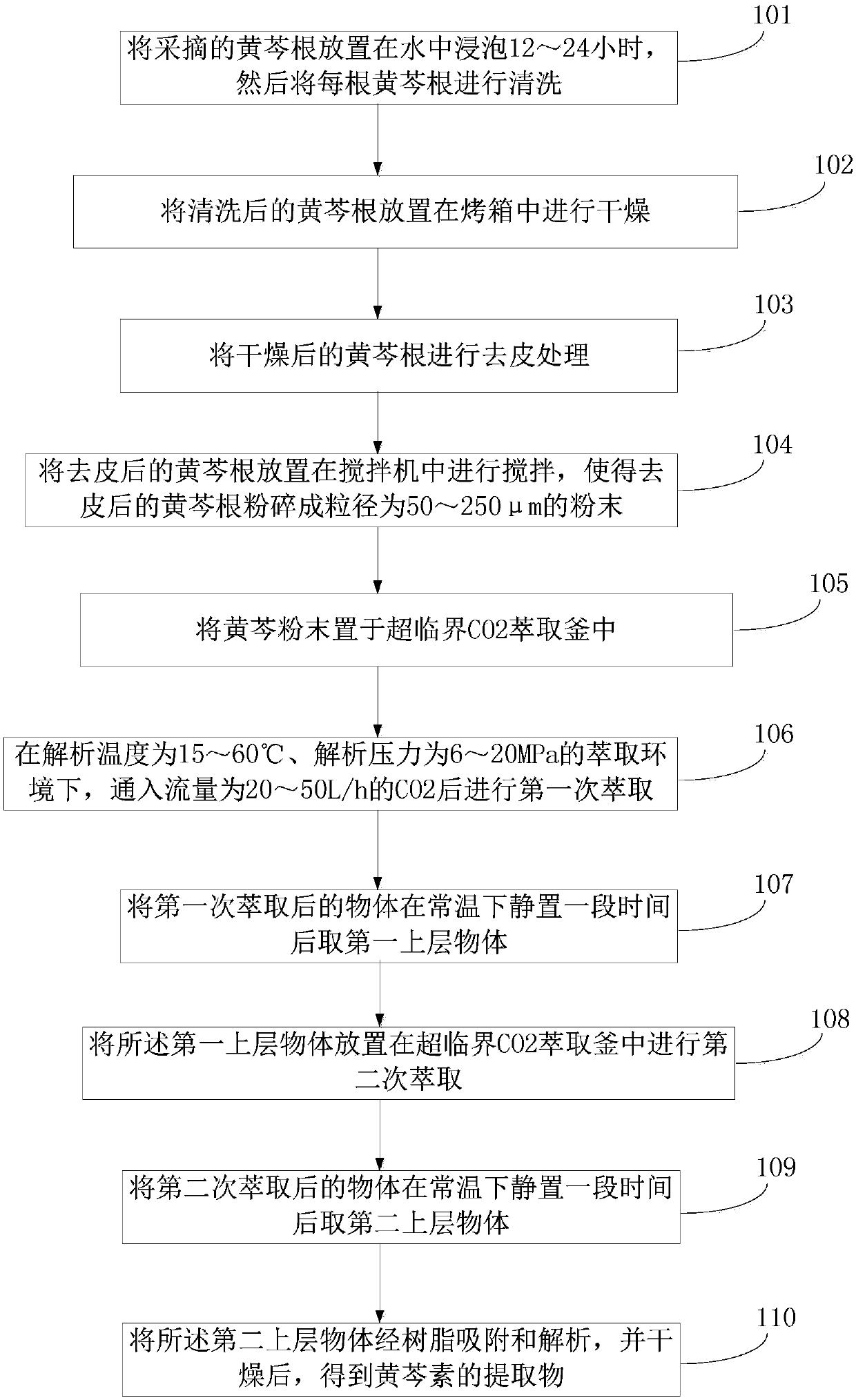

[0030] Step 1: Soak the picked Scutellaria baicalensis root in water for 12 hours, and then wash each Scutellaria baicalensis root.

[0031] Step 2: Place the cleaned Scutellaria baicalensis root in an oven for drying.

[0032] Step 3: Peel the dried Scutellaria baicalensis root.

[0033] Step 4: Place the peeled Scutellaria baicalensis root in a blender for stirring, so that the peeled Scutellaria baicalensis root is crushed into a powder with a particle size of 100 μm.

[0034] Step 5: Put the Scutellaria baicalensis powder in a supercritical CO2 extraction kettle, and conduct the first extraction after passing in CO2 with a flow rate of 35L / h in an extraction environment with a desorption temperature of 35°C and a desorption pressure of 8MPa.

[0035] Step 6: After the object extracted for the first time is allowed to stand at room temperature for a period of time, the first upper layer object is taken.

[0036] Step 7: placing the first upper layer object in a supercriti...

Embodiment 2

[0042] Step 1: Soak the picked Scutellaria baicalensis root in water for 24 hours, and then wash each Scutellaria baicalensis root.

[0043] Step 2: Place the cleaned Scutellaria baicalensis root in an oven for drying.

[0044] Step 3: Peel the dried Scutellaria baicalensis root.

[0045] Step 4: Place the peeled Scutellaria baicalensis root in a blender for stirring, so that the peeled Scutellaria baicalensis root is crushed into a powder with a particle size of 60 μm.

[0046] Step 5: Put the Scutellaria baicalensis powder in a supercritical CO2 extraction kettle, and conduct the first extraction after feeding CO2 with a flow rate of 40L / h in an extraction environment with a desorption temperature of 60°C and a desorption pressure of 12MPa.

[0047] Step 6: After the object extracted for the first time is allowed to stand at room temperature for a period of time, the first upper layer object is taken.

[0048] Step 7: placing the first upper layer object in a supercritical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com