Weather-resistant and low-temperature-resistant plastic packaging material

A technology of plastic packaging and low temperature resistance, which is applied in the field of plastic packaging materials, can solve the problems of polycarbonate not being resistant to low temperature and weathering, and achieve the effects of low temperature resistance and weather resistance, good weather resistance, and high low temperature impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

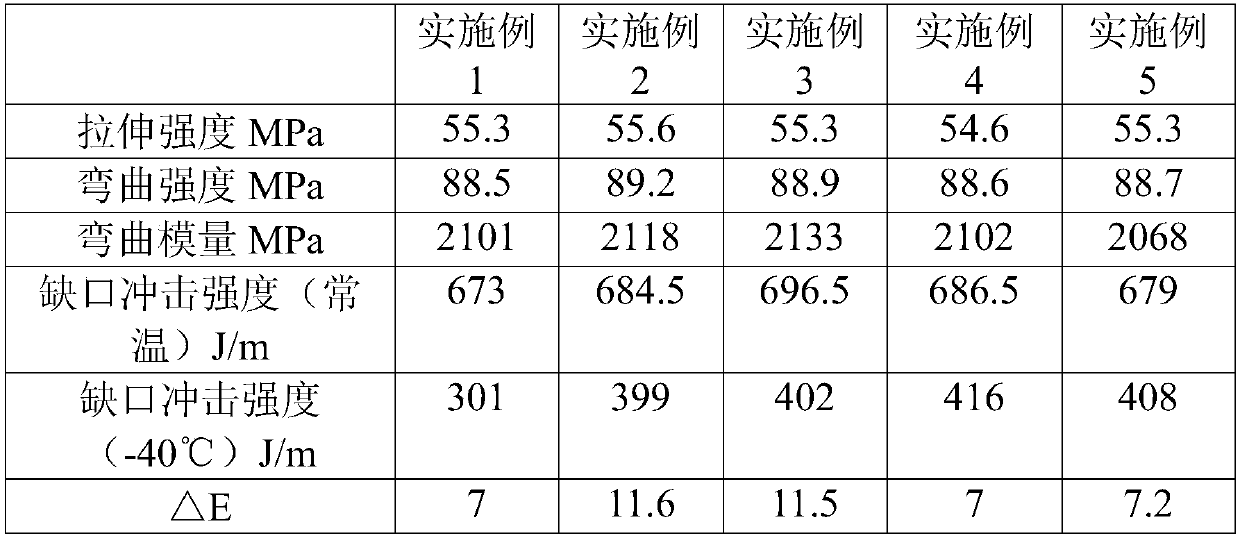

Examples

Embodiment 1

[0016] 100 parts of polycarbonate resin with a melt index of 10-15g / 10min, 10 parts of MBS toughening agent, 1.2 parts of benzotriazole UV absorber, 2 parts of magnesium hydroxide, 0.2 part of phosphite antioxidant, silicone 0.3 parts of lubricants.

Embodiment 2

[0018] 80 parts of polycarbonate resin with a melt index of 10-15g / 10min, 8 parts of silicon-acrylic toughening agent, 2 parts of MBS toughening agent, 1.1 parts of weather resistance agent, 1.5 parts of magnesium hydroxide, 0.2 parts of phosphite antioxidant , 0.2 parts of silicone lubricants.

Embodiment 3

[0020] Melt index 10-15g / 10min 98 parts of polycarbonate resin, 8 parts of silicone-acrylic toughening agent, 1.1 parts of weather resistance agent, 1.5 parts of magnesium hydroxide, 0.3 parts of phosphite antioxidant, 0.1 part of silicone lubricant share.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com