A kind of polishable flame-retardant automotive structural adhesive composition and preparation method thereof

A technology of automobile structure and composition, which is applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve the problems of poor grinding performance, poor flame retardancy, long curing time, etc., to improve initial tack, solve The effect of low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

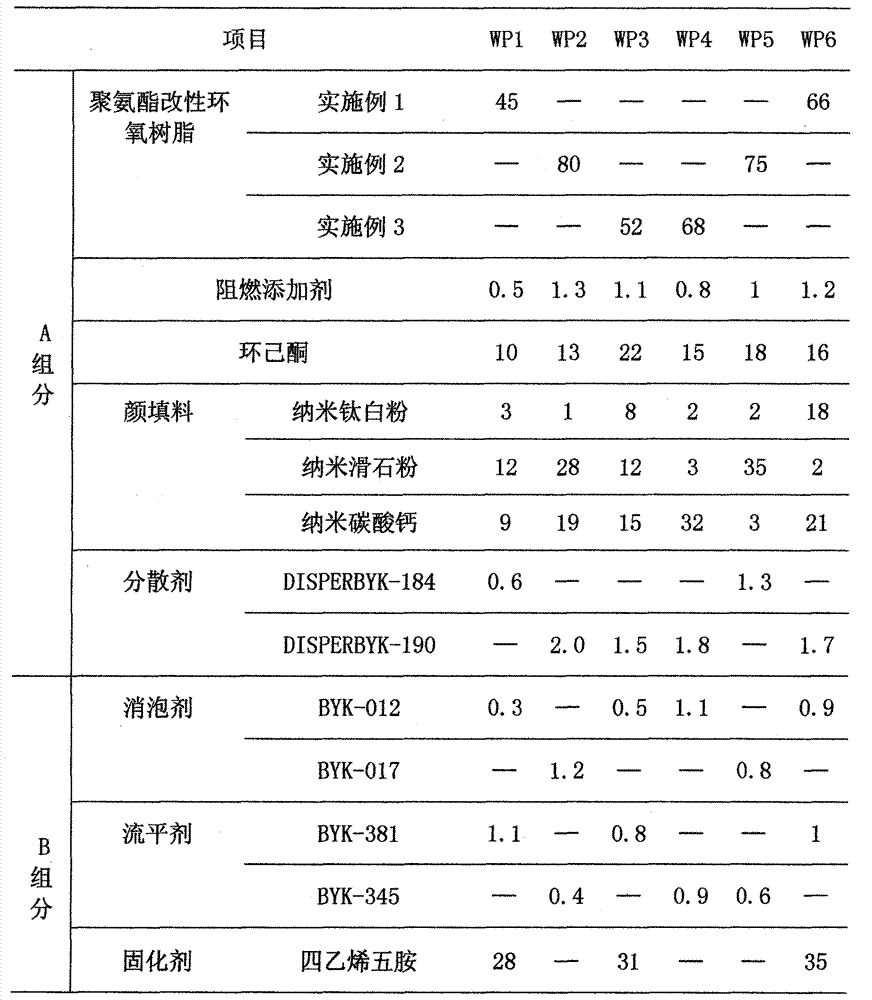

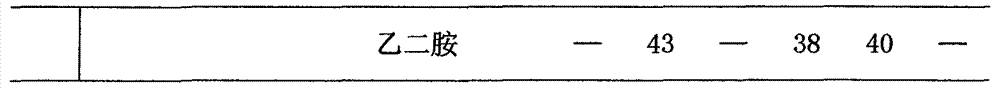

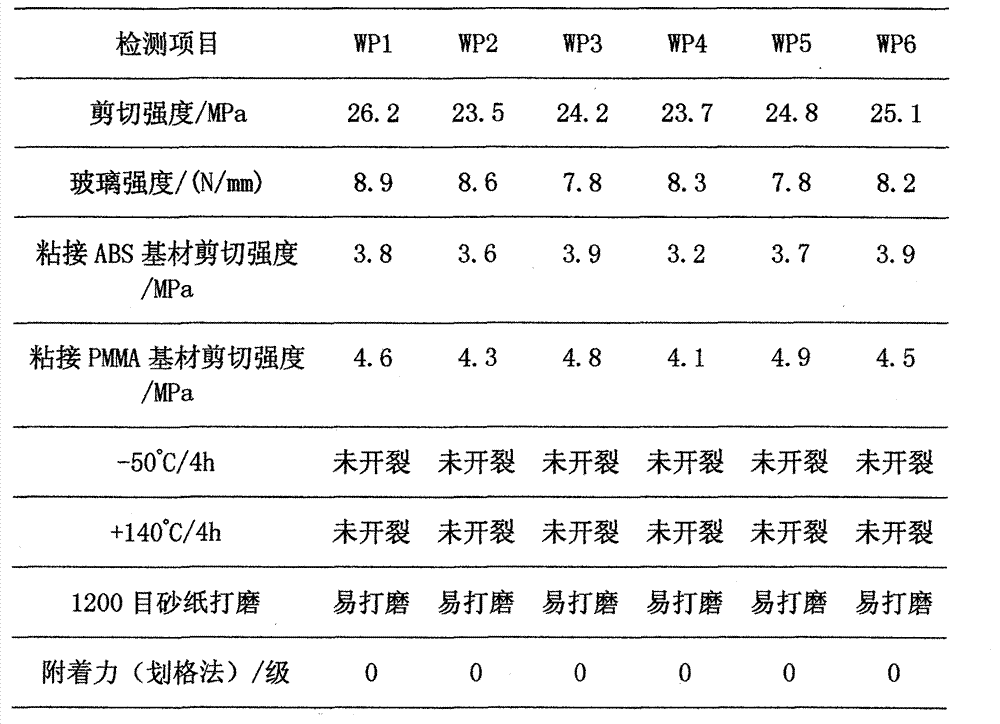

Examples

Embodiment 1

[0028] Under nitrogen protection, 20g of epoxy resin E44, 3g of dihydroxypolysiloxane, 30g of hexamethylene diisocyanate, and 100ml of butanone were reacted for 2.5 hours at 80°C to obtain the first intermediate product;

[0029] Add 1.5 g of rosin resin and 0.0003 g of dibutyltin dilaurate to the first intermediate product, and continue the reaction at 85° C. for 2 h under the protection of nitrogen to obtain the second intermediate product.

[0030] Under nitrogen protection, 9.9 g of butanediol was added to the second intermediate product, and the temperature was raised to 90° C. for 1.5 h. After the reaction was terminated, butanone was removed under reduced pressure to obtain a polyurethane-modified epoxy resin.

Embodiment 2

[0032] Under nitrogen protection, 35g of epoxy resin E51, 2.3g of dihydroxypolysiloxane, 85g of isophorone diisocyanate, and 150ml of butanone were reacted for 4 hours at 80°C to obtain the first intermediate product;

[0033] Add 2.1 g of rosin resin and 0.0004 g of dibutyltin dilaurate to the first intermediate product, and continue the reaction at 85° C. for 2 h under the protection of nitrogen to obtain the second intermediate product.

[0034] Under nitrogen protection, 19.7 g of butanediol was added to the second intermediate product, and the temperature was raised to 90° C. for 1.5 h. After the reaction was terminated, butanone was removed under reduced pressure to obtain a polyurethane-modified epoxy resin.

Embodiment 3

[0036] Under the protection of nitrogen, 28g of epoxy resin E12, 3g of dihydroxypolysiloxane, 12g of hexamethylene diisocyanate, and 200ml of butanone were reacted for 3 hours at 80°C to obtain the first intermediate product;

[0037] Add 0.8 g of rosin resin and 0.0006 g of dibutyltin dilaurate to the first intermediate product, and continue the reaction at 85° C. for 2 h under the protection of nitrogen to obtain the second intermediate product.

[0038] Under nitrogen protection, 7.4 g of butanediol was added to the second intermediate product, and the temperature was raised to 90° C. for 1.5 h. After the reaction was terminated, butanone was removed under reduced pressure to obtain a polyurethane-modified epoxy resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com