Manufacturing method of mirror oriented silicon steel

A manufacturing method and technology for oriented silicon steel, applied in the field of steelmaking, can solve the problems of affecting the stability of secondary recrystallization and the effect of steel purification, uneven coating of annealing separators, complex coating processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

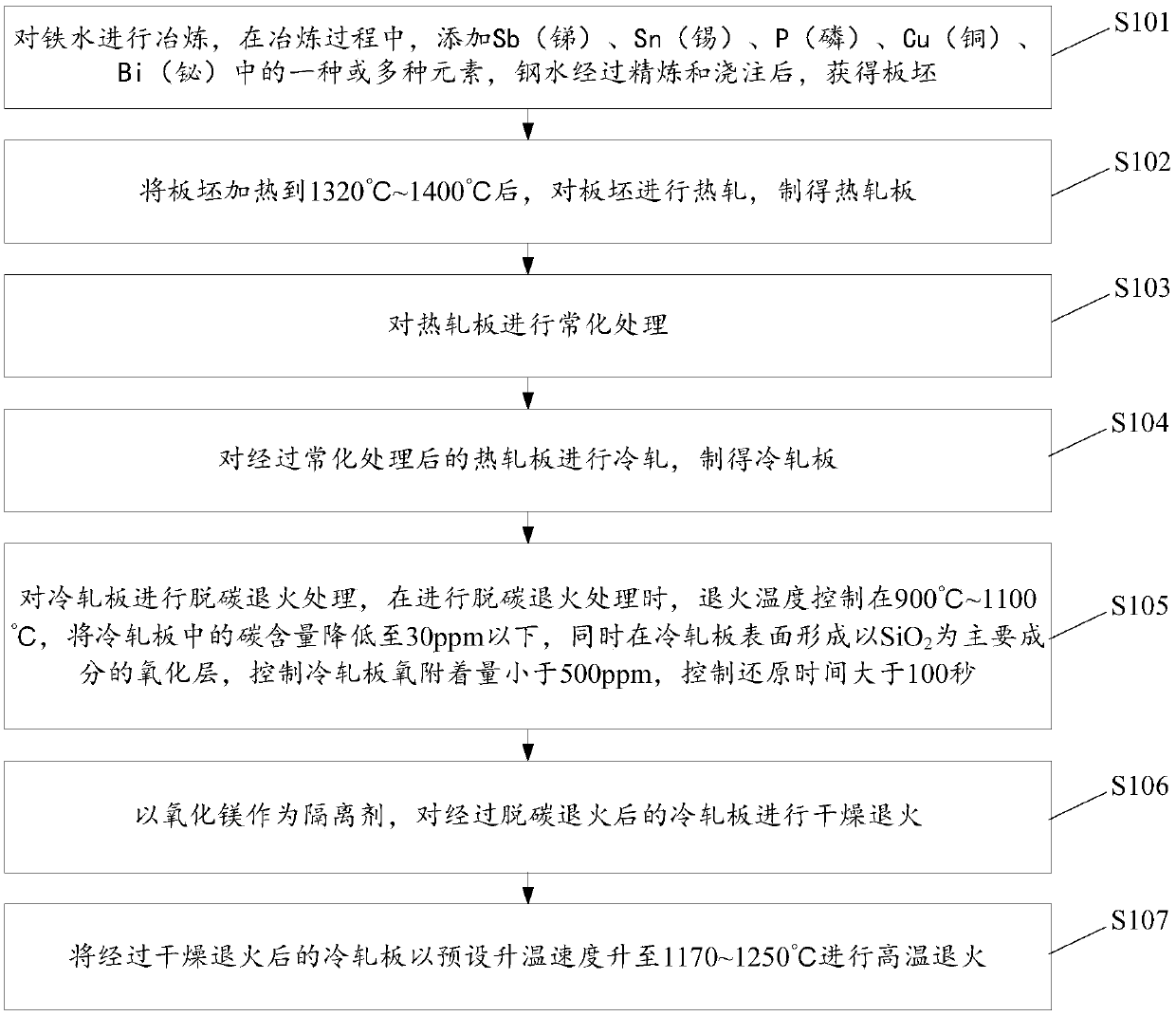

[0034] Such as figure 1 As shown, this embodiment provides a method for manufacturing mirror-oriented silicon steel, including:

[0035] Step S101: Smelting molten iron, adding one or more elements of Sb (antimony), Sn (tin), P (phosphorus), Cu (copper), and Bi (bismuth) during the smelting process, and the molten steel is refined And after pouring, a slab is obtained.

[0036] In the specific implementation process, when the molten iron is smelted, the molten iron can be put into a converter or an electric furnace for smelting, and the molten iron can be smelted through a converter or an electric furnace.

[0037] In the specific implementation process, when the slab is hot-rolled, the temperature at the end of rough rolling is controlled to not be lower than 1200°C (for example: 1200°C, 1250°C, 1300°C, etc.), and the temperature at the start of finish rolling is controlled to not be lower than 1000°C (eg: 1000°C, 1050°C, 1100°C, etc.).

[0038] Step S102: After the slab i...

Embodiment 2

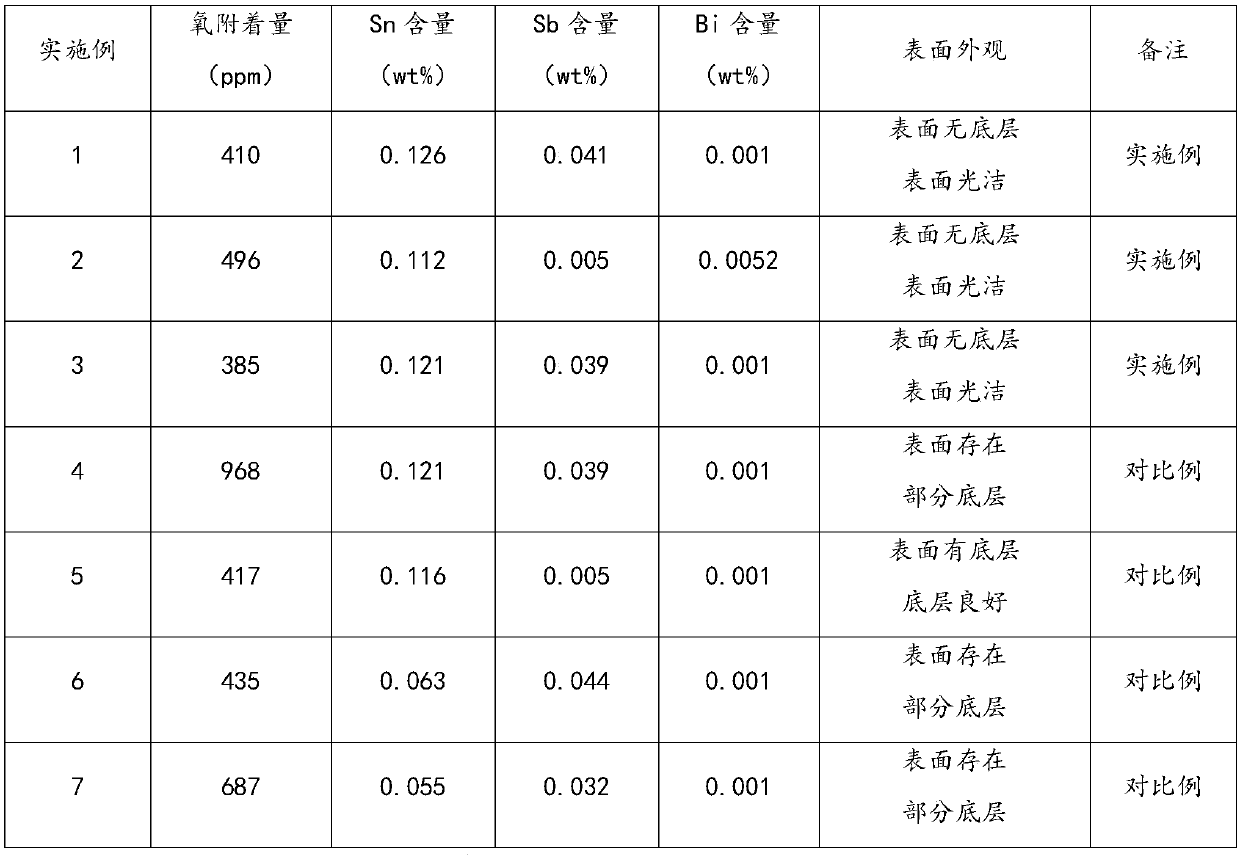

[0055] Oriented silicon steel is smelted with a converter. The chemical composition (wt%) of the slab is: 0.072% C, 3.12% Si, 0.077% Mn, 0.022% S, 0.008% N, 0.145% Sn, 0.035% Cu, 0.0305% of Als, 0.025% of Cr, 0.016% of P, 0.022% of Sb, 0.0048% of Bi, etc., and the remaining components are Fe and unavoidable impurities.

[0056] After the slab is heated at 1370°C, it is hot-rolled into a hot-rolled sheet with a thickness of 2.3mm. The hot-rolled sheet was annealed at 1125°C for 1.5 minutes, then pickled and cold-rolled to its final thickness. The cold-rolled sheet was decarburized and annealed at 840°C. . Without nitriding treatment, it is directly coated with conventional magnesia spacer and dried, then enters the ring furnace for high temperature annealing. The temperature was raised to 1190°C at a heating rate of 17°C / h and kept at 1190°C for 25 hours, and the hydrogen content in the protective atmosphere was 75%. After leaving the ring furnace, carry out stretching and l...

Embodiment 3

[0062] Oriented silicon steel is smelted with a converter. The composition and weight percentage of the slab are: C: 0.06% to 0.10%, Si: 2.9% to 3.3%, Mn: 0.05% to 0.10%, P: 0.01 to 0.055%, S: 0.01 ~0.03%, Als: 0.02%~0.035%, N: 0.007%~0.010%, Cr: 0.02%~0.4%, Sb: 0.005%~0.065%, Sn: 0.02%~0.2%, Cu: 0.03%~0.10 %, Bi: 0.001% to 0.03%, etc., and the rest are Fe and unavoidable impurities.

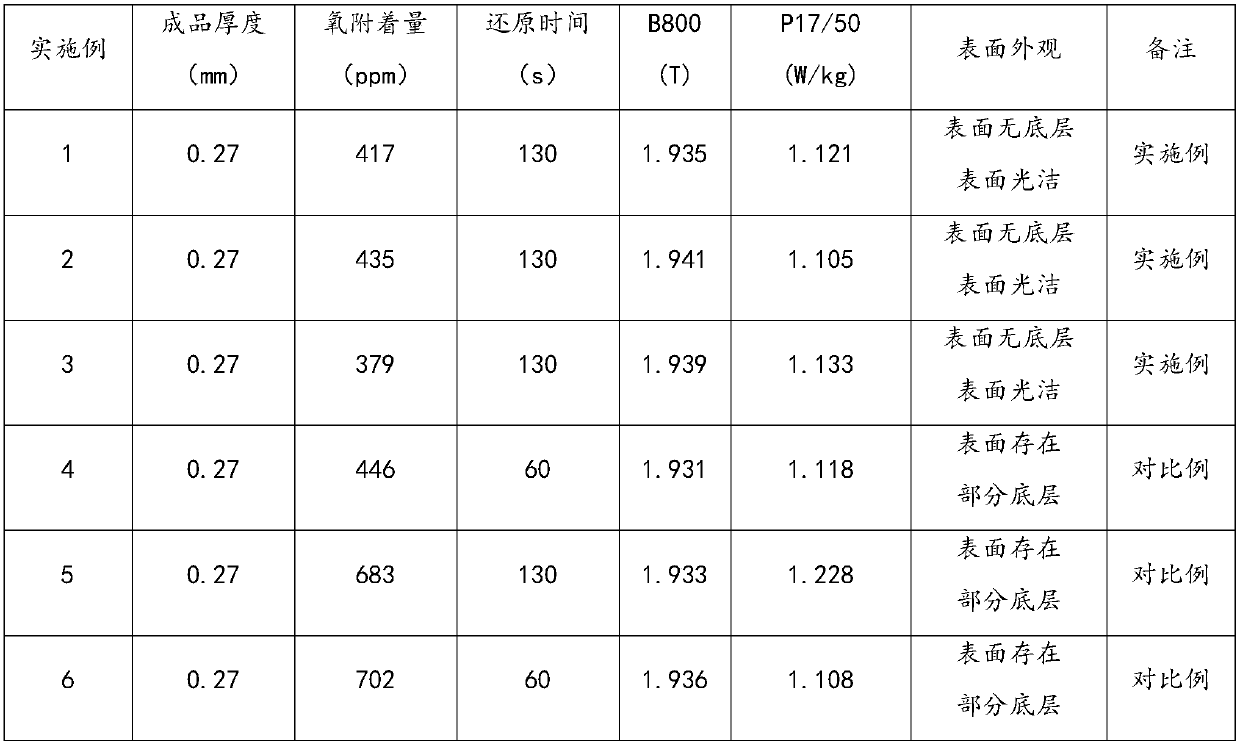

[0063] After the slab is heated at 1370°C, it is hot-rolled into a hot-rolled sheet with a thickness of 2.3 mm. The hot-rolled sheet was annealed at 1125°C for 1.5 minutes, then pickled and cold-rolled to the final thickness. The cold-rolled sheet is decarburized and annealed at 840°C, and the reduction time after decarburization is 130 seconds. It is directly coated with conventional magnesium oxide release agent without nitriding treatment, and then enters the ring furnace for high-temperature annealing. The temperature was raised to 1190°C at a heating rate of 17°C / h and kept at 1190°C for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com