Hot-rolled TRIP steel with tensile strength being 900 MPa level and preparation method thereof

A technology for tensile strength and hot-rolled plates, applied in the field of hot-rolled TRIP steel with a tensile strength of 900MPa and its preparation, can solve problems such as the limitation of high-strength steel strength levels, and achieve good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The second aspect of the present invention provides a method for preparing the above-mentioned hot-rolled TRIP steel with a tensile strength of 900MPa, the steps comprising:

[0045] S1, obtaining the molten steel with the above composition and then casting to obtain a slab;

[0046] S2, heat-treating the obtained cast slab under nitrogen protection, the heating temperature of the heat treatment is 1230-1270°C, and the holding time is 1 hour;

[0047] S3. The hot-rolled plate is obtained by hot-rolling by two-stage rolling process, the starting rolling temperature is 1120-1170°C, and the finishing rolling temperature is 850-930°C;

[0048] S4. Cool the hot-rolled sheet at a cooling rate of 20-30°C / s, cool it to 570-630°C, put it into a furnace (furnace temperature is 200-400°C) and keep it warm for 25-35 minutes, then cool it with the furnace to obtain a finished product, hot-rolled After 7 passes of rolling, the thickness range of the plate is controlled at 4-6mm; the...

Embodiment 1

[0053] This embodiment provides a method for preparing hot-rolled TRIP steel with a tensile strength of 900 MPa. The steps include:

[0054] After obtaining the molten steel, cast it to obtain a slab; the chemical composition of the molten steel is: by mass percentage, C: 0.11%, Si: 0:060%, Mn: 5.03%, P: 0.005%, S: 0.003%, Al: 1.82%, Nb: 0.036%, V: 0.060%, and the rest are Fe and unavoidable impurities.

[0055] The obtained slab was heated under the protection of nitrogen, the heating temperature was 1238° C., and the holding time was 1 hour.

[0056] The hot-rolled plate is hot-rolled by two-stage rolling process, the rolling start temperature is 1150°C, the thickness specification variation range of the hot-rolled plate is controlled at 4-5 mm after 7 passes of rolling, and the rolling termination temperature is controlled as 895°C. The hot-rolled plate is cooled at a cooling rate of 25°C / s, cooled to 600°C by laminar flow, put into the furnace (furnace temperature is 330...

Embodiment 2- Embodiment 6

[0060] Embodiments 2-6 all provide a method for preparing hot-rolled TRIP steel with a tensile strength of 900 MPa. The preparation method is basically the same as that of Example 1, the difference lies in the chemical composition of molten steel and some preparation process parameters. Specifically, Example 2 The chemical composition of the slab used in -6 is shown in Table 1, the control requirements of the preparation process parameters are shown in Table 2, and the preparation process of the other unmentioned parts is the same as that of Example 1.

[0061] Each embodiment of table 1 molten steel chemical composition mass percent (%)

[0062] serial number

[0063] Each embodiment process parameter of table 2

[0064] serial number

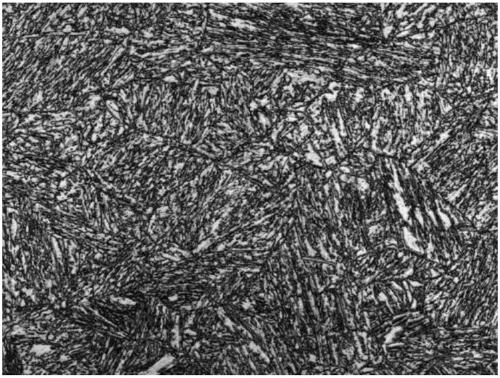

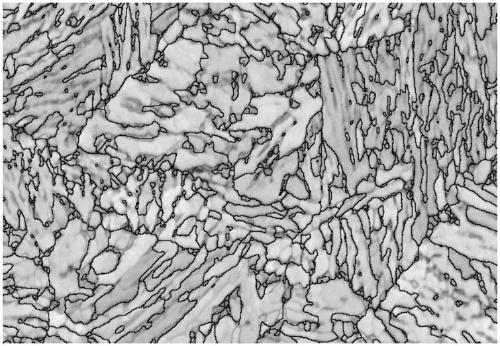

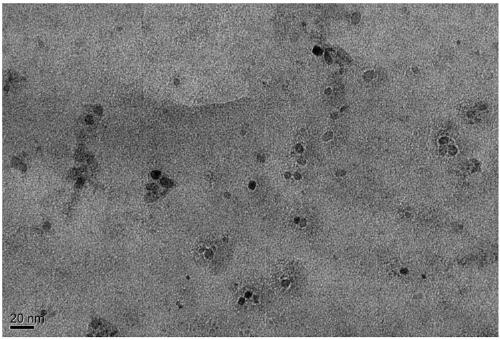

[0065] The microstructure of the product obtained in Examples 2-6 is basically consistent with Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com