Staggered tooth impeller and extractor hood

An impeller, staggered teeth technology, applied in the field of air purification equipment, can solve the problem of difficult to obtain noise reduction air purification equipment, increase the gap and other problems, to achieve the effect of weakening the strength, increasing the air volume and reducing the noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

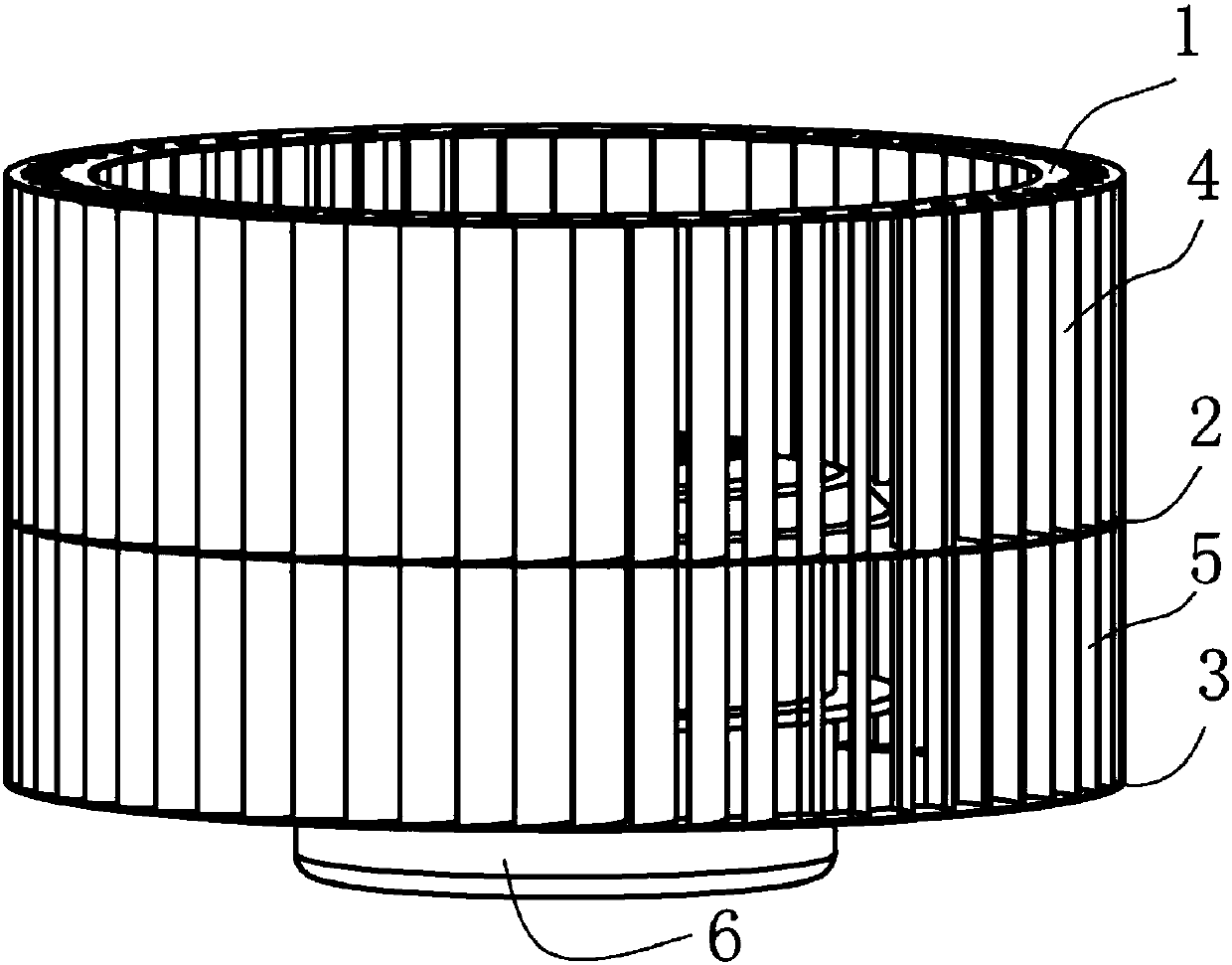

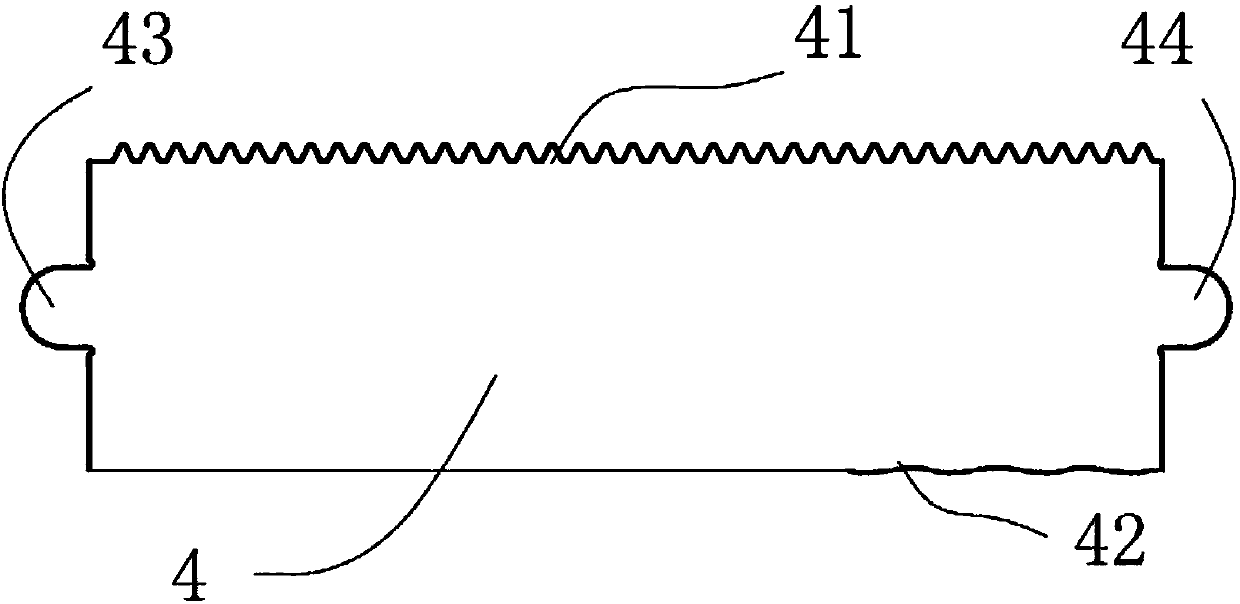

[0058] like figure 1 , figure 2 As shown, the staggered-toothed impeller in this embodiment includes an upper disk 1, a middle disk 2 and a lower disk 3 arranged coaxially, and a plurality of first blades 4 connected to the upper disk 1 and the middle disk 2 at both ends. A plurality of second vanes 5 connected to the middle plate 2 and the lower plate 3 respectively. In this embodiment, the plurality of leading edges 41 of the first blades are configured in a zigzag shape, and the side of the trailing edge 42 of the first blades near the central disk 2 is configured in a wave shape. Through the above design, the vortex in the flow channel of the staggered-toothed impeller can be destroyed, thereby reducing the generation and shedding of the vortex, and achieving the purpose of reducing noise. The design of the wavy trailing edge makes the air flow more smoothly in the impeller channel, which can not only increase the air volume, but also reduce noise. The two ends of the ...

Embodiment 2

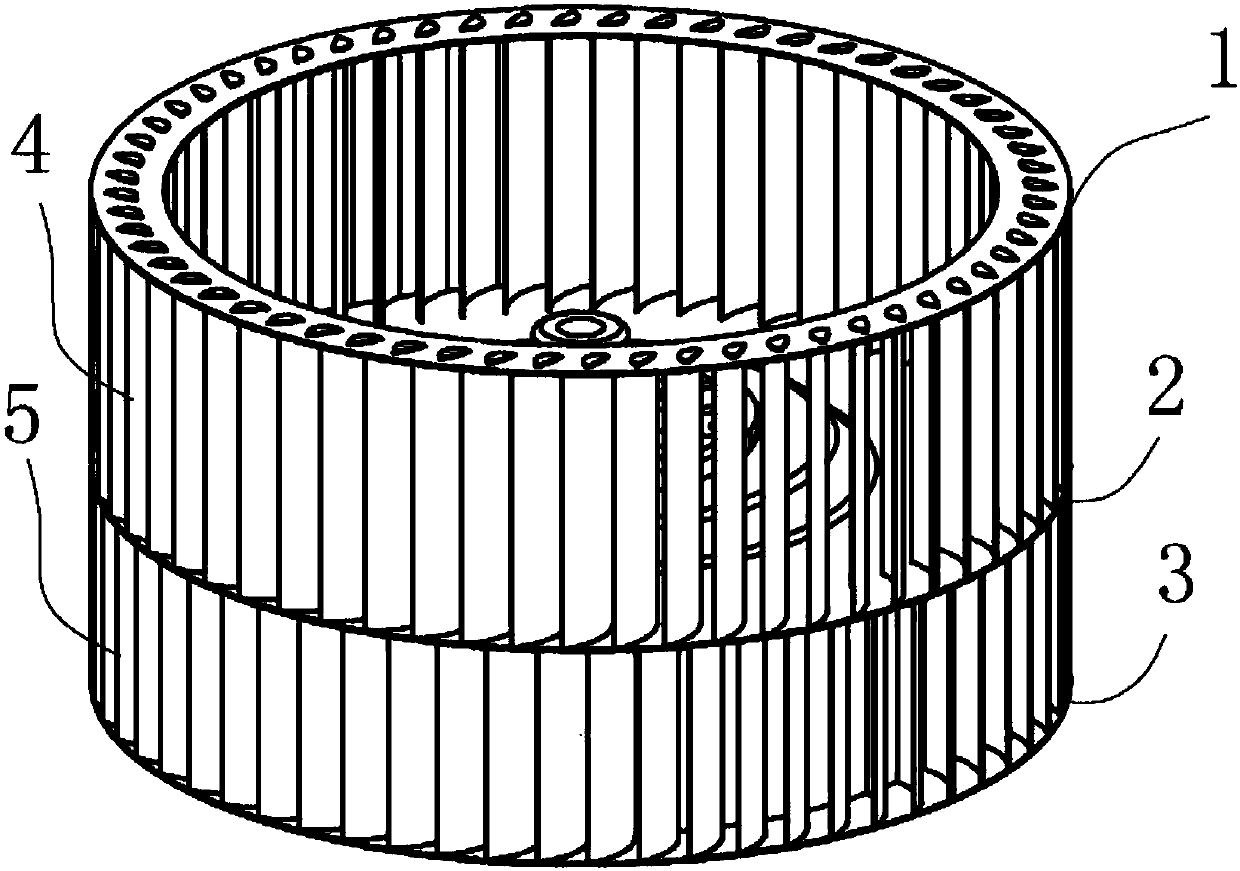

[0061] like image 3 , Figure 4 As shown, the difference between the staggered-toothed impeller in this embodiment and the above-mentioned embodiments is that: the trailing edges 52 of the second blades 5 of the plurality of second blades 5 are all set in a wave shape. Through the above design, the vortex in the channel of the staggered-toothed impeller can be more effectively destroyed, thereby reducing the generation of vortex. The inventor found through experiments that the structural design of the second blade can increase the air volume by 0.6m 3 / min, the noise drops by 0.5dB(A). It can be seen that the effect of this structure on increasing air volume and reducing noise is very obvious.

[0062] Moreover, the first blade 4 and the second blade 5 of the staggered-toothed impeller in this embodiment are arranged in a staggered position. That is, the first blades 4 and the second blades 5 are arranged in a staggered manner relative to the central disk 2 . The disloca...

Embodiment 3

[0064] The difference between the staggered-toothed impeller in this embodiment and the above-mentioned embodiment is that the arrangement angles of the first blade and the second blade are different; The time of vortex generation is divided into multiple periods to avoid the violent vibration caused by the superposition of vortex, thereby avoiding the generation of noise. After a lot of experiments, the inventor found that when the first blade and the second blade are staggered clockwise by 2-6°, a better noise reduction effect can be obtained; further, when the angle is set to 3°, the noise reduction effect optimal.

[0065] In this embodiment, the first vane and the second vane are also designed to have different sizes in the length direction. When the size ratio of the first blade to the second blade in the length direction is 4:3, the interaction between the blade size ratio and the blade deflection angle can obtain a better noise reduction effect, and the air volume ban...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com