Floor heating pipe for building floor heating

A floor heating pipe and floor heating technology, applied in the direction of pipes, rigid pipes, pipe supports, etc., can solve the problems of smooth surface of pipes, inconvenient installation, unsatisfactory anti-corrosion performance, and reduced life of floor heating pipes, so as to achieve short-term and long-term strength enhancement and reasonable design , The effect of speeding up the temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below in conjunction with specific embodiments.

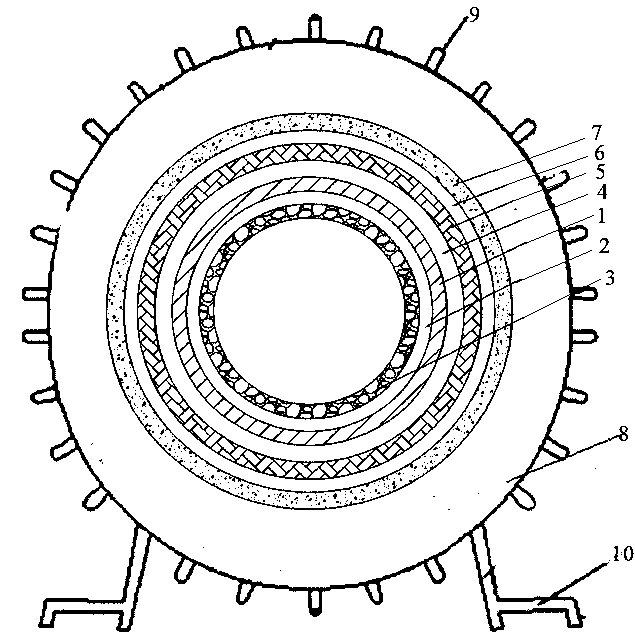

[0011] as attached figure 1 As shown, the inner side of the pipe body 1 of this embodiment is provided with a high temperature resistant heat conduction strengthening layer 2, and the inner side of the high temperature resistant heat conduction strengthening layer 2 is provided with a nano antibacterial layer 3; the outer side of the pipe body 1 is provided with an aluminum layer 5, which is connected with the pipe A hot-sol layer 4 is provided between the body 1, an anti-oxygen layer 6 is provided on the outer side of the aluminum layer 5, a protective layer 7 is provided on the outer side of the oxygen-proof layer 6, an anti-corrosion layer 8 is provided on the outer side of the protective layer 7, and an anti-corrosion layer 8 is provided on the outer wall of the anti-corrosion layer 8. A plurality of bosses 9 are arranged along the circumference, and the bosse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com