Fly ash conveying system for garbage incinerator

A waste incinerator and conveying system technology, which is applied in the field of waste incineration power plant furnace system, can solve the problems of waste incineration power generation system not running normally, high equipment operating costs, and small gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

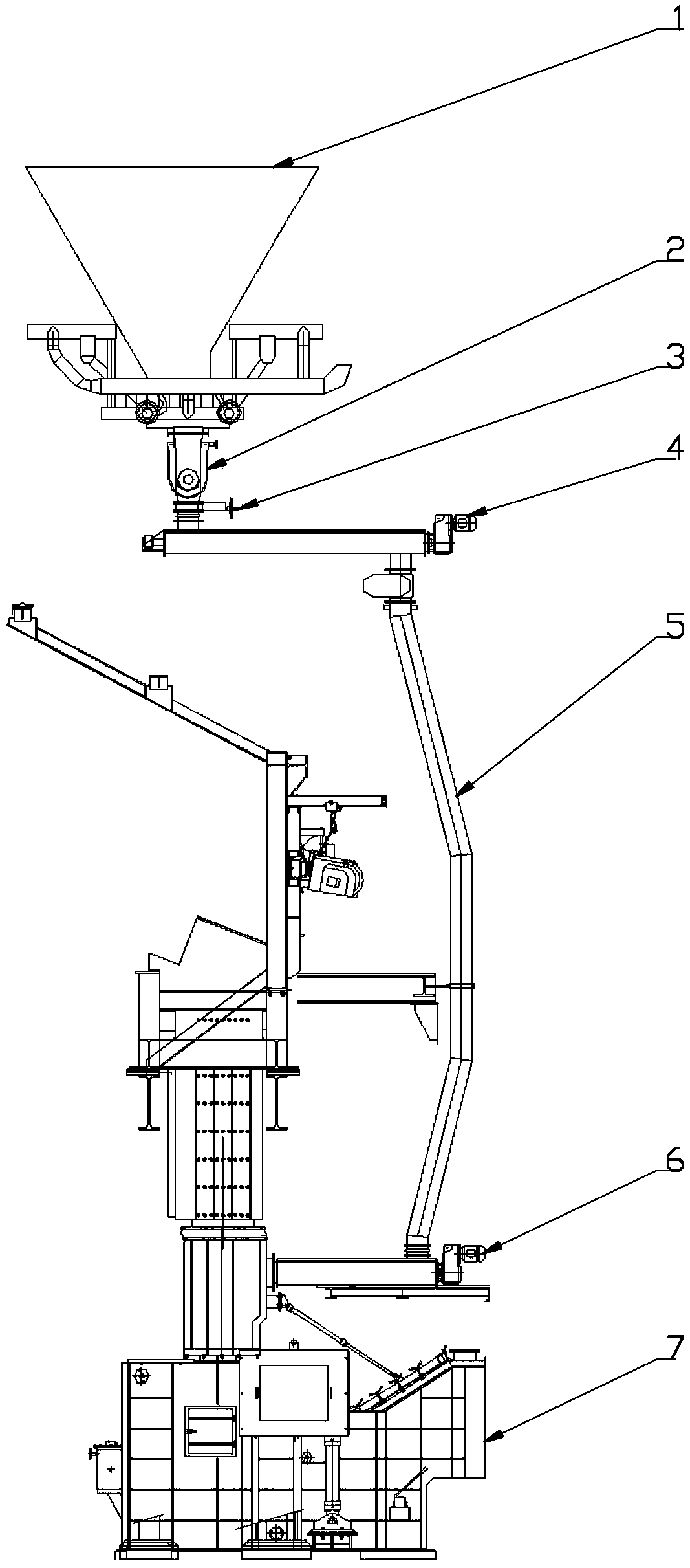

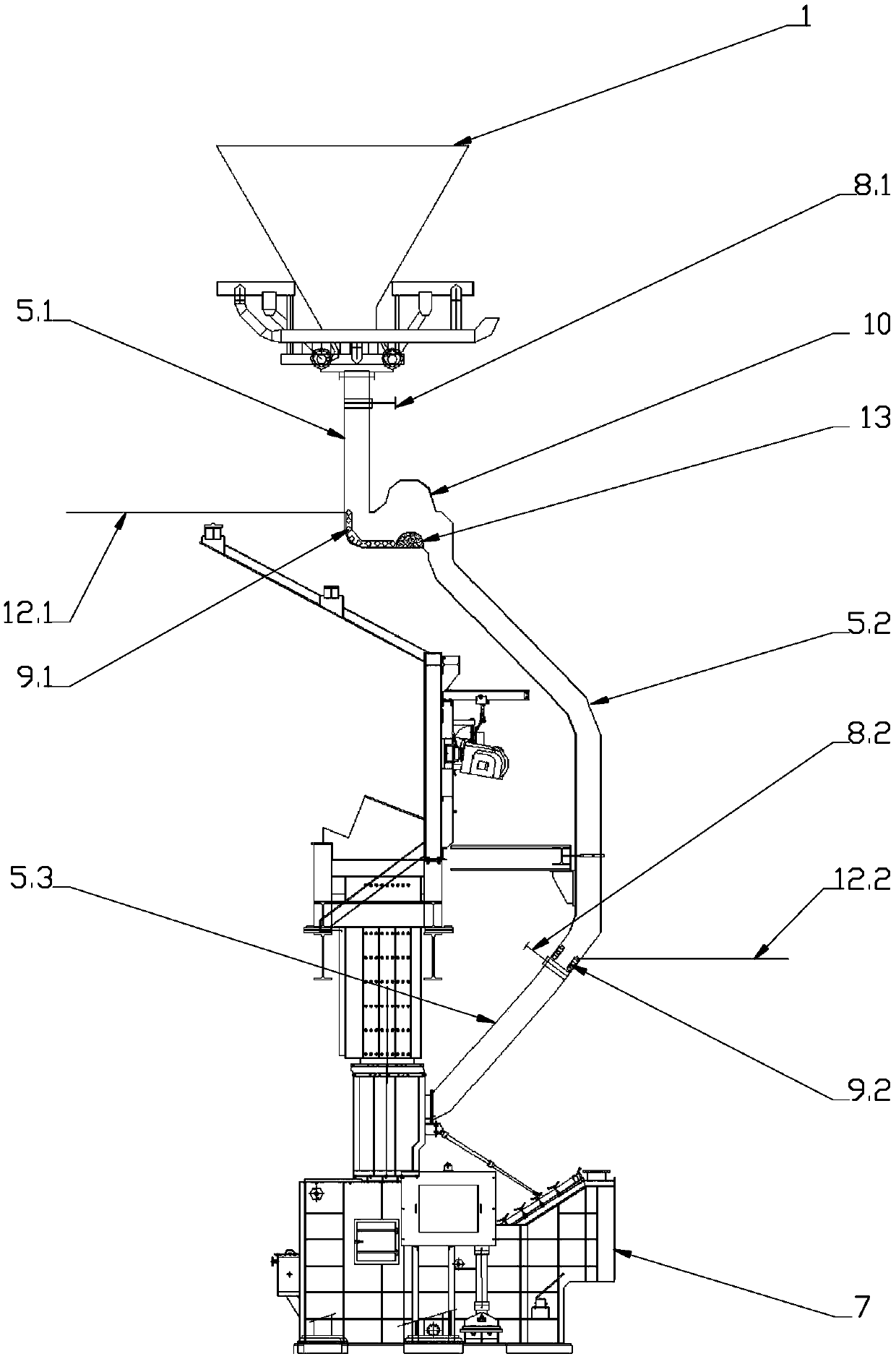

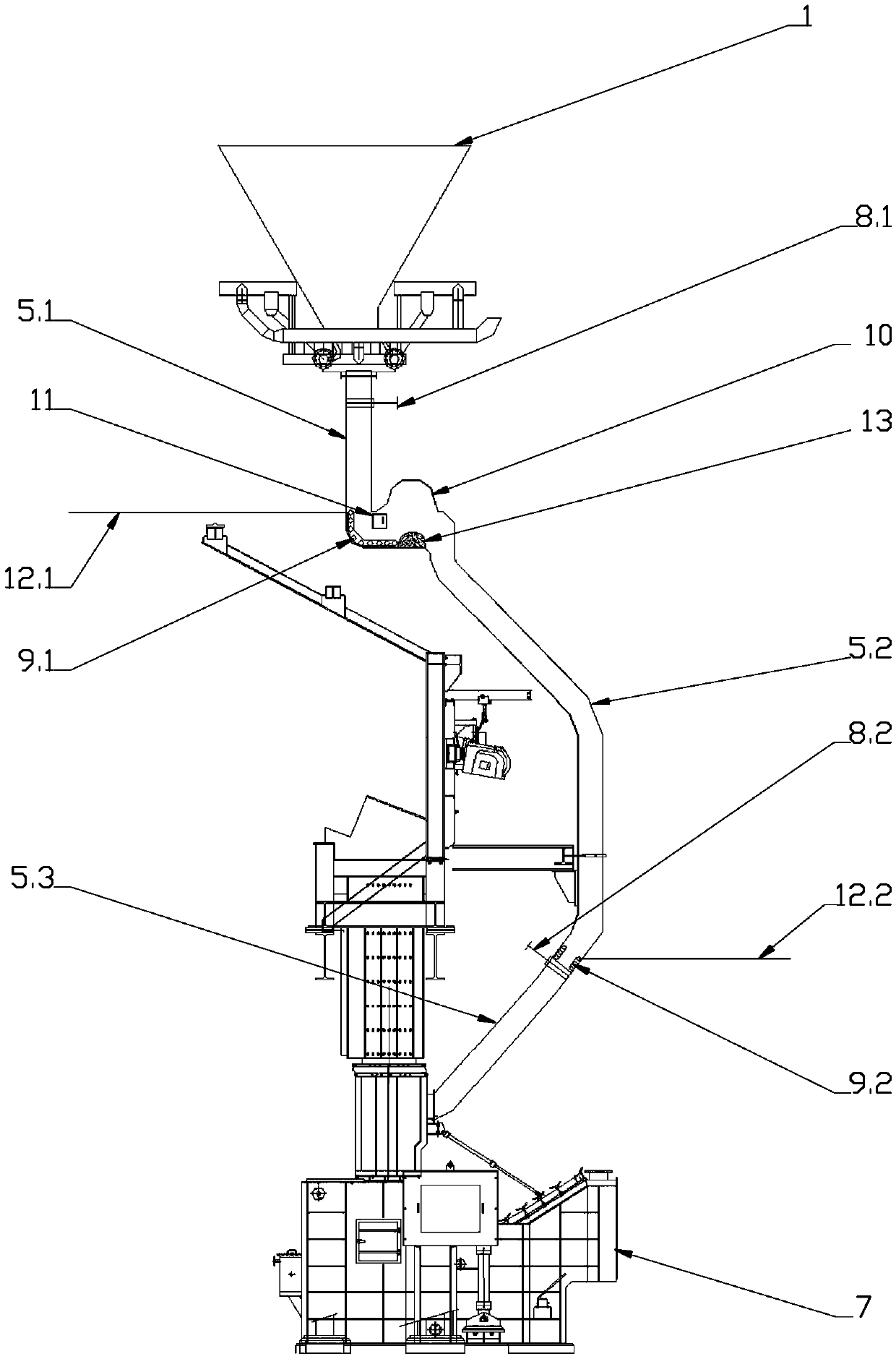

[0031] figure 1 It is a structural schematic diagram of an embodiment of the prior art. The figure shows that in the prior art, the waste incinerator fly ash conveying system mainly includes an ash collecting bucket 1, a water-cooled screw ash conveyor 2, a rotary ash unloading valve 3, a removal screw ash conveyor 4, an ash drop pipe 5, Advance the screw ash conveyor 6, the slag removal machine 7 and the slag removal pool; the fly ash falls into the ash collection hopper 1 through inertial capture, and then enters the rotary ash discharge valve 3 after passing through the water-cooled screw ash conveyor 2, and then enters the Remove the ash conveying screw 4, and finally enter the ash conveying screw 6 through the ash pipe 5. Because the components of the complex structure of the water-cooled ash conveyor 2 include heat exchange surfaces, the system rotation mechanism is large and complex, and the copper joints of the rotating water pipes of the water-cooled ash conveyor 2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com