Diamond wire breaking detection device and wire breaking prediction method thereof

A technology of disconnection detection and prediction method, applied in the direction of material capacitance, etc., can solve problems such as false alarm signals and delayed alarms, and achieve the effects of improving sensitivity, realizing disconnection monitoring, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0039] A diamond wire breakage detection device and a breakage prediction method thereof, wherein:

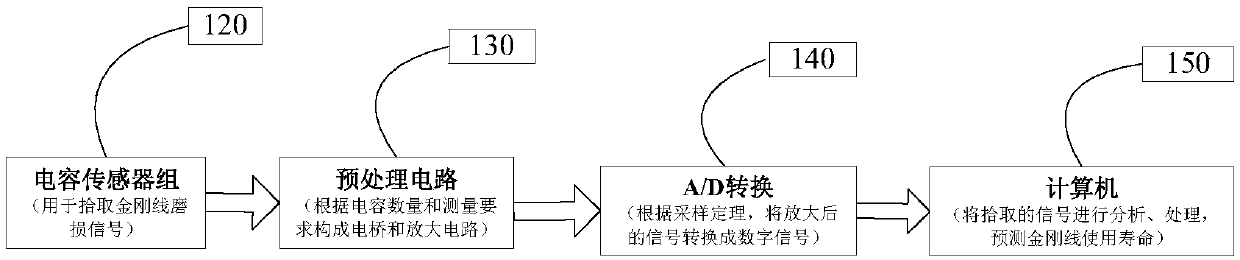

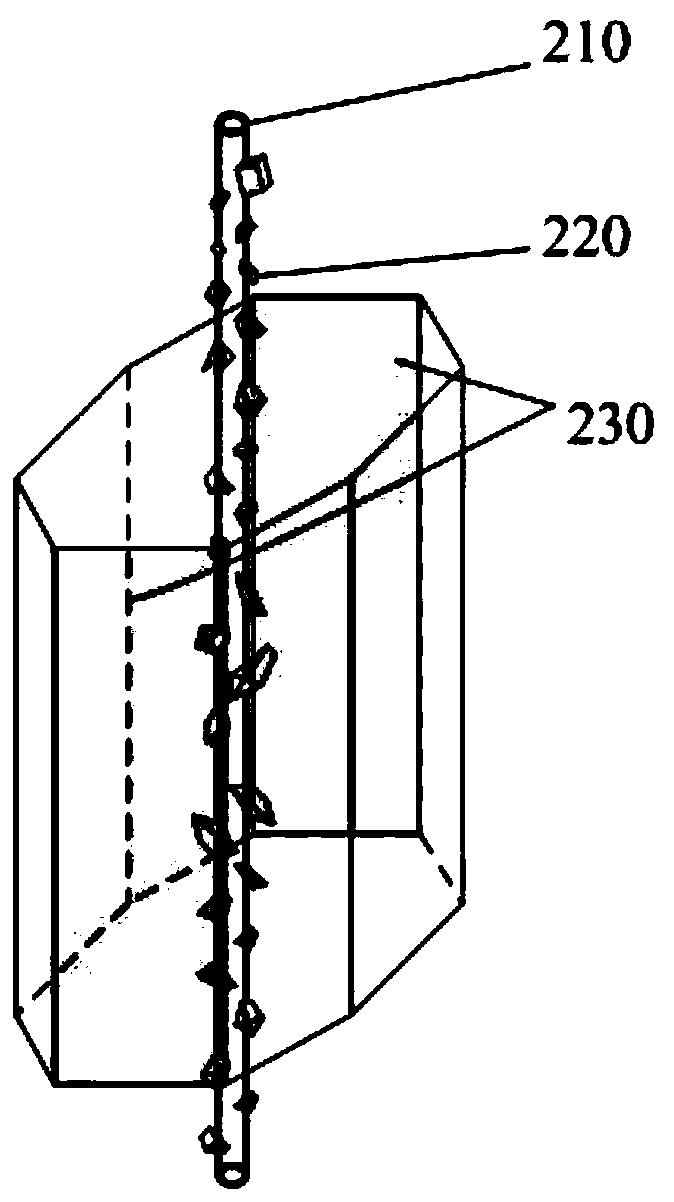

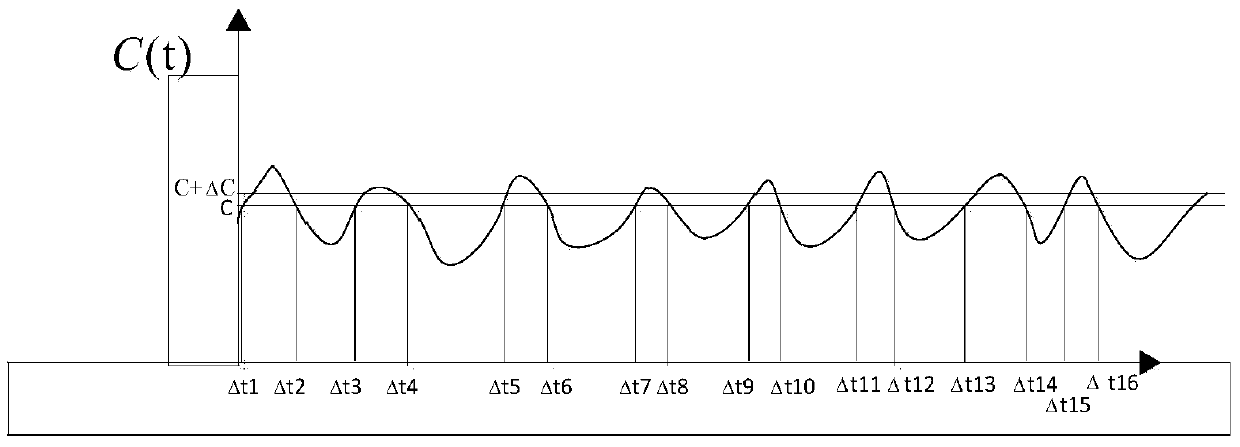

[0040] The diamond wire breakage detection device, such as figure 2 As shown, it includes a capacitive sensor group 120, a preprocessing circuit 130, an A / D converter 140 and a computer 150. The capacitive sensor group 120 monitors and detects the diamond wire in real time, and the diamond wires of different degrees of wear make the capacitive sensor group 120 Output corresponding capacitance value signals of different sizes, the capacitance value signals are filtered and amplified by the preprocessing circuit 130, so that the signal is fidelity and amplified to a recognizable strength, and the processed signal passes through the A / D converter 140 The data is transmitted to the computer 150, and the computer 150 performs statistical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com