Detection method for carbon content of globular graphite cast iron

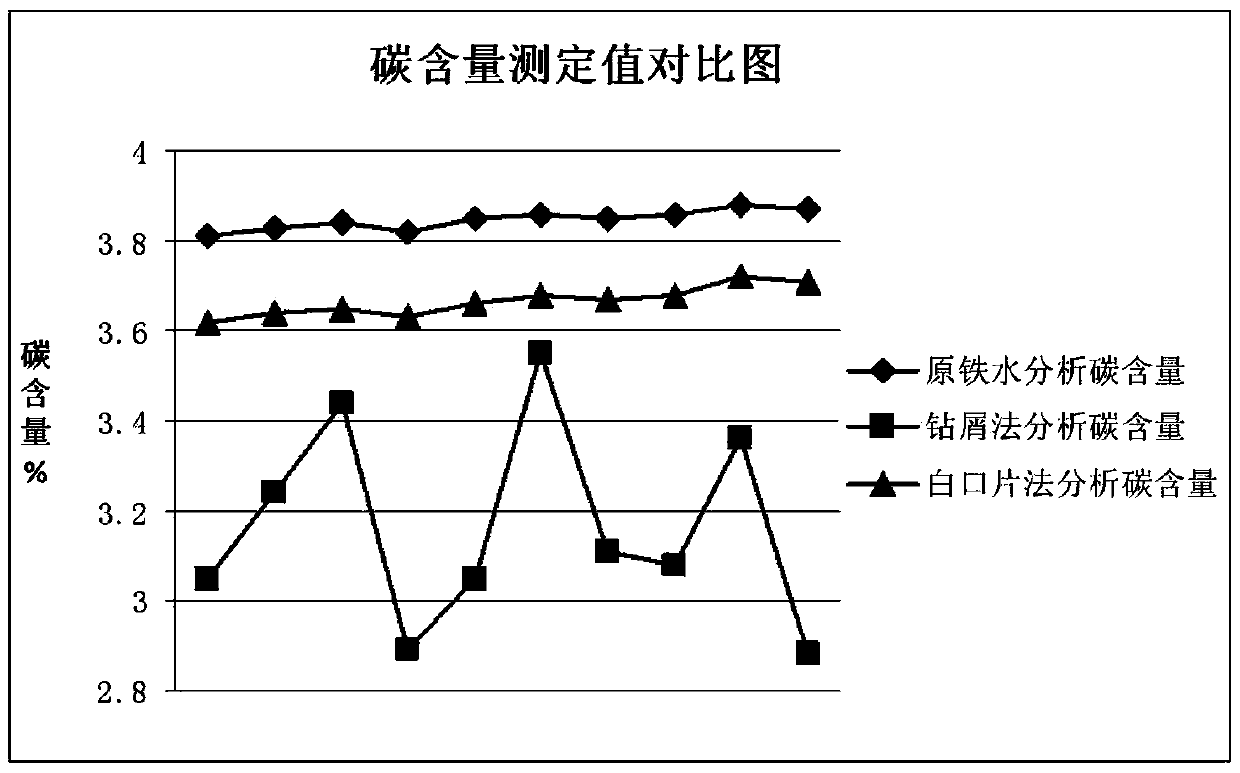

A technology of ductile iron and detection method, applied in the field of inspection and detection, can solve the problems of large fluctuation of carbon content detection data, loss of free graphite, low accuracy, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0015] A method for detecting the carbon content of ductile iron, comprising the steps of sampling, sample preparation, analysis, and measurement value reading, characterized in that: in the sampling step, a completely white sample of ductile iron is taken in a liquid state for analysis and reading of measured values.

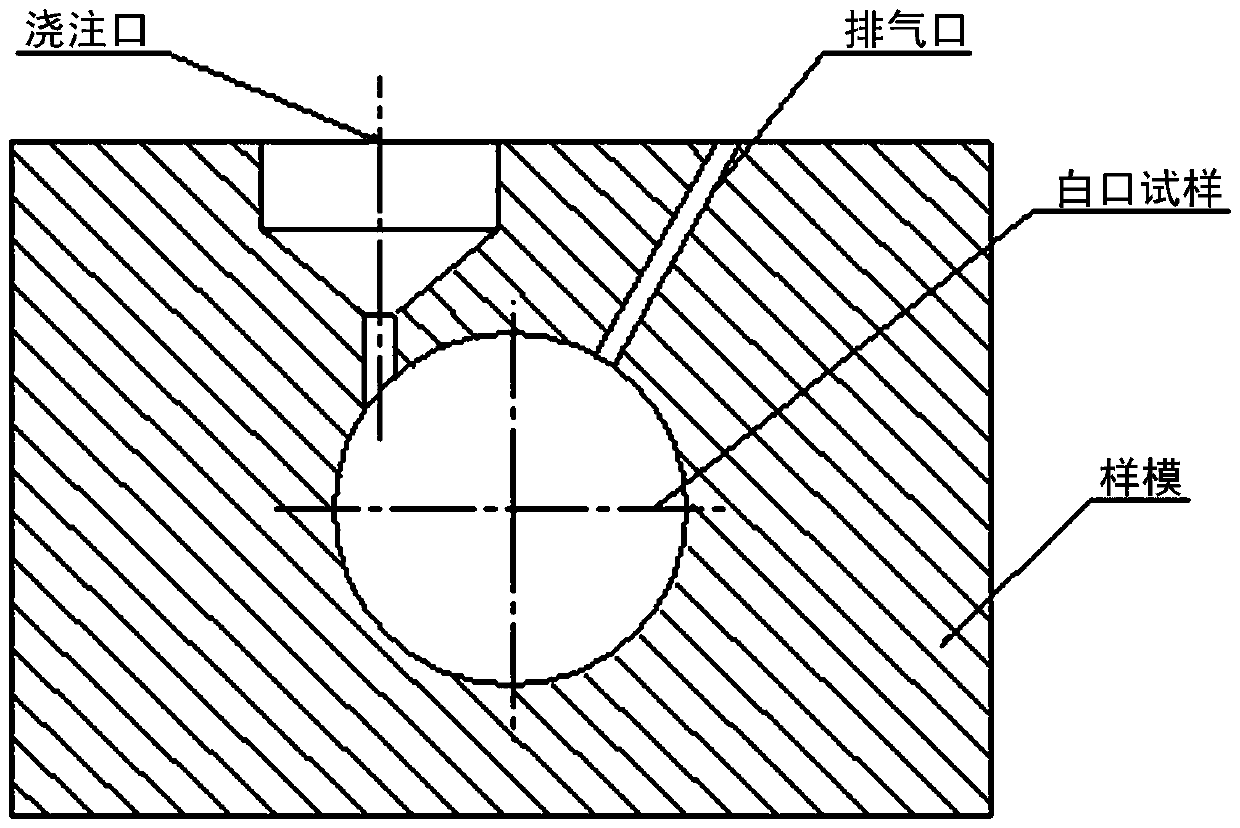

[0016] 1) Sampling: After the molten iron is spheroidized, take a white sample with a thickness of 1.5mm and a diameter of about 30mm in the liquid state. Such as figure 2 .

[0017] 2) Sample preparation: Grind the upper and lower surfaces of the white sample to remove surface oxides, leaving a thickness of about 0.5mm, and use a cleaning tool to smash the sample into pieces with a size of 2mm-4mm. Accurately weigh the flux and pure iron according to the operation requirements of the analytical instrument, and the carbon content of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com