Composite vibration energy collector

A vibration energy harvesting and composite technology, which is applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc., can solve the problems of single energy collection method and low energy collection efficiency , to achieve the effect of easy relative sliding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing.

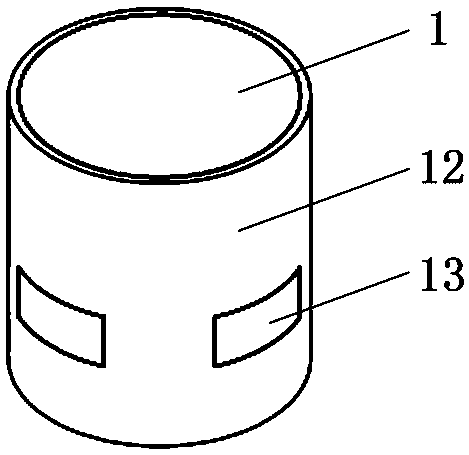

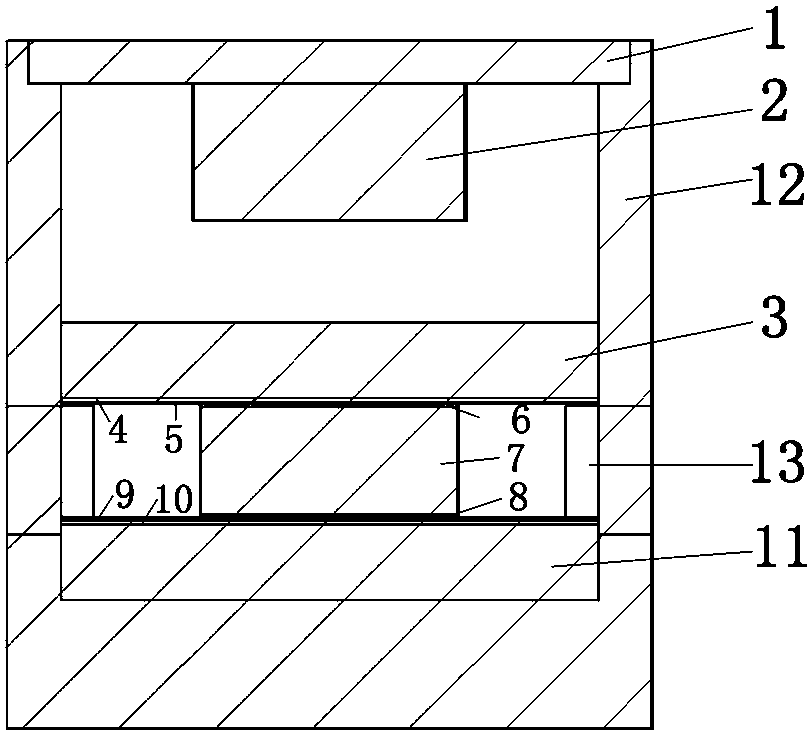

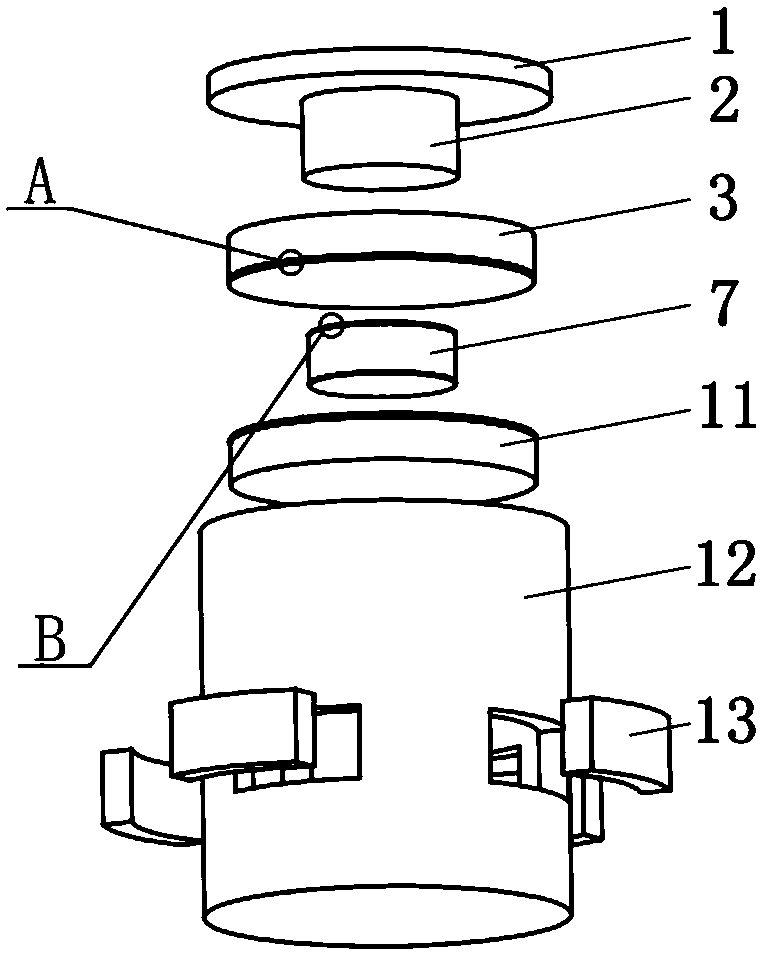

[0029] Such as Figure 1-Figure 9 As shown, a composite vibration energy harvester includes a housing 12 and a cover plate 1. The housing 12 is a hollow cylinder or a cuboid. The top of the housing 12 is provided with a port, and the cover plate 1 is fixed at the port. When the housing 12 When it is a hollow cylinder structure, the outer diameter of the shell can be designed as 30mm, the height of the shell is 32mm, the shell thickness of the shell is 2.5mm, and the cover plate is set as a cylinder with a diameter of 28mm and a height of 2mm, which is convenient to carry , In order to prevent the magnet from the force of the shell and the cover, the shell and the cover are made of non-magnetic materials. The casing 12 is provided with a first permanent magnet 2, an upper pyrolytic graphite plate 3, a first induction coil 4, a first friction layer 5, a second friction layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com