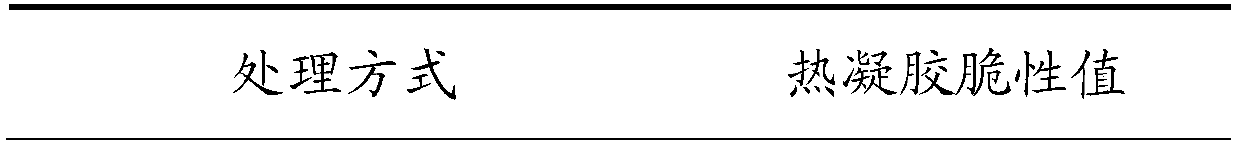

Processing method for improving thermal gel brittleness of myofibrillar protein

A technology of myofibrillar protein and a processing method is applied in the processing field of myofibrillar protein to improve thermal gel brittleness, and achieves the effects of easy preparation method, increased surface area and good thermal gel brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A processing method for improving the brittleness of myofibrillar protein thermal gel, comprising the following steps:

[0025] S1. Take 100g of fresh chicken breast and remove tendon, tendon, and fat, then mince it, add 4 times the volume of separation buffer (containing 100mmol / L KCl, 2mmol / L MgCl 2 , 1mmol / L EDTA, 10mmol / L K 2 HPO 4 , pH7.0), under the condition of 10000r / min, use a digital display high-speed dispersing homogenizer (FJ200-SH, Shanghai Specimen Model Manufacturing Factory) to disperse 3 times, each dispersing for 10s, and the interval between each dispersing is 10s;

[0026] S2. Centrifuge at 2500×g for 15 minutes, discard the supernatant, and take the precipitate; repeat the operation 3 times;

[0027] S3. Add 4 times the volume of NaCl solution (100mmol / L NaCl, pH6.0), disperse at 10000r / min for 10s, centrifuge at 2500×g for 15min after dispersion, discard the supernatant, and take the precipitate; repeat the operation 3 times to obtain Purified ...

Embodiment 2

[0036] S1. Take 100g of fresh chicken breast and remove tendon, tendon, and fat, then mince it, add 4 times the volume of separation buffer (containing 100mmol / L KCl, 2mmol / L MgCl 2 , 1mmol / L EDTA, 10mmol / L K 2 HPO 4 , pH7.0), under the condition of 10000r / min, use a digital display high-speed dispersing homogenizer (FJ200-SH, Shanghai Specimen Model Manufacturing Factory) to disperse 3 times, each dispersing for 10s, and the interval between each dispersing is 10s;

[0037] S2. Centrifuge at 2500 × g for 15 minutes, discard the supernatant, and take the precipitate; repeat this 3 times;

[0038] S3. Add 4 times the volume of NaCl solution (100mmol / L NaCl, pH6.0), disperse at 10000r / min for 10s, centrifuge at 2500×g for 15min after dispersion, discard the supernatant, and take the precipitate; after repeating this for 3 times, you get Purified myofibrillar protein precipitate;

[0039] S4. Put the purified myofibrillar protein precipitate into a bagged semi-permeable membra...

Embodiment 3

[0046] S1. Take 100g of fresh chicken breast and remove tendon, tendon, and fat, then mince it, add 4 times the volume of separation buffer (containing 100mmol / L KCl, 2mmol / L MgCl 2 , 1mmol / L EDTA, 10mmol / L K 2 HPO 4 , pH7.0), under the condition of 10000r / min, use a digital display high-speed dispersing homogenizer (FJ200-SH, Shanghai Specimen Model Manufacturing Factory) to disperse 3 times, each dispersing for 10s, and the interval between each dispersing is 10s;

[0047] S2. Centrifuge at 2500×g for 15 minutes, discard the supernatant, and take the precipitate; repeat the operation 3 times;

[0048] S3. Add 4 times the volume of NaCl solution (100mmol / L NaCl, pH6.0), disperse at 10000r / min for 10s, centrifuge at 2500×g for 15min after dispersion, discard the supernatant, and take the precipitate; repeat the operation 3 times to obtain Purified myofibrillar protein precipitate;

[0049] S4. Put the purified myofibrillar protein precipitate into a bagged semi-permeable me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com