Centrifugal machine table board fixing for acceleration test

A technology for fixing devices and centrifuges, applied in the field of centrifuges, can solve the problems of device damage, time-consuming and laborious installation of test pieces, and ignorance of the work surface, etc., so as to facilitate insertion, prevent damage to equipment and personnel, and ensure normal operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to enable those skilled in the art to better understand the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

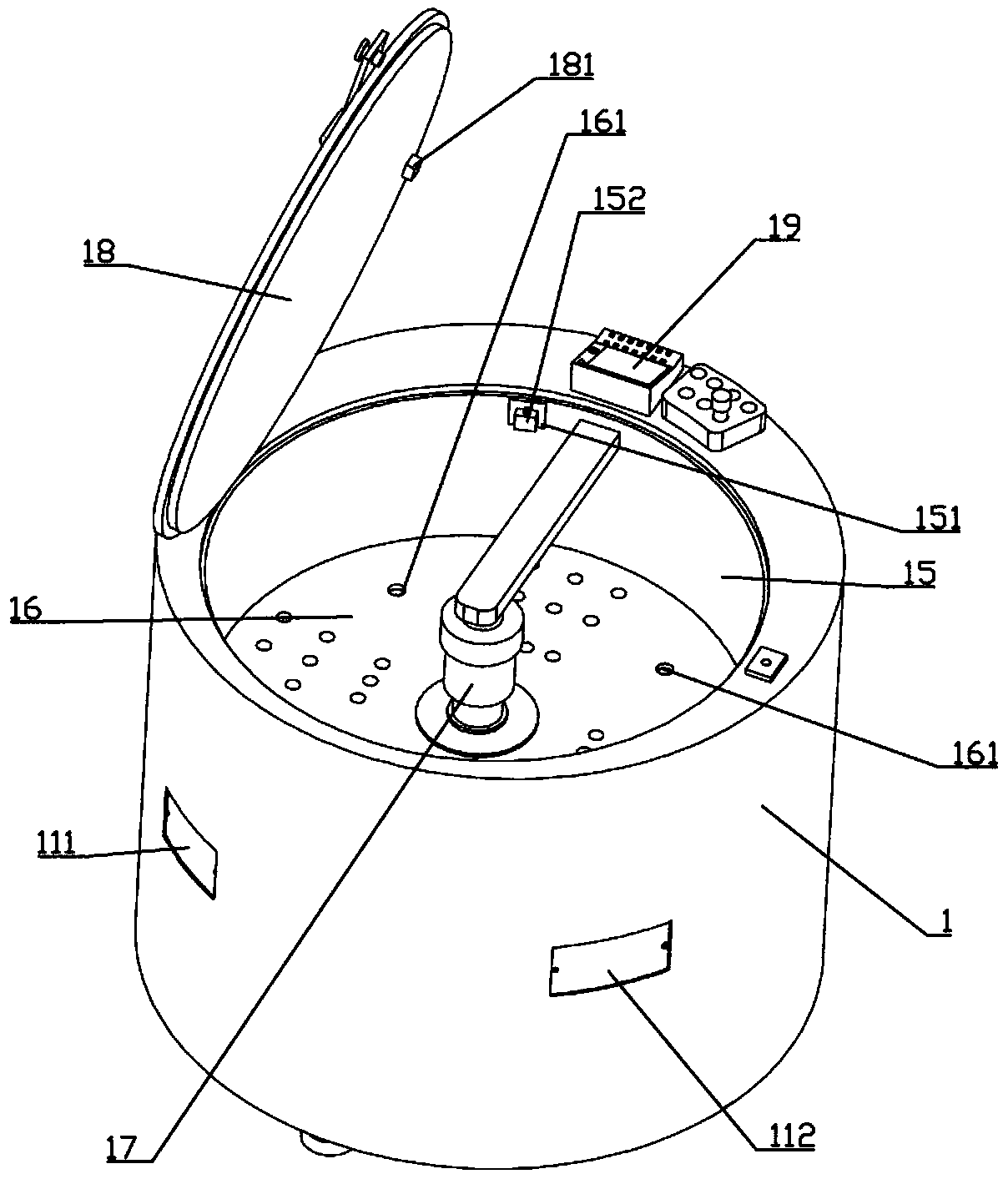

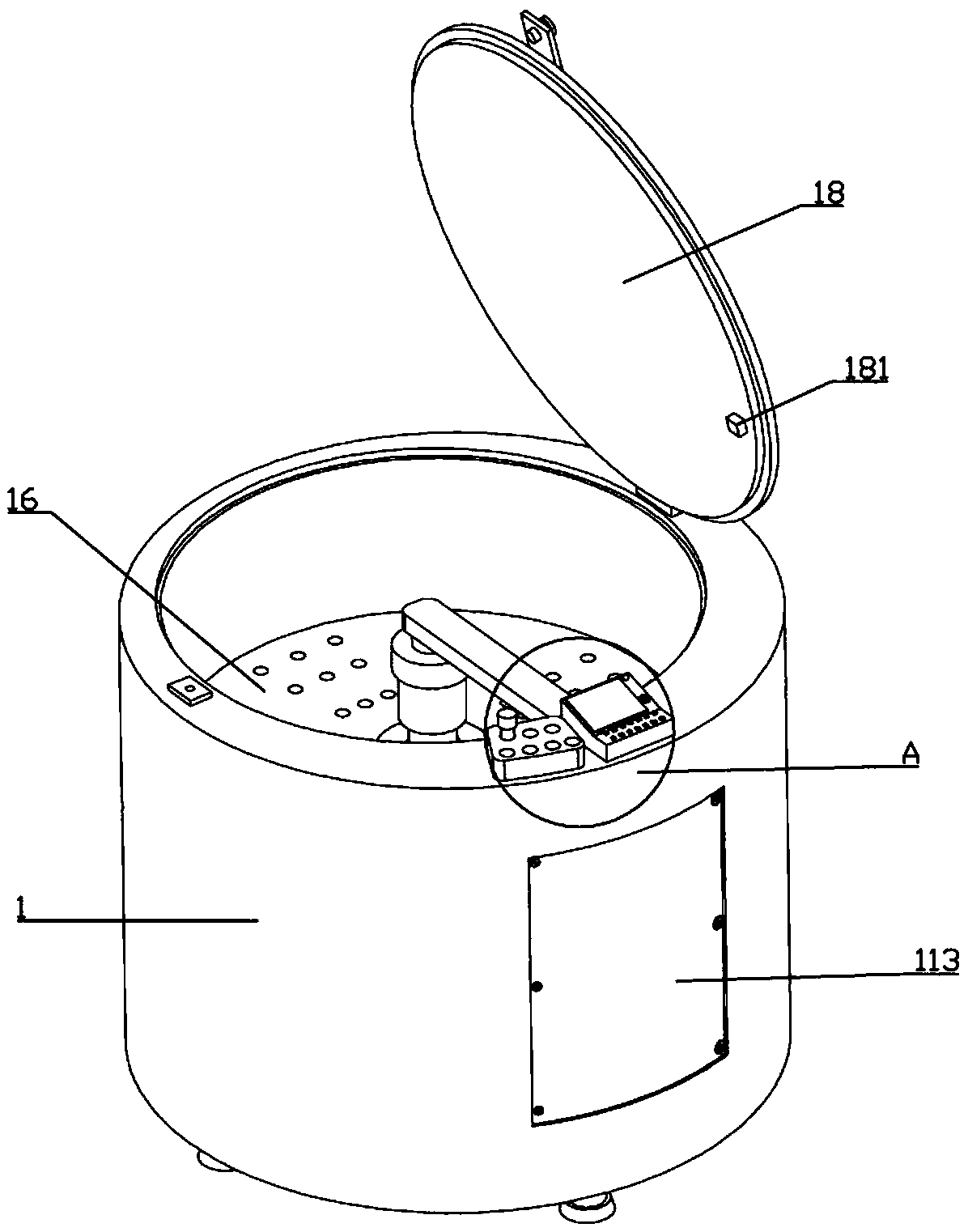

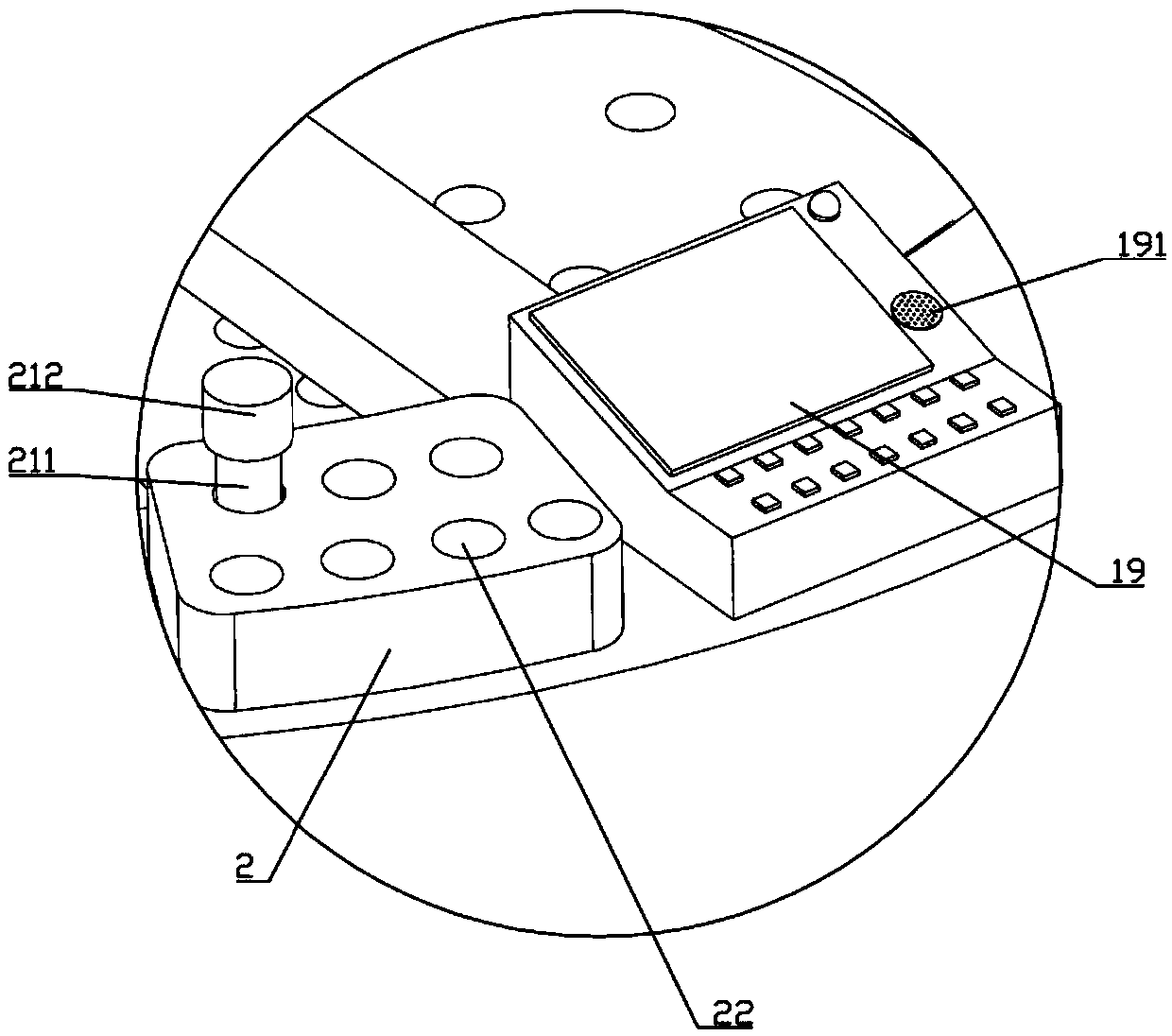

[0035] Such as Figure 1-6 As shown, a centrifuge table fixing device for an acceleration test of the present invention includes a frame guard plate 1, a bottom plate 11, a servo motor 12, a photoelectric encoder 121, a centrifuge support 13, a motor mounting seat 14, and a working chamber guard. Plate 15, working turntable 16, collector ring 17, cover plate 18 and processor 19, centrifuge support 13 includes support platform 131, frame guard plate 1 is hinged with cover plate 18, processor 19 is provided with processing chip and buzzer device 191, processor 19 side is provided with storage box 2, and storage box 2 is equipped with positioning pin 21, and positioning pin 21 comprises round rod 211, and round rod 211 upper end is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com