A Wedge Control Method with Deviation Protection

A control method, wedge-shaped technology, applied in the direction of contour control, rolling force/roll gap control, manufacturing tools, etc., can solve the problems of scrap steel deviation, low accuracy, slow response, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

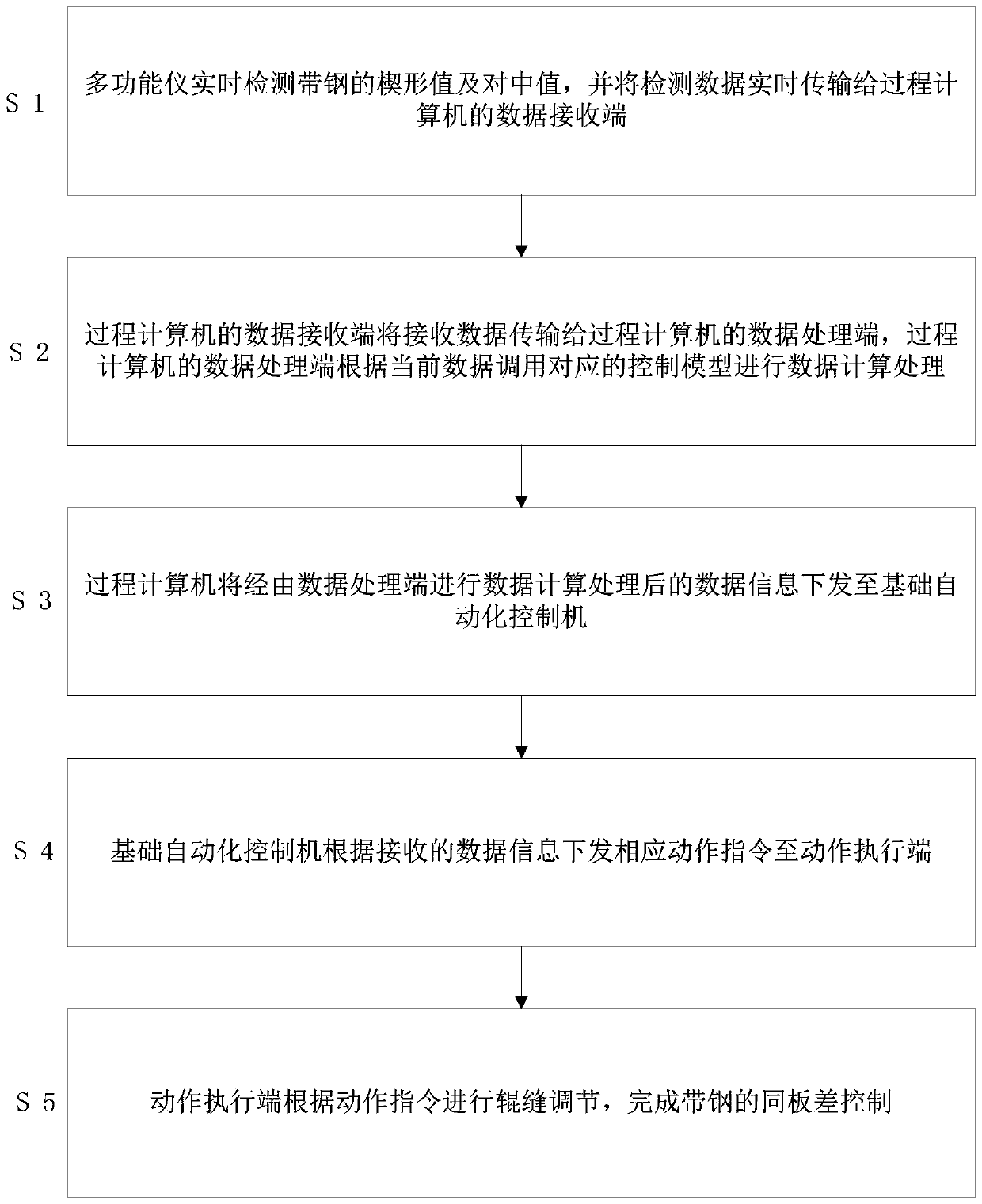

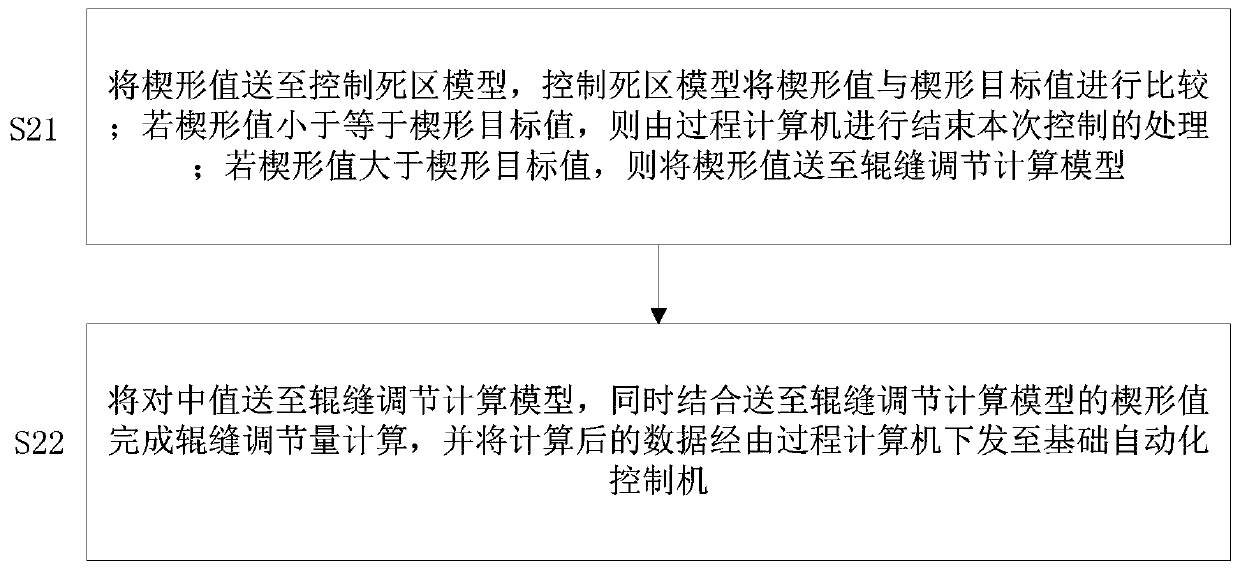

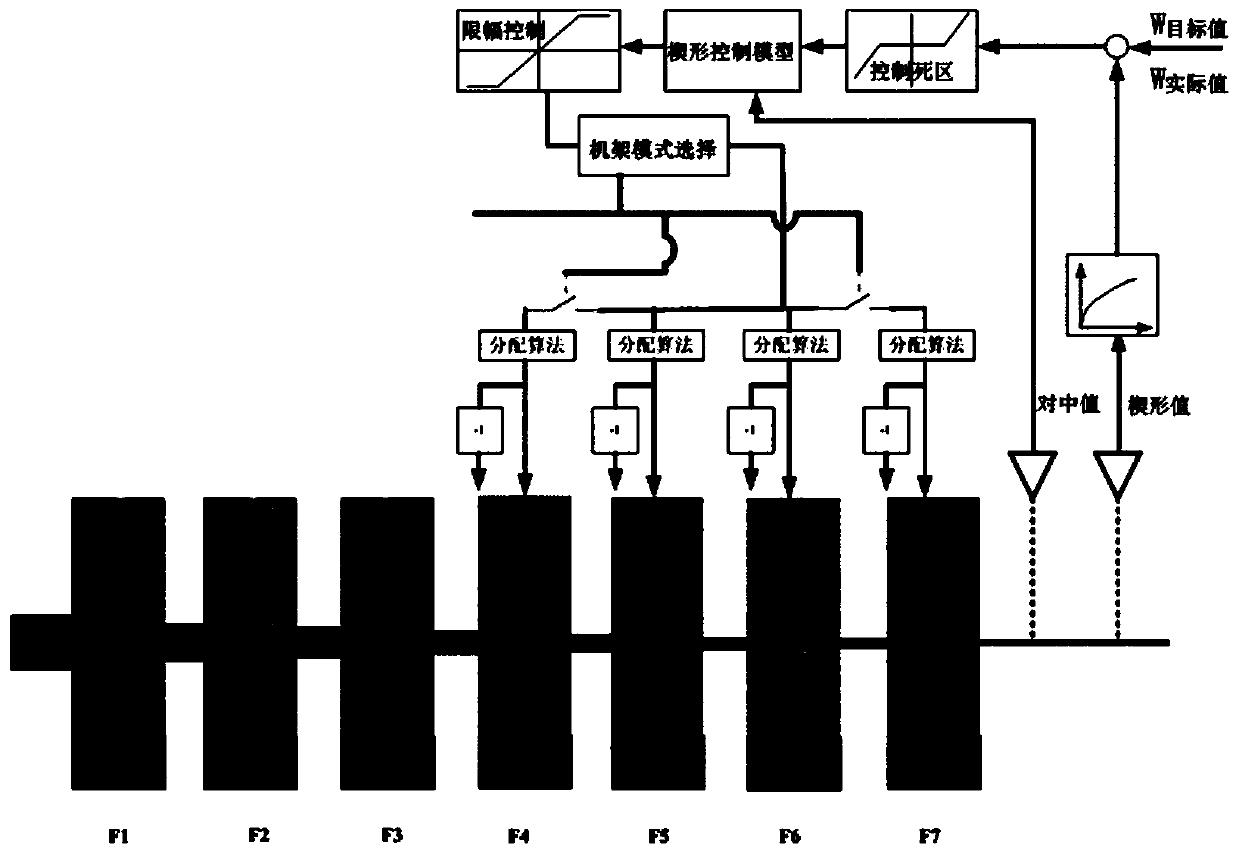

Method used

Image

Examples

Embodiment

[0086] For 1780 hot rolling production of a carbon steel strip product of a certain specification, the specification is 3.2×1450mm, and the target wedge shape is ≤20μm, the above method is used for control.

[0087] (1) Detection and dead zone processing of the exit wedge value of finishing rolling:

[0088] The wedge-shaped actual value We detected by the multi-function instrument for finishing rolling, if W e ≤δ (δ is the allowable value, take ±5um), no adjustment will be made.

[0089] (2) Determination of adjustment rack

[0090] The finishing rolling F4-F7 is selected as the adjustment stand, that is, under the condition that the wedge-shaped deviation detected at the finish-rolling exit exceeds the allowable range, the bending force of the F4-F7 stand is dynamically adjusted to make the strip wedge shape reach the target range.

[0091] (3) Determination of the adjustment amount of each rack

[0092] Calculate the unilateral roll gap adjustment amount of each frame ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com