Stir friction weld joint quality dynamic detection method based on torque

A friction stir welding and friction stir technology, which is applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of expensive equipment, real-time monitoring of the welding process, and inability to detect loose, incomplete penetration and close-fitting defects, etc. problem, to achieve the effect of simple and accurate method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below knot and accompanying drawing and example further illustrate the present invention.

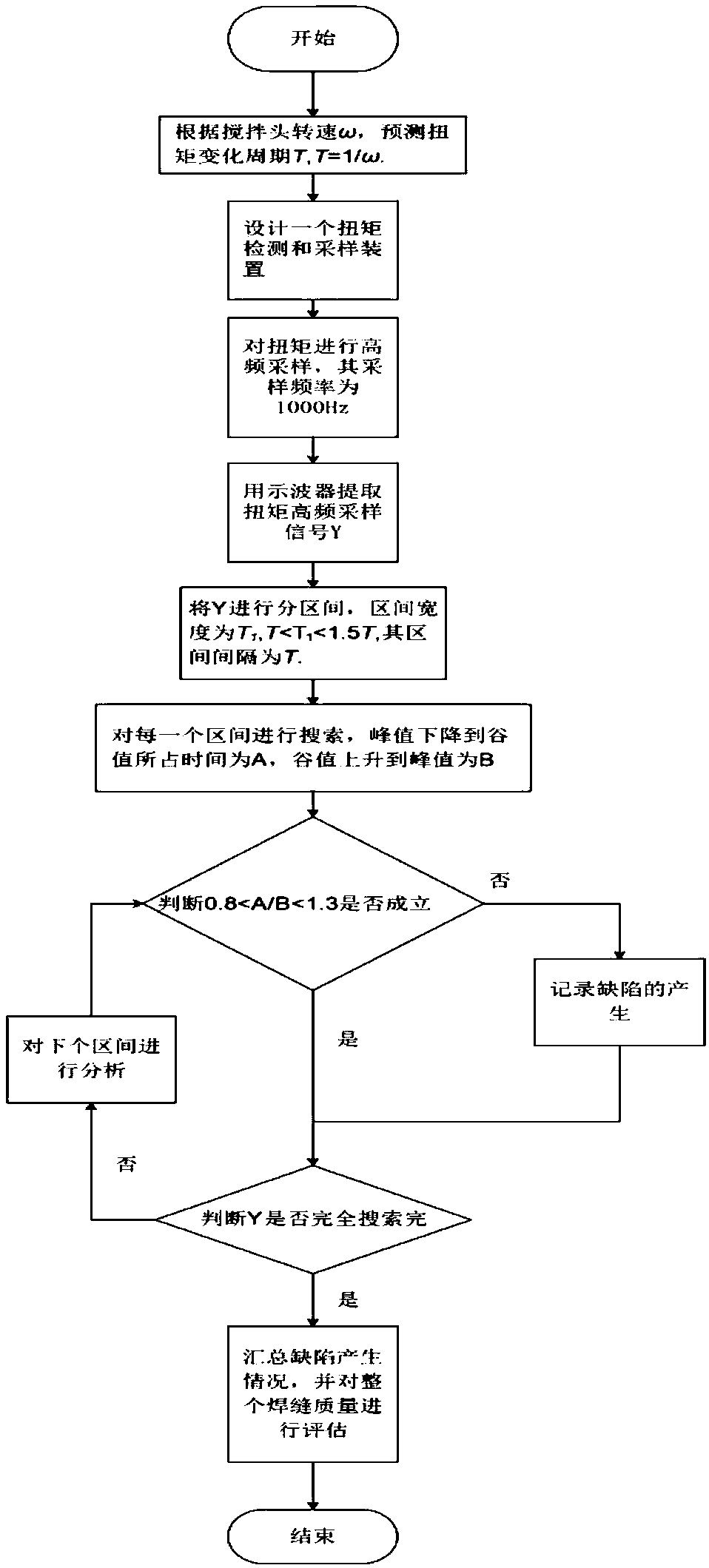

[0031] Take the rotation speed of the stirring head ω=600rpm, the forward speed of v=300mm / min, and the welding material is AA1104 aluminum alloy as an example. For the inspection process, see figure 1 .

[0032] Strp1: Place the friction stir welding workbench on the mechanical testing device.

[0033] Strp2: According to the preset stirring head speed to cycle T=1 / ω=1 / (600 / 60)×0.001=100ms

[0034] Strp3: Use torque high-frequency sampling equipment to perform high-frequency sampling of torque, and its frequency is 1000Hz

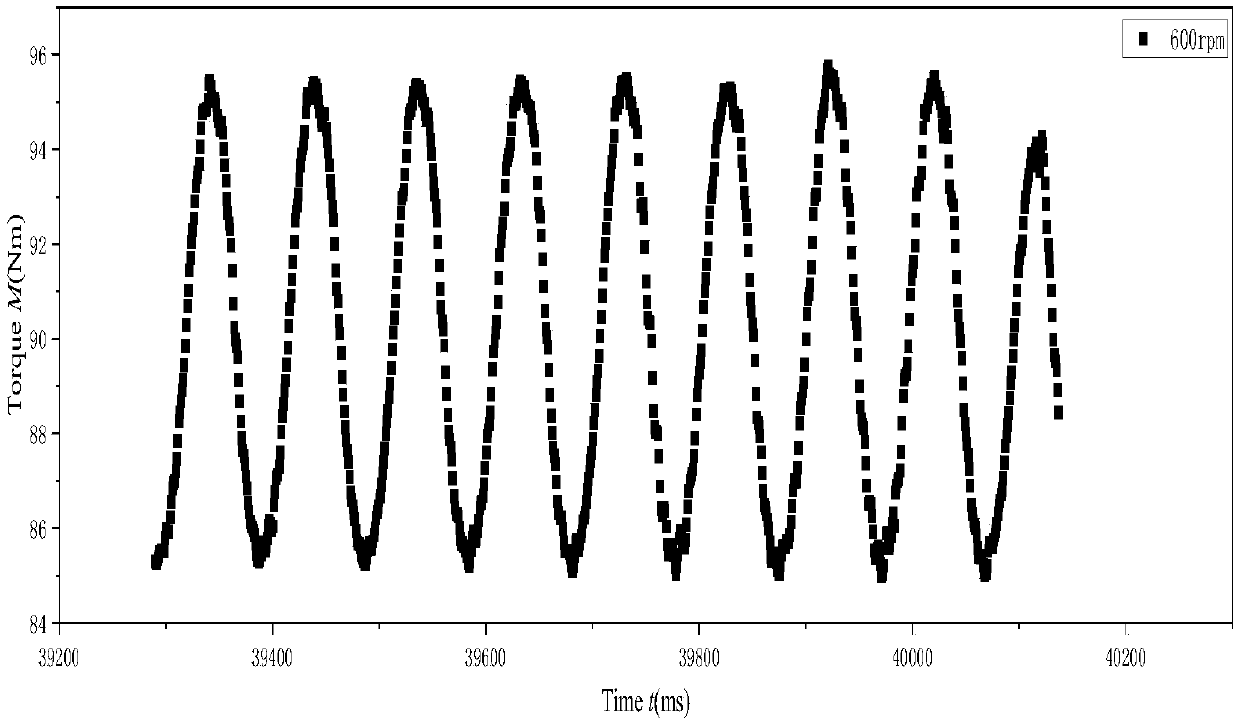

[0035] Strp4: Extract the torque high-frequency sampling signal Y through the oscilloscope, such as figure 2

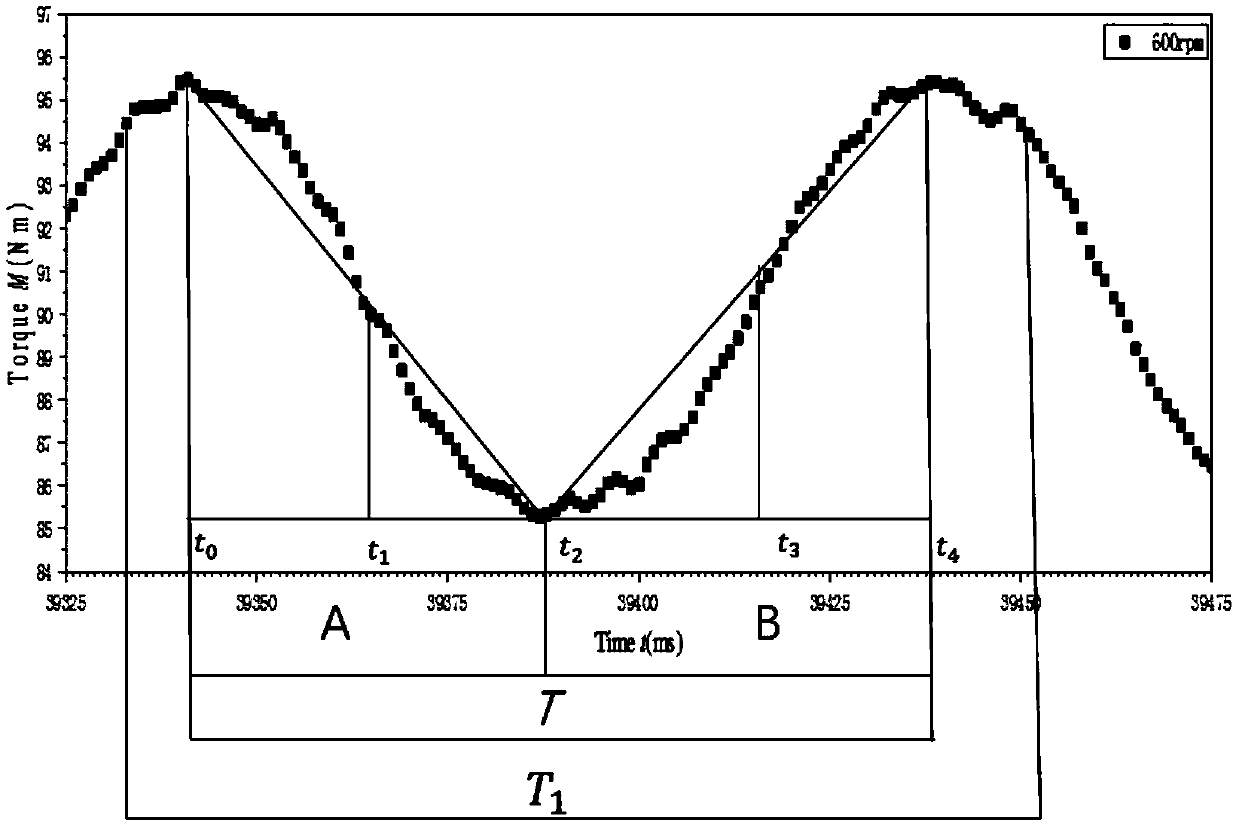

[0036] Strp5: Process the signal Y in partitions, the interval width is T 1 , the interval interval is T

[0037] Strp6: Search for the peak value and valley value of each interval, the time taken for the peak value to fall to the valley valu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com