Green brick code cutting process

A technology of adobe and technology, which is applied in the field of adobe cutting and coding technology, which can solve the problems of adobe falling, adding adobe, and excessively long conveying lines, and achieve the effects of reducing the probability of crushing, improving production efficiency, and shortening the conveying route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

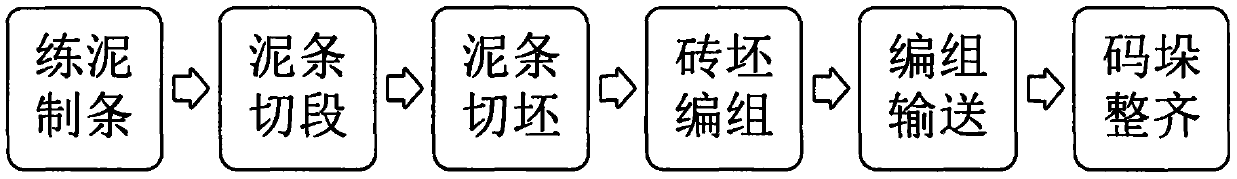

[0013] The adobe cutting and coding process of the present invention mainly relates to the adobe forming and stacking process in the production process of sintered bricks, and the production equipment involved mainly includes mud refining equipment, strip cutting machine, billet cutting machine, marshalling conveyor and stacking Machine, the concrete flow process of brick adobe cutting code process of the present invention is as figure 1 As shown, it mainly follows the following steps:

[0014] ①. First, mix and stir the mud evenly, and then extrude the mud strips through the mud refining equipment;

[0015] ②. Send the prepared mud strips into the strip cutter and cut them into mud strips according to the set size;

[0016] ③. Send the cut mud strips into the blank cutting machine and cut them into bricks;

[0017] ④. Each adobe is compiled into adobe group through the grouping conveyor in turn;

[0018] ⑤. The marshalling conveyor sends the compiled bricks to the stacking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com