Double-density molding in-mold foaming vulcanization molding rubber health sole and production technology thereof

A technology of vulcanization molding and double density, which is applied to shoe soles, footwear, footwear, etc., can solve the problems of insufficient elasticity, high cost, and time-consuming, and achieve the effects of low energy consumption, high bonding strength, and good composite effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

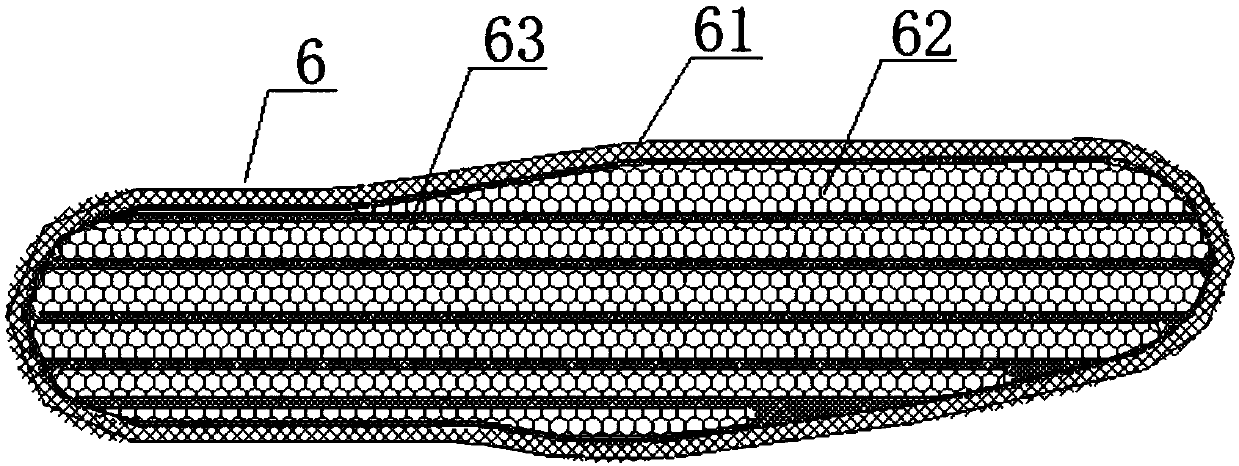

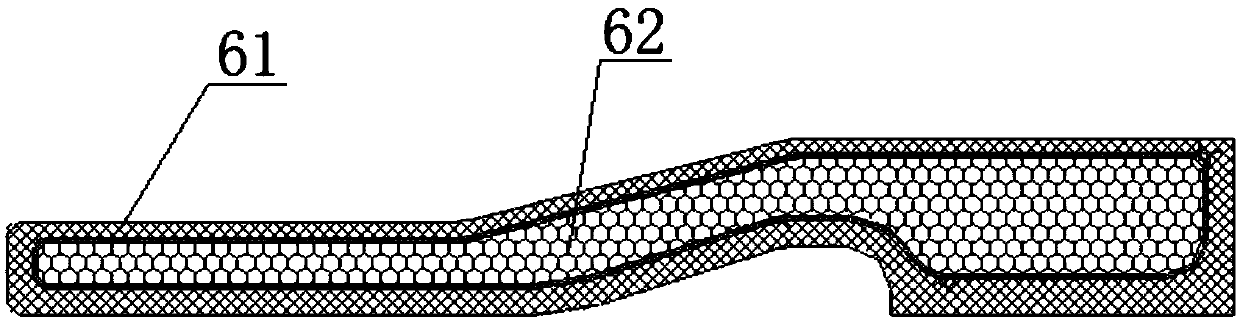

[0057] Foam vulcanization molding rubber health care shoe sole in the double density forming mold of the present embodiment, as figure 1 , 2 As shown, it includes a high-density outer layer 61 and a low-density inner layer 62, which is an integrated structure that is released from the same mold; the materials of the high-density outer layer 61 and the low-density inner layer 62 are high-density rubber and low-density rubber respectively. The low-density rubber is made by adding a foaming agent to the high-density rubber after foaming, and the dual-density injection in-mold foaming molding production system is used to complete the double-density rubber injection, foaming and vulcanization processes in one mold. Effectively avoid the circulation of products in each process, thereby reducing production costs. The density ratio of the high-density outer layer 61 and the low-density inner layer 62 can be 2:1, wherein the density of the high-density outer layer 61 is 1000kg / m 3 . ...

Embodiment 2

[0059] The foaming and vulcanization molding rubber health-care shoe sole in the double-density forming mold of the present embodiment has the same basic structure as that of Embodiment 1, and the improvements are as follows:figure 1 , 2 As shown, a spring support 63 is embedded in the low-density inner layer 62 to play the role of skeleton support. The spring elasticity can be selected to be consistent with the elasticity of the low-density rubber to strengthen the support strength of the low-density inner layer 62 and slow down the low-density inner layer. 62. Elastic attenuation caused by frequent deformation. In the vertical distribution, 5 springs can be distributed. Cooperating with the direction of each toe, it can coordinate the rich vertical veins of the feet and play an effective role in massage and health care. The spring supports 63 diameters Slightly smaller than the thickness of the low-density inner layer 62 to avoid the hard contact between the sole of the foot ...

Embodiment 3

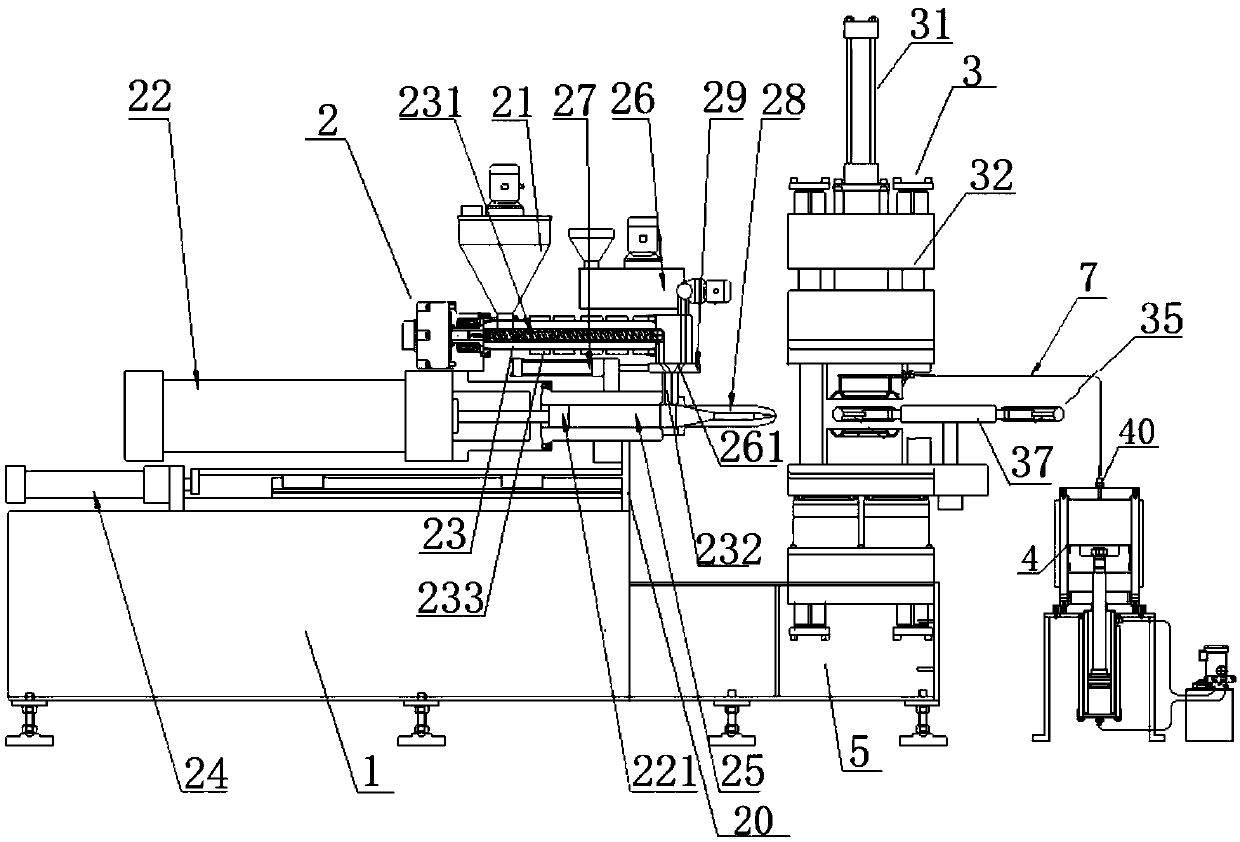

[0061] The foam vulcanization molding rubber health-care shoe sole in the double-density molding mold of the present embodiment is used to produce the basic structure of the double-density molding production system injected into the rubber shoe sole. The improvement is as follows: image 3 As shown, the injection device 2 in the double-density injection in-mold foam molding production system includes a hopper 21, an injection cylinder 22, a plasticizing injection screw barrel 23, an injection seat moving cylinder 24, a pre-injection chamber 25, a rubber plastic chemical machine 26, material switching oil cylinder 27, injection head 28 and material switching switching valve 29; the feeding hopper 21 communicates with the beginning of the plasticizing injection screw barrel 23, and the plasticizing injection screw barrel 23 is fixed on the end of the injection oil cylinder 22 side; the plasticizing injection screw barrel 23 and the discharge port of the rubber plasticizing machin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com