Double-peak nano-porous amorphous alloy and preparation method thereof

A technology of amorphous alloy and nanoporous, which is applied in the field of bimodal nanoporous amorphous alloy and its preparation, can solve the problems of complex equipment cost, single pore structure, complex technology, etc., and is conducive to large-scale industrial production and preparation The process is simple, and the effect of solving the technical complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

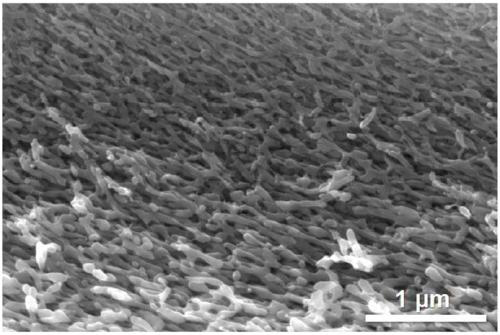

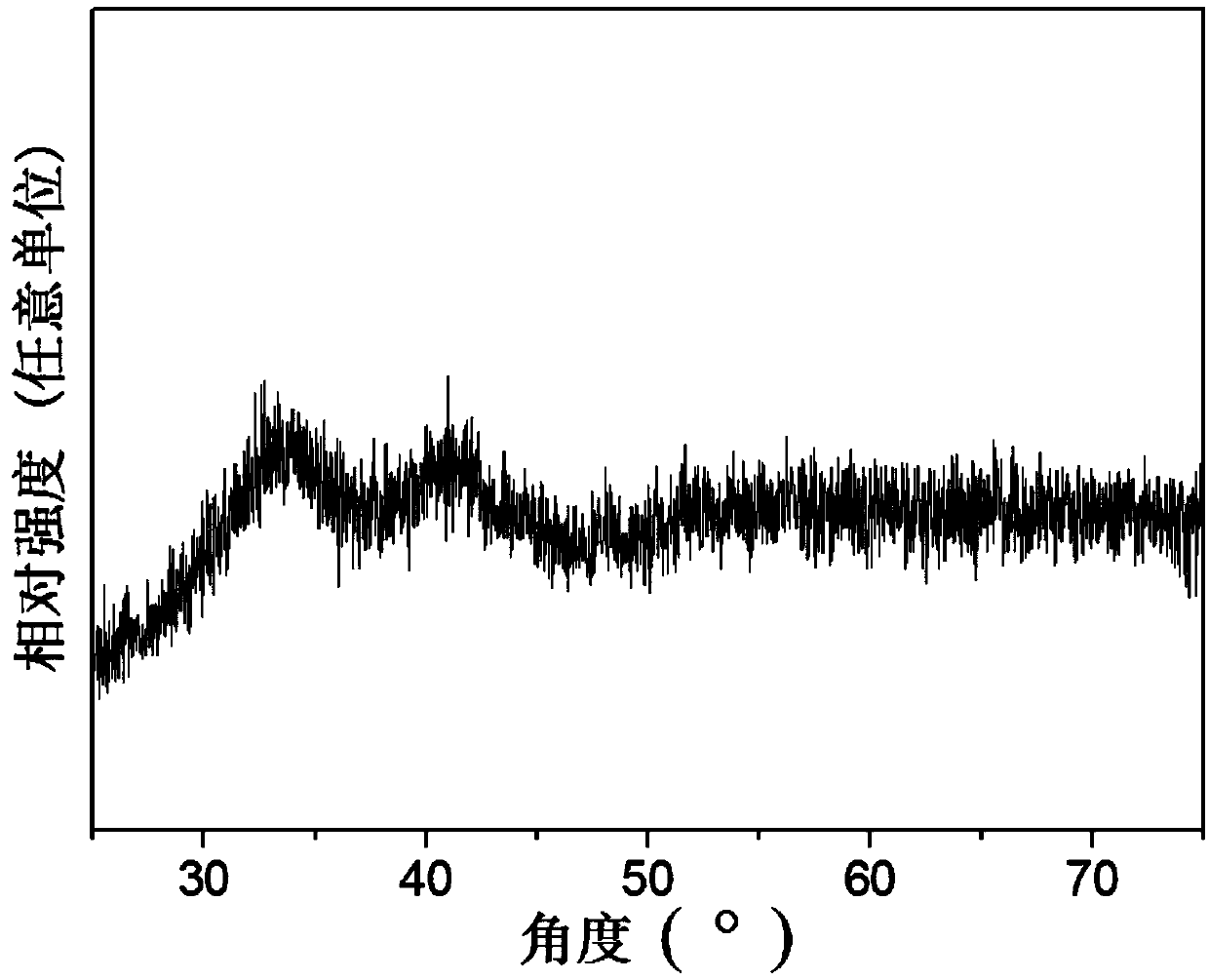

Embodiment 1

[0033] The first step is to prepare dual-phase amorphous alloy thin strips

[0034] Select high-purity Y, Ti, Co and Al metals as raw materials, the mass purity of the four elements is 99.99wt%, and then according to the target composition Y 28 Ti 28 co 20 Al 24 Weigh each component element, prepare a total of 6g of raw materials, and the marked components are atomic percentages; place the configured 6g of metal raw materials in a vacuum electric arc furnace, and evacuate until the air pressure is 3.0×10 -3 Pa, filled with argon (volume purity of 99.99%), the pressure of argon is 3 × 10 -2 Start arc melting under the condition of MPa, the melting current is 100A, repeat the melting 3 times, each time for 30s, to ensure the uniformity of the alloy structure, and obtain Y 28 Ti 28 co 20 Al 24 Master alloy ingot; take 3g of master alloy ingot and carry out induction melting under the protection of high-purity argon (volume purity 99.99%), and the vacuum degree in the furna...

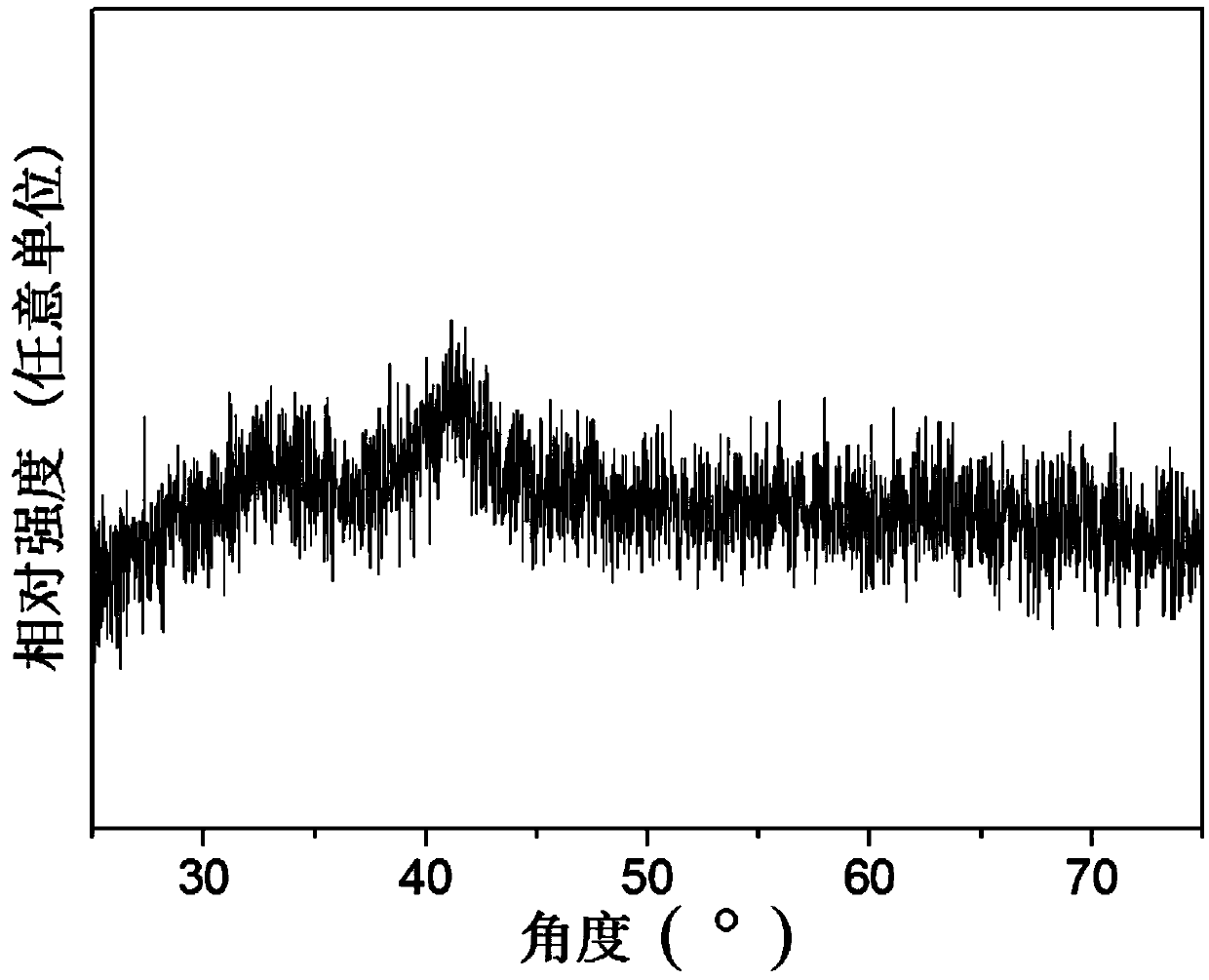

Embodiment 2

[0041] The first step is to prepare amorphous alloy thin strips

[0042] Select high-purity Y, Ti, Co and Al metals as raw materials, the mass purity of the four elements is 99.99wt%, and then according to the target composition Y 28 Ti 28 co 20 Al 24 Weigh each component element, prepare a total of 6g of raw materials, and the marked components are atomic percentages; place the configured 6g of metal raw materials in a vacuum electric arc furnace, and evacuate until the air pressure is 3.0×10 -3 Pa, filled with argon (volume purity of 99.99%), the pressure of argon is 3 × 10 -2 Under the condition of MPa, the arc melting was started, the melting current was 70A, and the melting was repeated 4 times, 20s each time, to ensure the uniformity of the alloy structure, and Y was obtained after cooling with the furnace. 28 Ti 28 co 20 Al 24 Master alloy ingot; take 3g of master alloy ingot and carry out induction melting under the protection of high-purity argon (volume purity...

Embodiment 3

[0049] The first step is to prepare amorphous alloy thin strips

[0050] Select high-purity Y, Ti, Co and Al metals as raw materials, the mass purity of the four elements is 99.99wt%, and then according to the target composition Y 28 Ti 28 co 20 Al 24 Weigh each component element, prepare a total of 6g of raw materials, and the marked components are atomic percentages; place the configured 6g of metal raw materials in a vacuum electric arc furnace, and evacuate until the air pressure is 3.0×10 -3 Pa, filled with argon (volume purity of 99.99%), the pressure of argon is 3 × 10 -2 Under the condition of MPa, the arc melting was started, the melting current was 90A, and the melting was repeated twice, each time for 25s, to ensure the uniformity of the alloy structure, and Y was obtained after cooling with the furnace. 28 Ti 28 co 20 Al 24 Master alloy ingot; take 3g of master alloy ingot and carry out induction melting under the protection of high-purity argon (volume puri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com