Concrete-filled steel tube pier

A steel tube concrete and concrete technology, applied in the direction of bridges, bridge parts, bridge materials, etc., can solve the problems of affecting disaster relief, long repair time, difficult repair, etc., and achieve the effect of alleviating urban traffic congestion, short construction period and fast construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

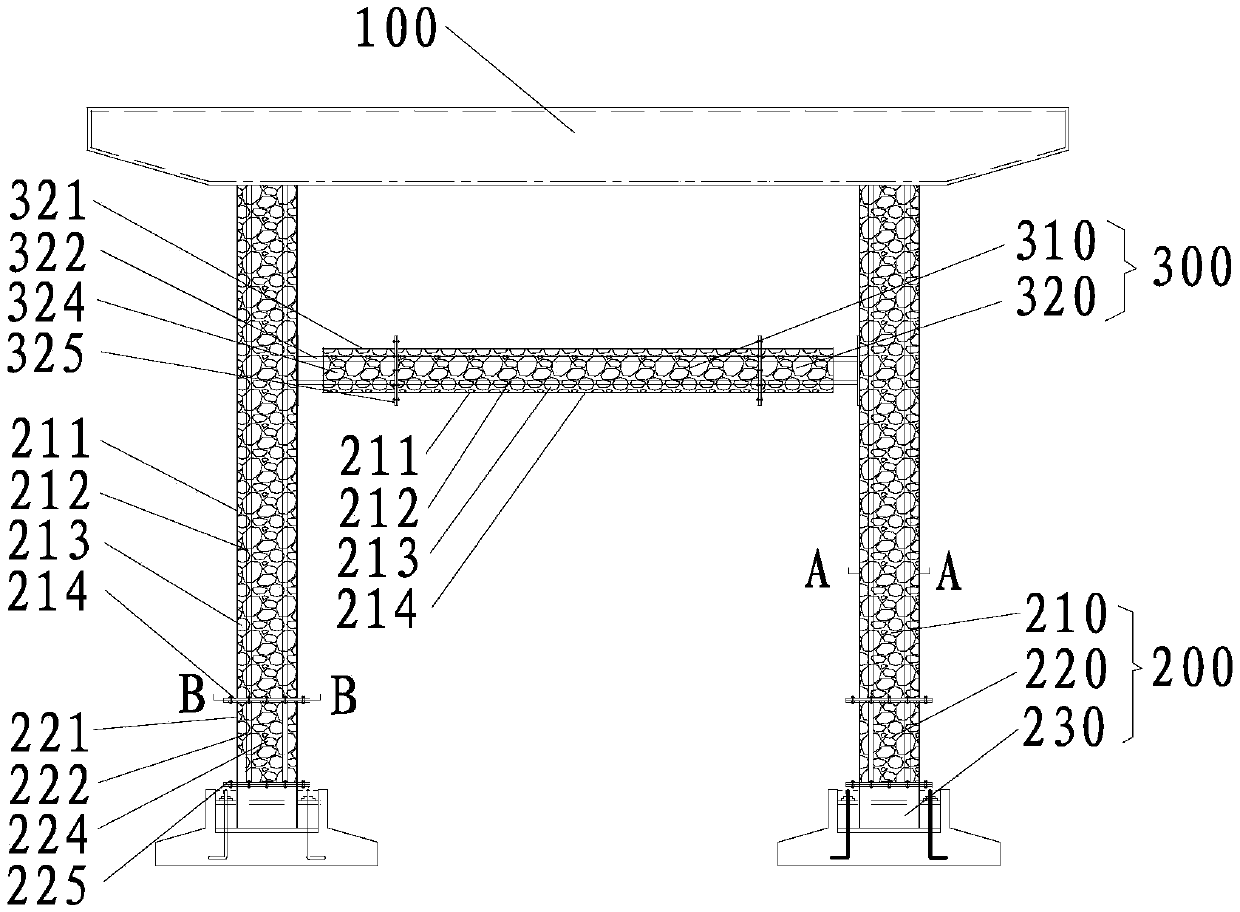

[0039] Such as Figure 1-Figure 5 As shown, the steel pipe concrete bridge pier provided in this embodiment includes a beam 100, two or more pier columns 200 located below the beam 100 for supporting the beam 100, and a tie beam 300 connected between two adjacent pier columns 200, wherein , the number of piers 200 can be set according to actual needs, and in this embodiment, two piers 200 are taken as an example for illustration.

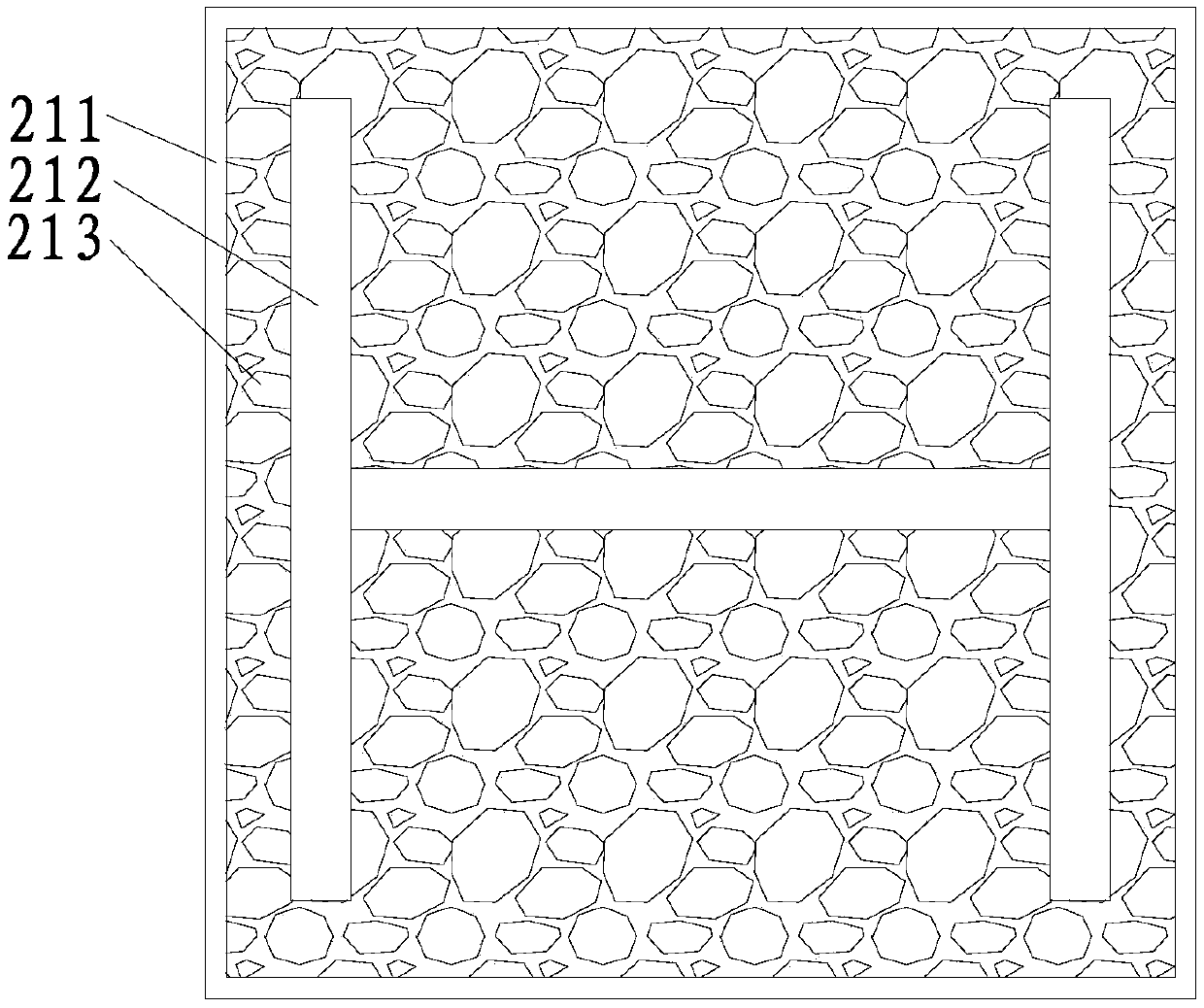

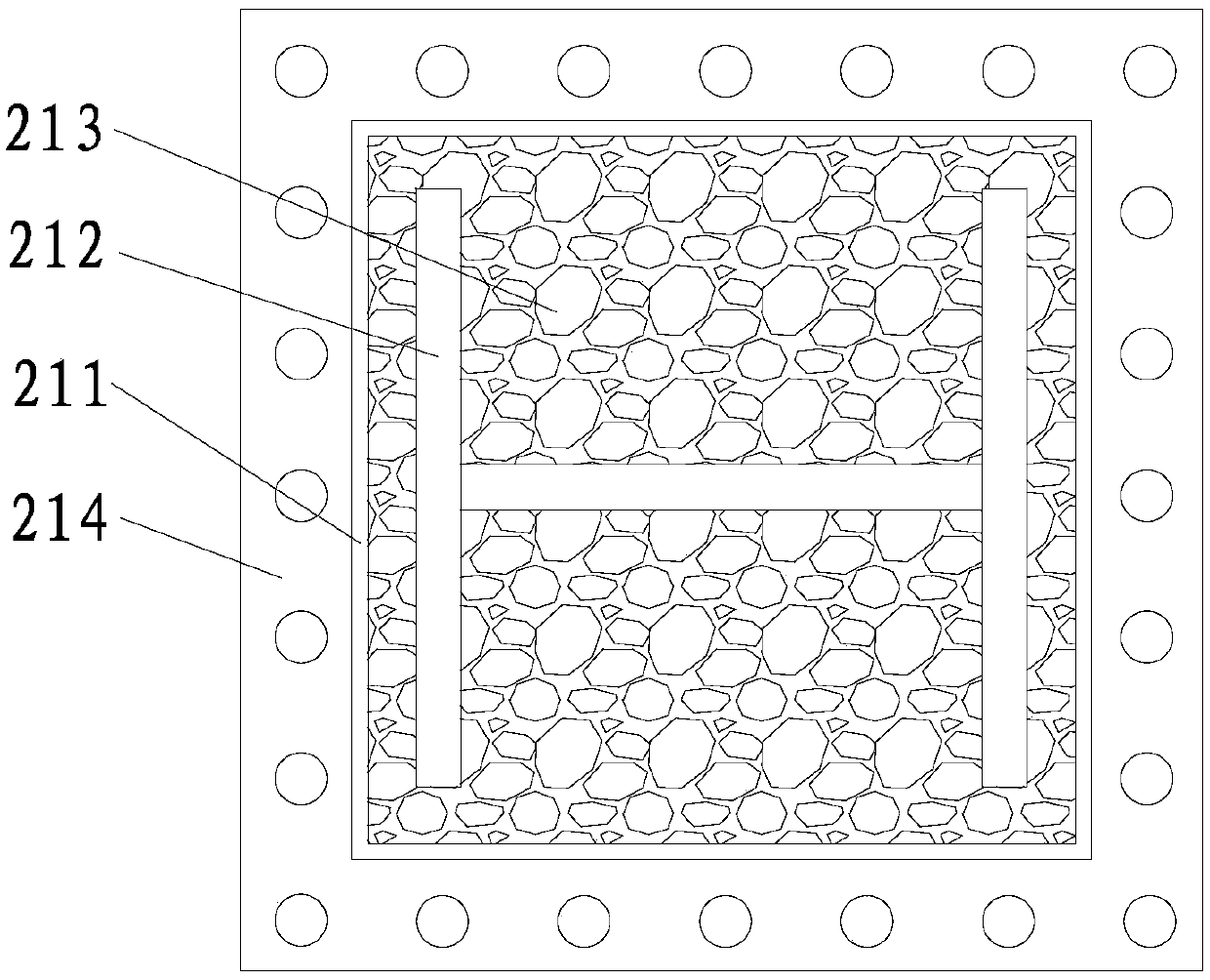

[0040] The tie beam 300 includes a tie beam main body 310 arranged horizontally and tie beam energy dissipating components 320 fixedly connected to both ends of the tie beam main body 310 , that is, there are two tie beam energy dissipating components 320 . The tie beam main body 310 includes a first steel pipe 311, a first hose inner core 312 inserted in the first steel pipe 311, a first concrete 313 filled between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com