Building slope roof fabricated construction process

A construction technology and prefabricated technology, applied in roofs, buildings, building components, etc., can solve the problems of high labor intensity, weak ability to resist natural disasters, labor-intensive labor intensity, etc., to save resources, save project costs, and reduce self-weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

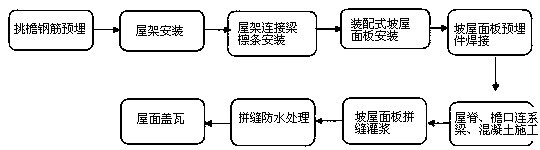

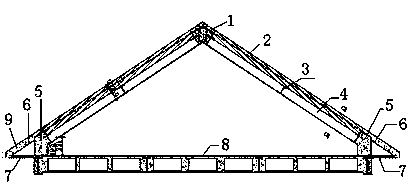

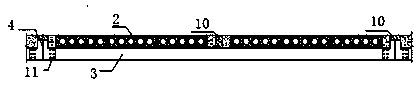

[0035] Such as figure 1 , figure 2 , image 3 As shown, the construction process of the present invention is: pre-embedded eaves reinforcement → roof truss installation → roof truss connecting beam purlin installation → prefabricated sloping roof panel installation → sloping roof panel embedded parts welding → roof ridge, cornice connection beam concrete pouring construction → Joint grouting of sloping roof panels → seam waterproofing treatment → roof tiling.

[0036] Overhanging eaves reinforcement 9 Pre-embedded: When the overhanging eaves reinforcement is pre-embedded and bound, the overhanging eaves reinforcement is directly tied with the top floor reinforcement at the same time, and the overhanging eaves bottom slab concrete and the top floor are cast together to form a whole. At the same time, protect the reserved steel bars on the top of the overhanging eaves so as to ensure the overall anchorage of the steel bars on the overhanging slope and the connecting beams o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com