Coal seam gas extraction method based on controllable impact wave technology

A technology of coal seam gas and shock wave, which is applied in the field of coal seam gas drainage based on controllable shock wave technology, can solve problems such as high cost, poor anti-reflection effect, and lack of safety control, and achieve time saving, good safety control, and increased good see-through effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with accompanying drawing.

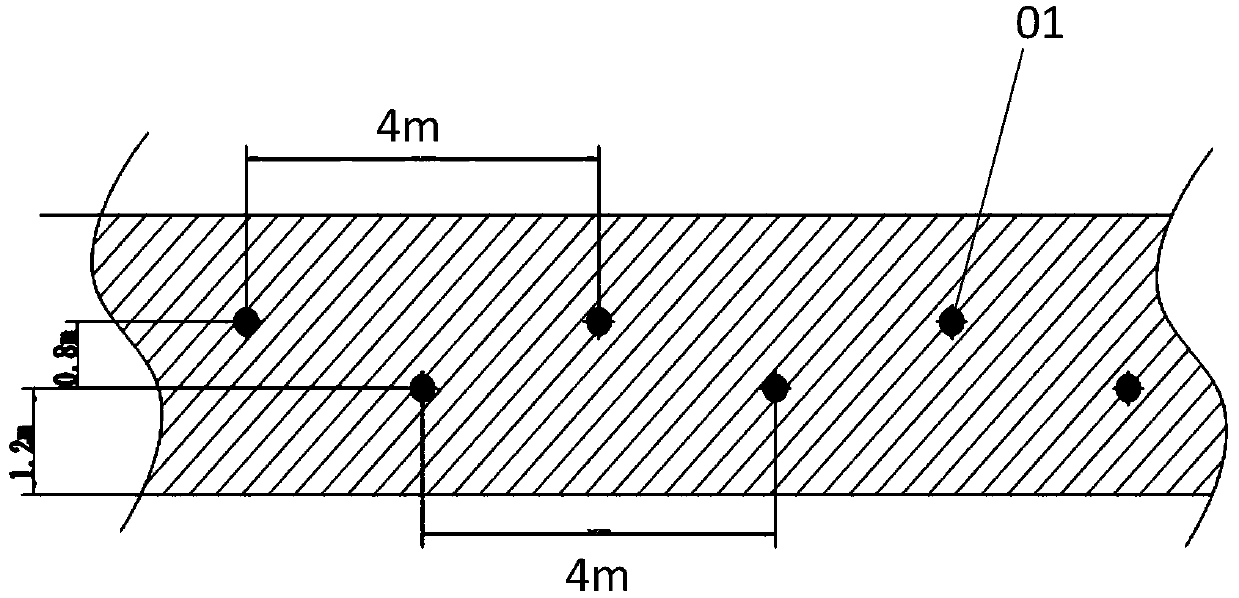

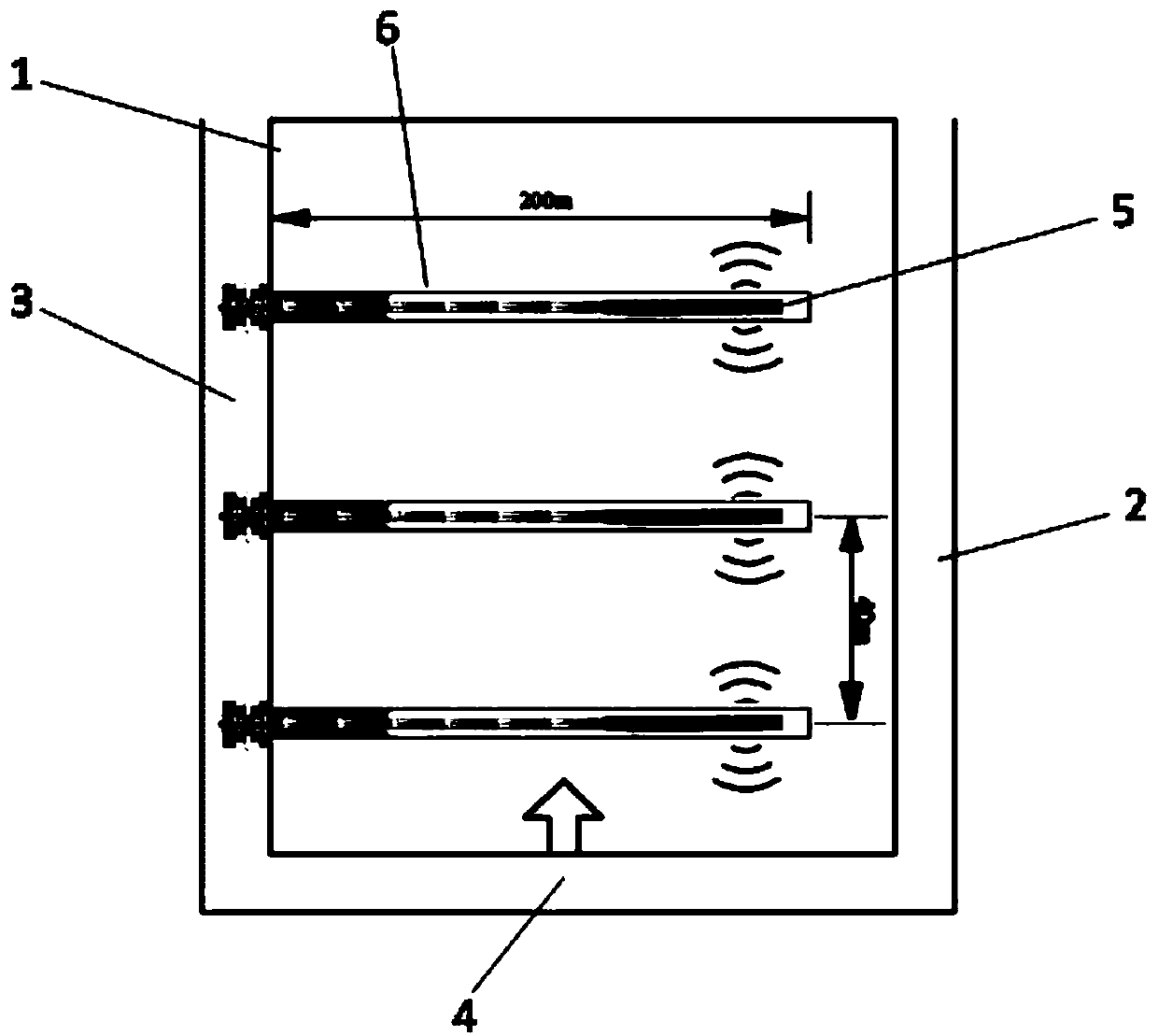

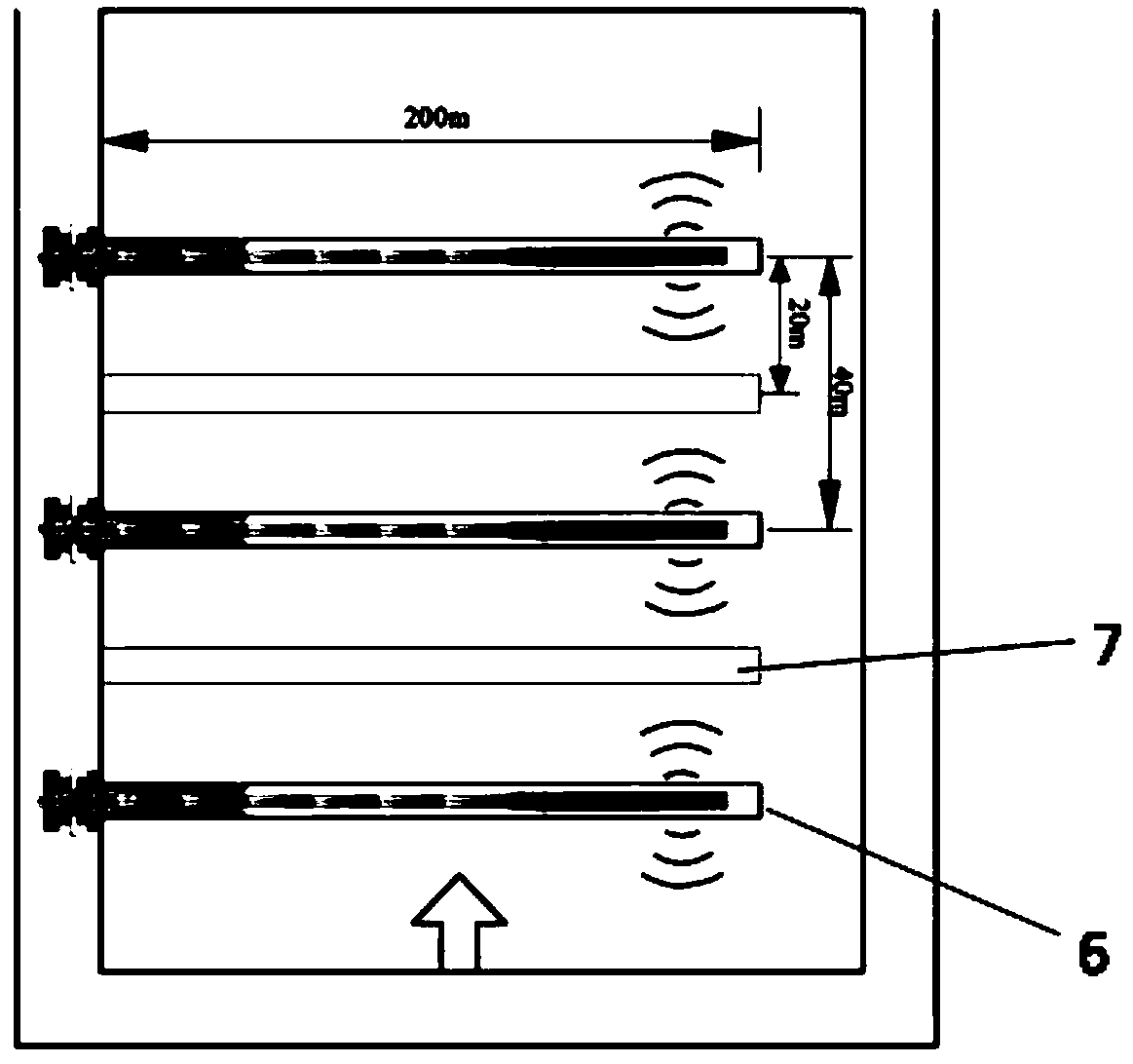

[0046] The present invention is based on the controllable shock wave technology for coal seam gas drainage, and the controllable shock wave generating device 5 is gradually exiting the anti-reflection borehole 6 under the control of the drilling rig. Points in turn conduct shock wave anti-reflection operations. The definition of controllable shock waves is that the amplitude and impulse are controllable, as well as the controllable area of action and the number of repeated actions. Through the control of the controllable shock wave intensity and area, the pores can be connected, expanded and extended without destroying the borehole, forming an interwoven three-dimensional network, thereby achieving the purpose of improving the efficiency of coal seam drainage. Compared with the gas drainage of the existing conventional scheme, this method has a significantly larger anti-r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com