Three-twisted-blade Roots type power machine power generation device

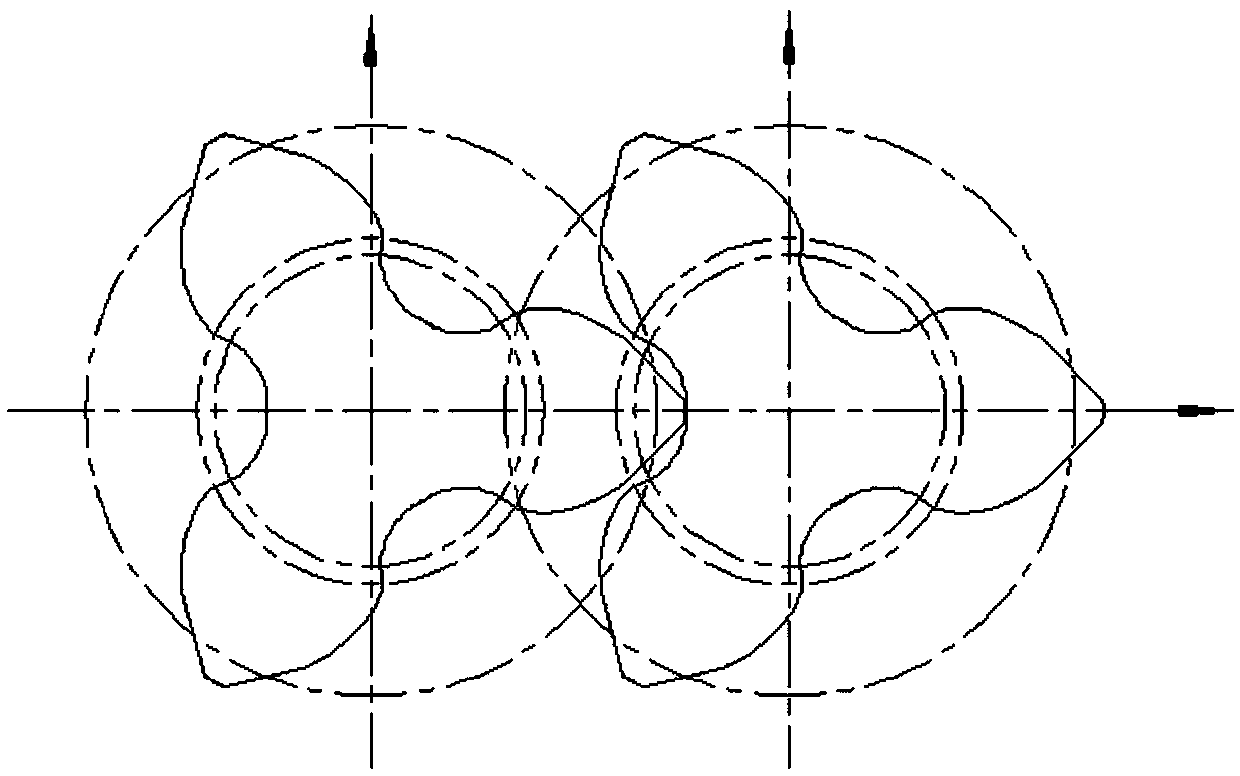

A technology for power generation devices and power machines, which is applied to rotary piston engines, intermeshing engines, engine components, etc., can solve problems such as low meshing coincidence of straight-blade rotors, large flow pulsation and impact noise, and poor rotor meshing smoothness. , to achieve the effect of improving the area utilization coefficient, reducing the airflow pulsation and running smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Specific examples of the present invention are given below. The specific embodiments are only used to describe the present invention in detail, and do not limit the protection scope of the present application.

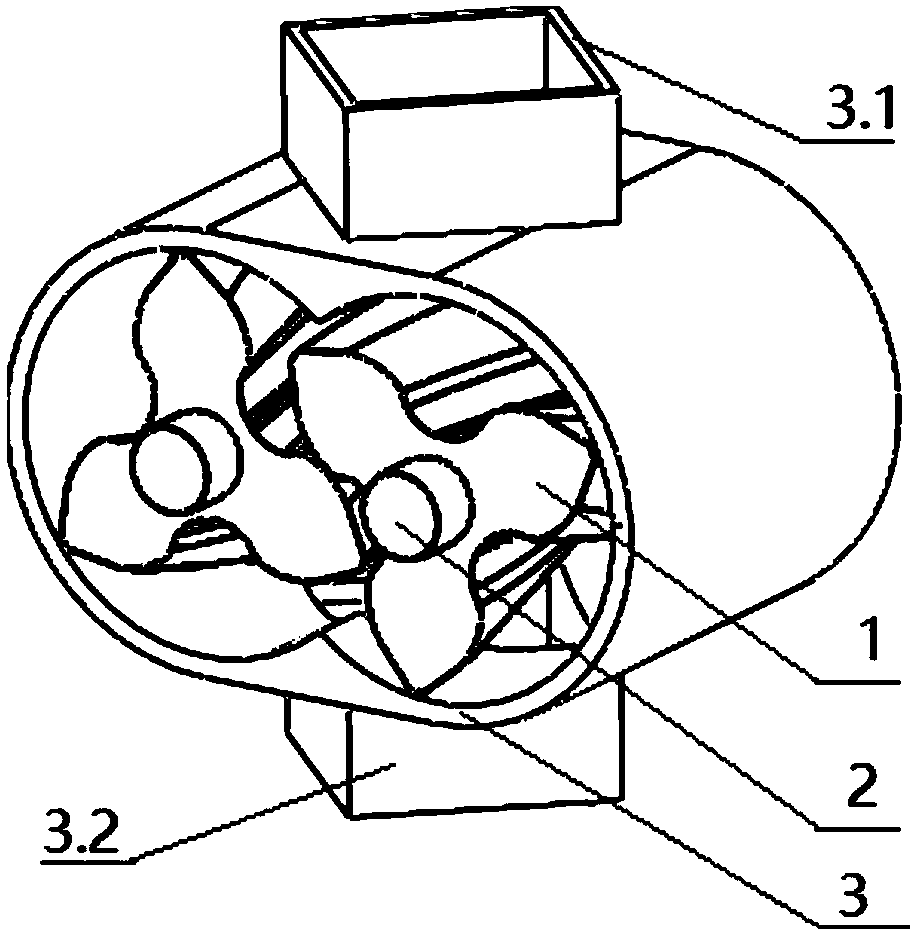

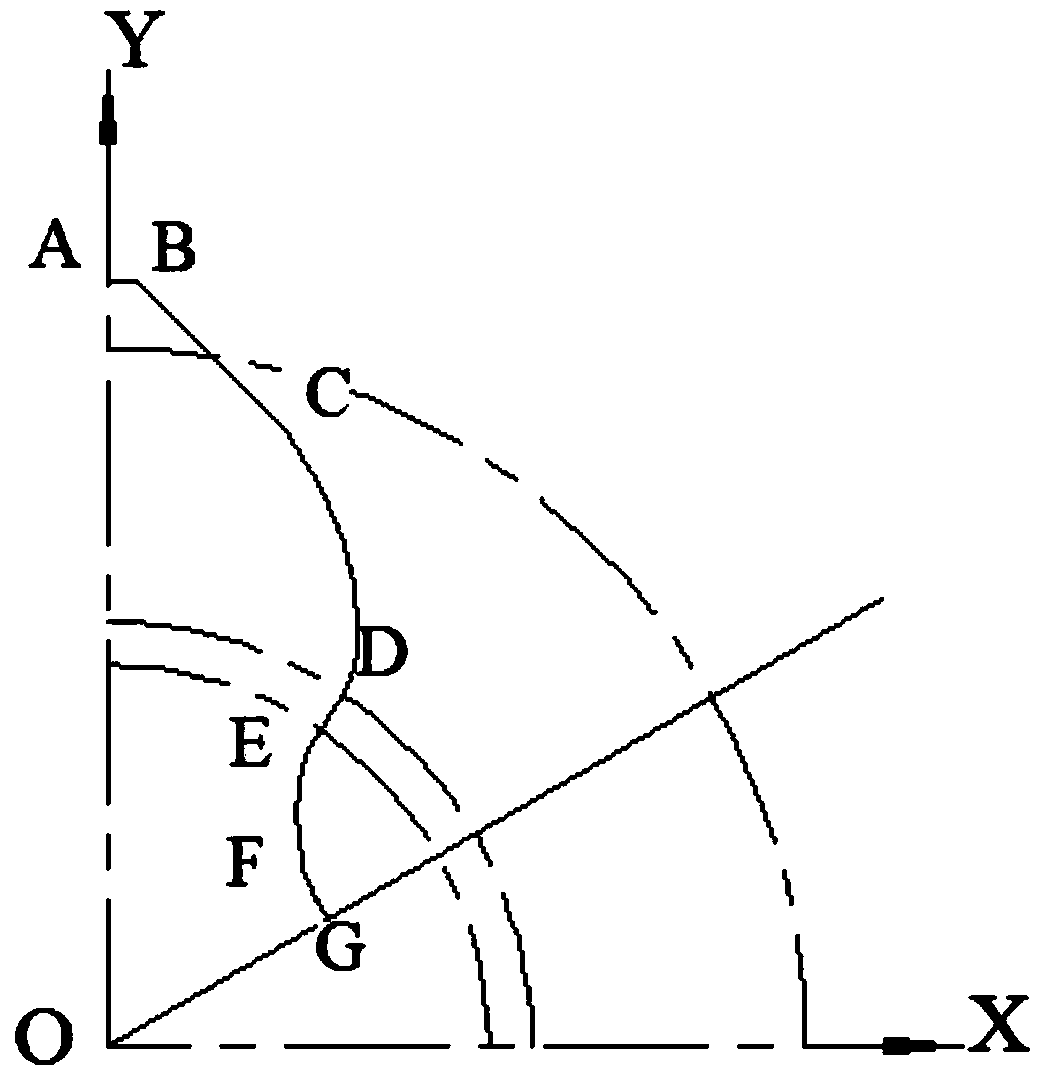

[0054] The Roots-type power generator power generation device of the present invention is a volumetric rotating machine, relying on low-quality waste heat to do work to push the meshing rotor to expand and do work, convert steam heat energy into mechanical energy, and the rotor drives the output shaft to rotate and do work to further convert the mechanical energy into electrical energy; its core components are The rotor 1 and the casing 3; the rotor adopts a pair of meshing three-lobed twisted-blade rotors 1, saturated steam enters the cavity, and the pressure difference pushes the rotor 1 to expand and do work; the casing structure 3 is relatively complicated, and the casing The shape of the air inlet 3.1 and the air outlet 3.2 has a particularly serious impact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com