Tight-contact temperature sensor allowing part insertion

A temperature sensor and pin technology, which is applied to thermometers, thermometer parts, thermometers using directly heat-sensitive electrical/magnetic components, etc., can solve the problems of temperature measurement deviation, slow response to temperature acquisition, and small contact area. , to achieve the effect of rapid temperature measurement, simple and reliable structure, and high temperature measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

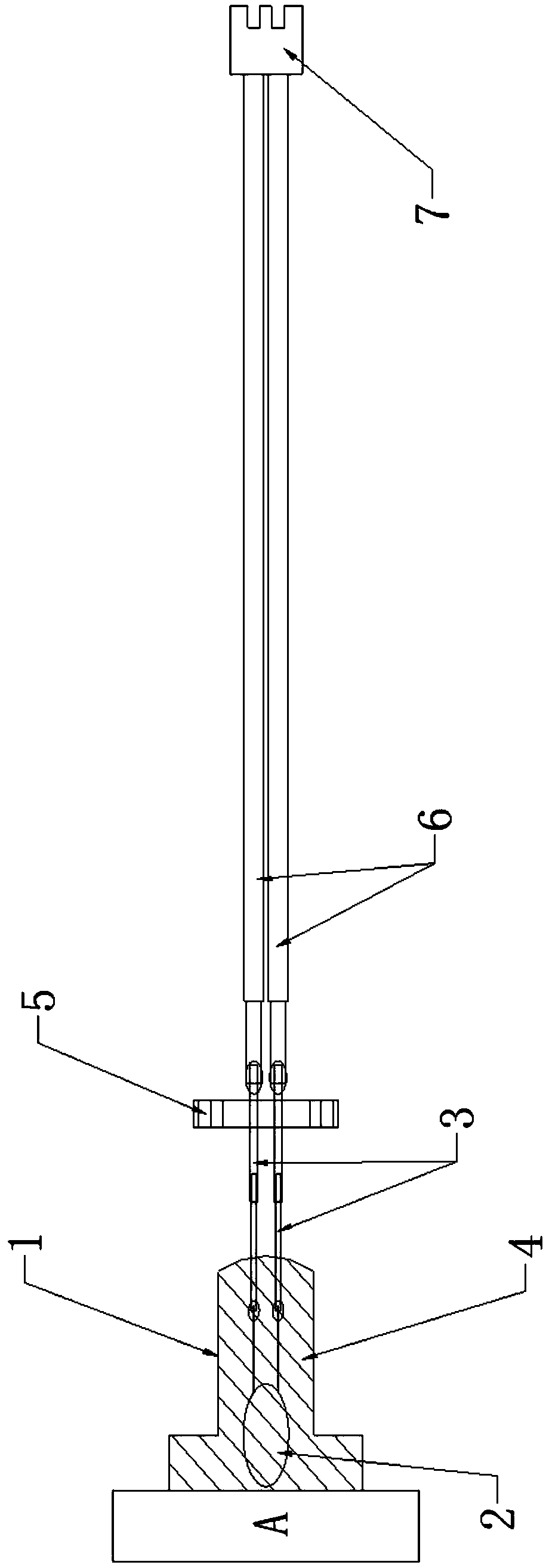

[0025] see figure 1 , the pluggable and close-fitting temperature sensor of the present invention includes a metal shell 1, a thermistor 2, two elastic and retractable pins 3, a packaging material 4, a fixing plate 5, two electronic wires 6, and a terminal 7 and connectors.

[0026] The thermistor 2 is arranged in the metal casing 1 . The two ends of the telescopic pin 3 are respectively a free end and a fixed end, and the two telescopic pins 3 are parallel to each other, and their free ends are respectively electrically connected to the two electrode leads of the thermistor 2, which The fixed end is arranged on the outside of the metal casing 1; the packaging material 4 is filled in the metal casing 1, and the thermistor 2 and the electrode leads of the thermistor 2 are connected to the retractable pin 3 The joint is packaged and fixed; the fixed plate 5 is fixedly connected to the fixed ends of the two retractable pins 3 .

[0027] Specifically, the metal casing 1 is a st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com