Die base on punching machine

A technology of mold library and punching machine, which is applied in the direction of piercing tools, forming tools, manufacturing tools, etc., can solve the problems of enlarged main machine width, high cost investment, and many pipeline layouts, and achieve the reduction of main machine width, debugging and maintenance Convenient and guarantee the effect of nominal pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

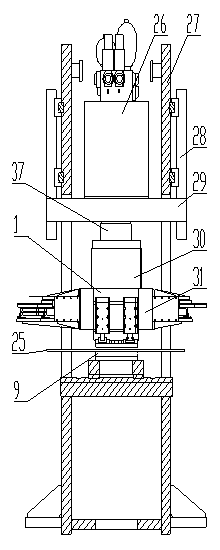

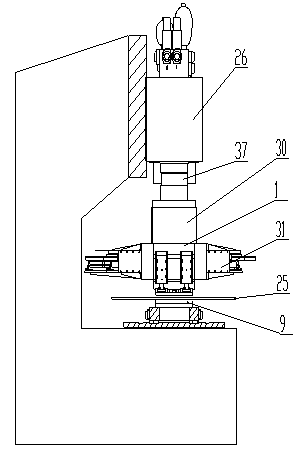

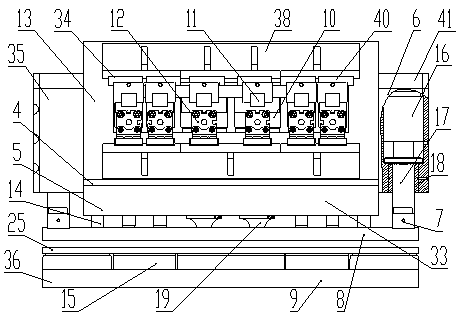

[0015] figure 1 and 2 It is an example of the application of array combined mold library, hydraulic main oil cylinder and main engine bed. figure 1 For assembling the main engine of the hydraulic master cylinder 26 through the main cylinder flange connection plate 29 and the closed bed by the main engine bed connecting plate 28. figure 2 For assembling by the main frame around the facade of the hydraulic main oil cylinder 26 and the open bed.

[0016] figure 1 The upper guide seat 1 of the middle array combined mold library assembly 31 is installed through the mold library connecting slider 30 and the hydraulic main cylinder piston rod 37 of the hydraulic main cylinder 26 installed on the main cylinder flange connection plate 29, which is an array combined type. The mold library component 31 provides the stamping power source; the flange connecting plate 29 of the main oil cylinder is connected with the main machine bed connecting plate 28 installed on the main machine bed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com