Monitoring system and method for loading of helicopter rotor and based on buried type optical fiber sensors

A helicopter rotor and fiber optic sensor technology is applied in the testing of aircraft components, the measurement of force by measuring the change of optical properties of materials when they are stressed, instruments and other directions, which can solve the problem of not meeting the requirements of real-time monitoring of composite structures Cost and economic costs, inability to achieve continuous load measurement, etc., to achieve the effect of strong practicability and reliability, reducing operation difficulty and enhancing protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

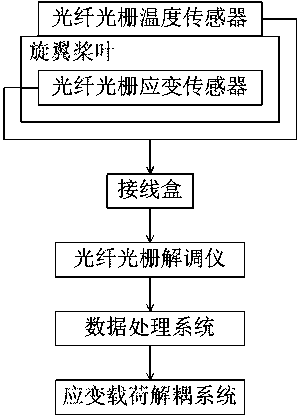

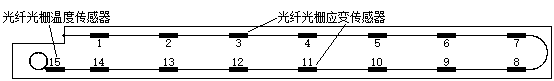

[0042] see figure 1 , the invention provides the helicopter rotor load monitoring system based on the embedded optical fiber sensor, comprising fiber grating sensor and control assembly; For the stress distribution of the rotor, the fiber grating strain sensor is embedded in the blade of the helicopter rotor near the edge; the control components include the fiber grating demodulator, data processing system and strain load decoupling system; the fiber grating demodulator passes through the light receiving end It is connected with the pigtail of the fiber grating sensor to demodulate the optical signal output by the fiber grating sensor; the data processing system is connected to the signal output port of the fiber grating demodulator through the signal input port to store and manage the fiber grating demodulator The output signal; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com