Soil layer interfacial shear testing machine and soil layer interfacial shear testing box

A technology of shear test and test chamber, applied in the direction of testing the strength of materials, measuring devices, instruments, etc. by applying a stable shear force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

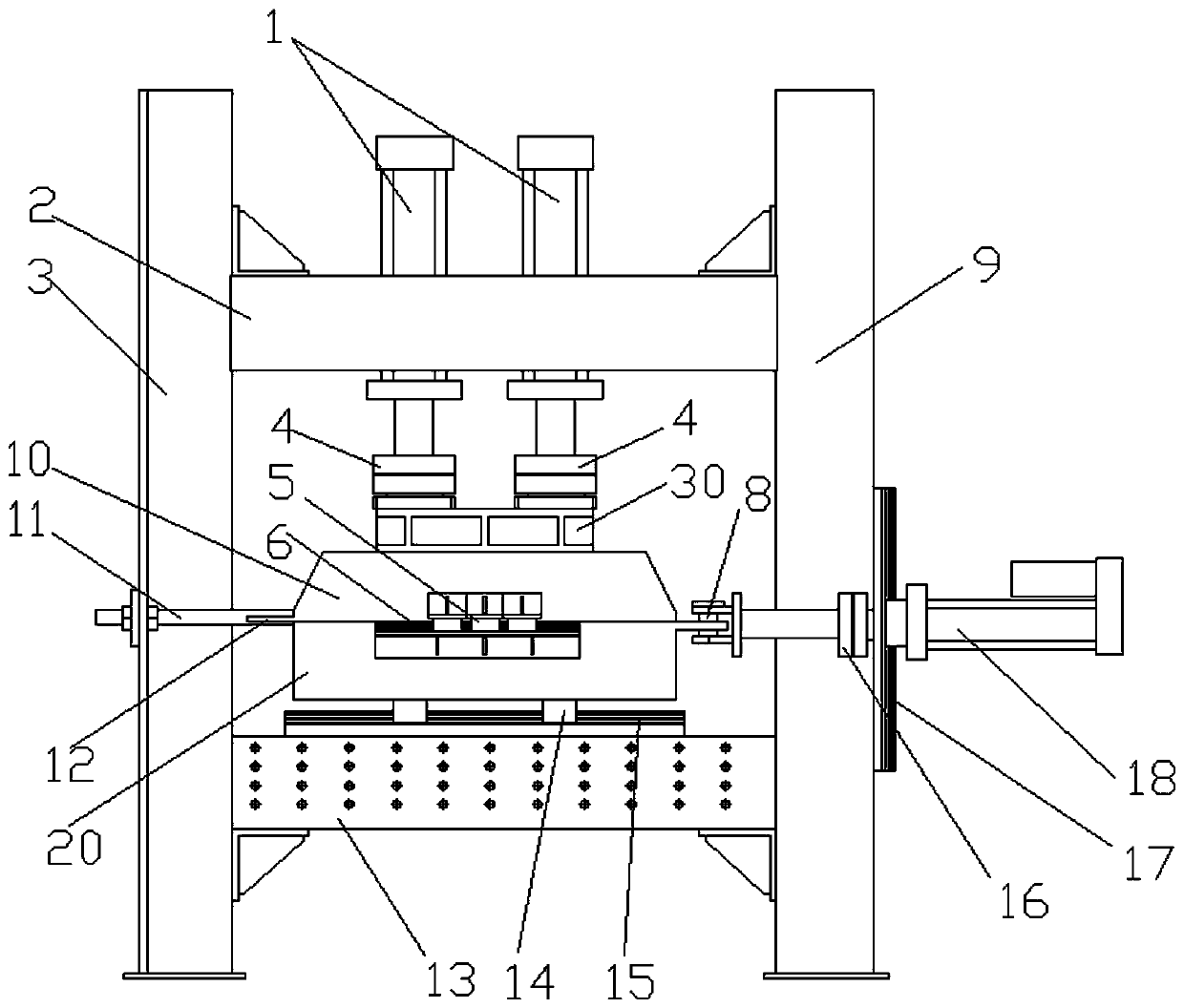

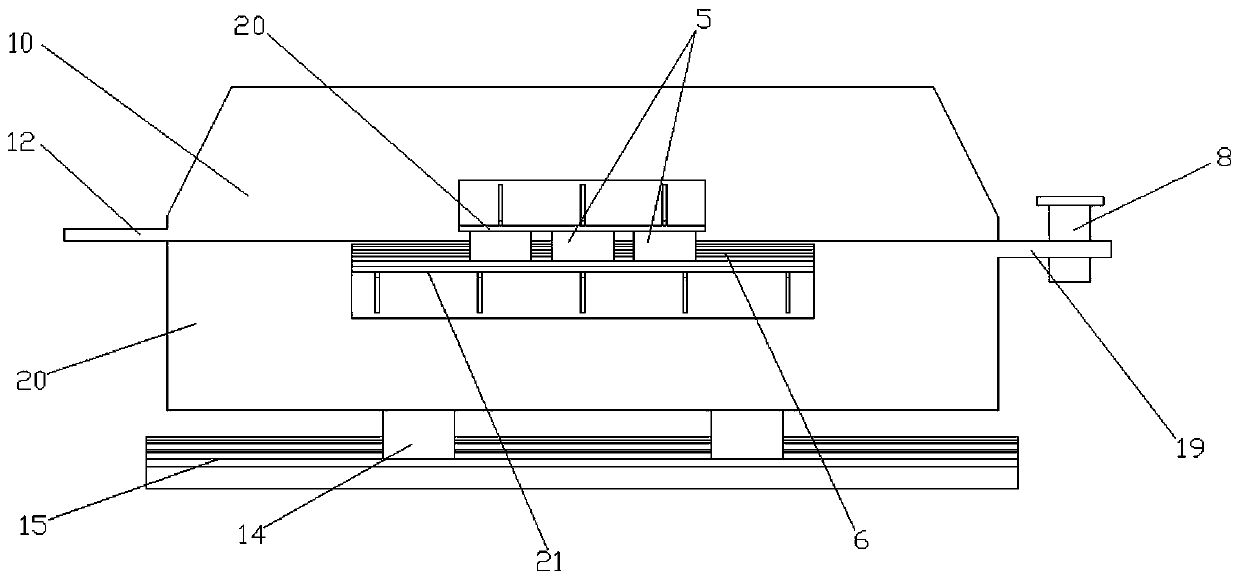

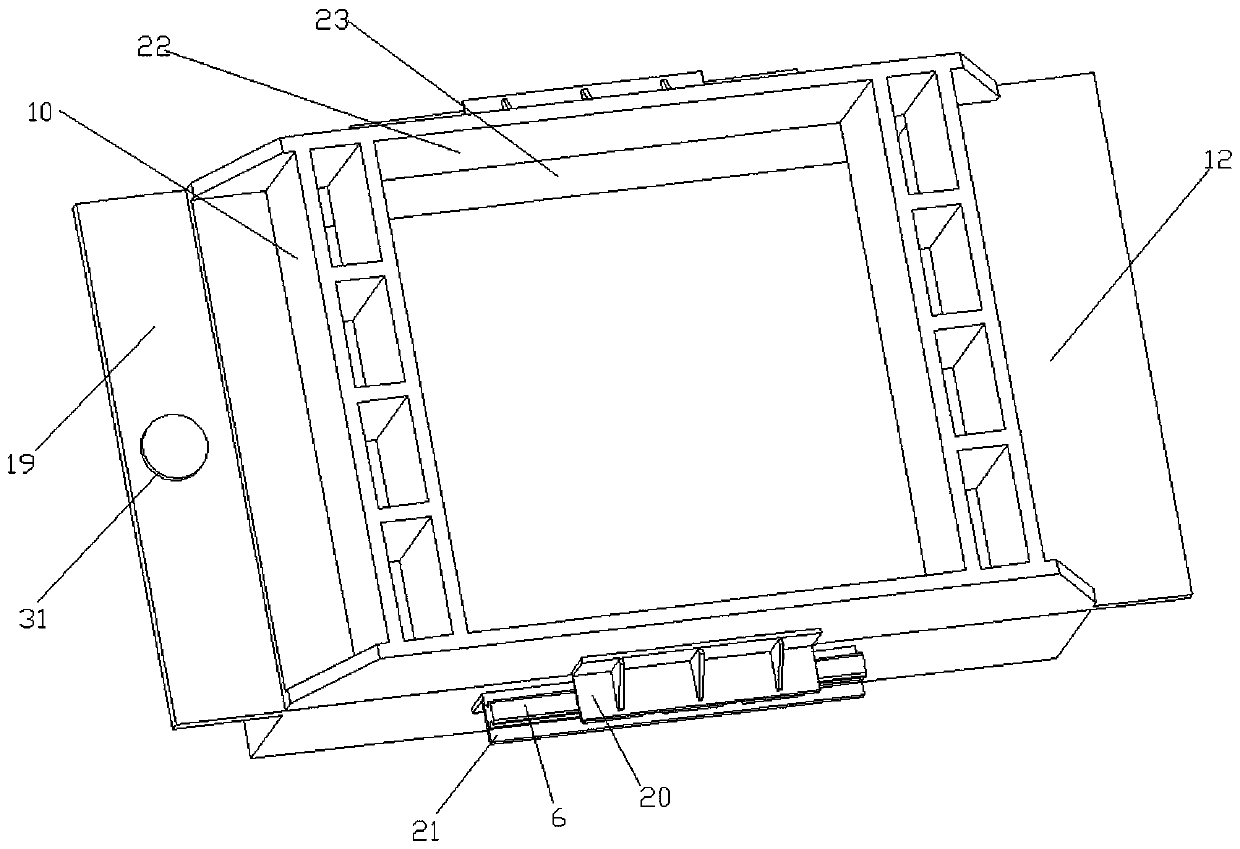

[0021] A kind of embodiment 1 of soil interface shear testing machine is as Figure 1~3 Shown: It includes a soil layer interface shear test box and a loading device. The loading device includes a device frame. The device frame includes two sets of columns arranged at intervals on the left and right. . A vertical loading mechanism is arranged on the top beam, and the vertical loading mechanism includes two vertical loading cylinders 1 arranged at intervals on the left and right. The piston rods of the two vertical loading cylinders 1 are connected with an upper pressure plate 30, and the piston rods of the vertical loading cylinders A first force sensor 4 is arranged between the rod and the upper pressing plate. The column 9 on the right side is provided with a vertical guide rail 17 extending vertically along the guide direction, and a lateral loading mechanism is equipped with a guiding movement on the vertical guide rail 17. The setting can be moved up and down to adjust ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com