Rock argillization process simulation process under movable water circulation and loading condition, and test method

A technology of process simulation and simulation device, which is applied in the direction of soil material testing, material inspection products, etc., can solve the problems of not being able to truly simulate the environmental conditions of engineering rock mass, so as to save experiment time, facilitate observation and recording, and ensure a stable flow rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

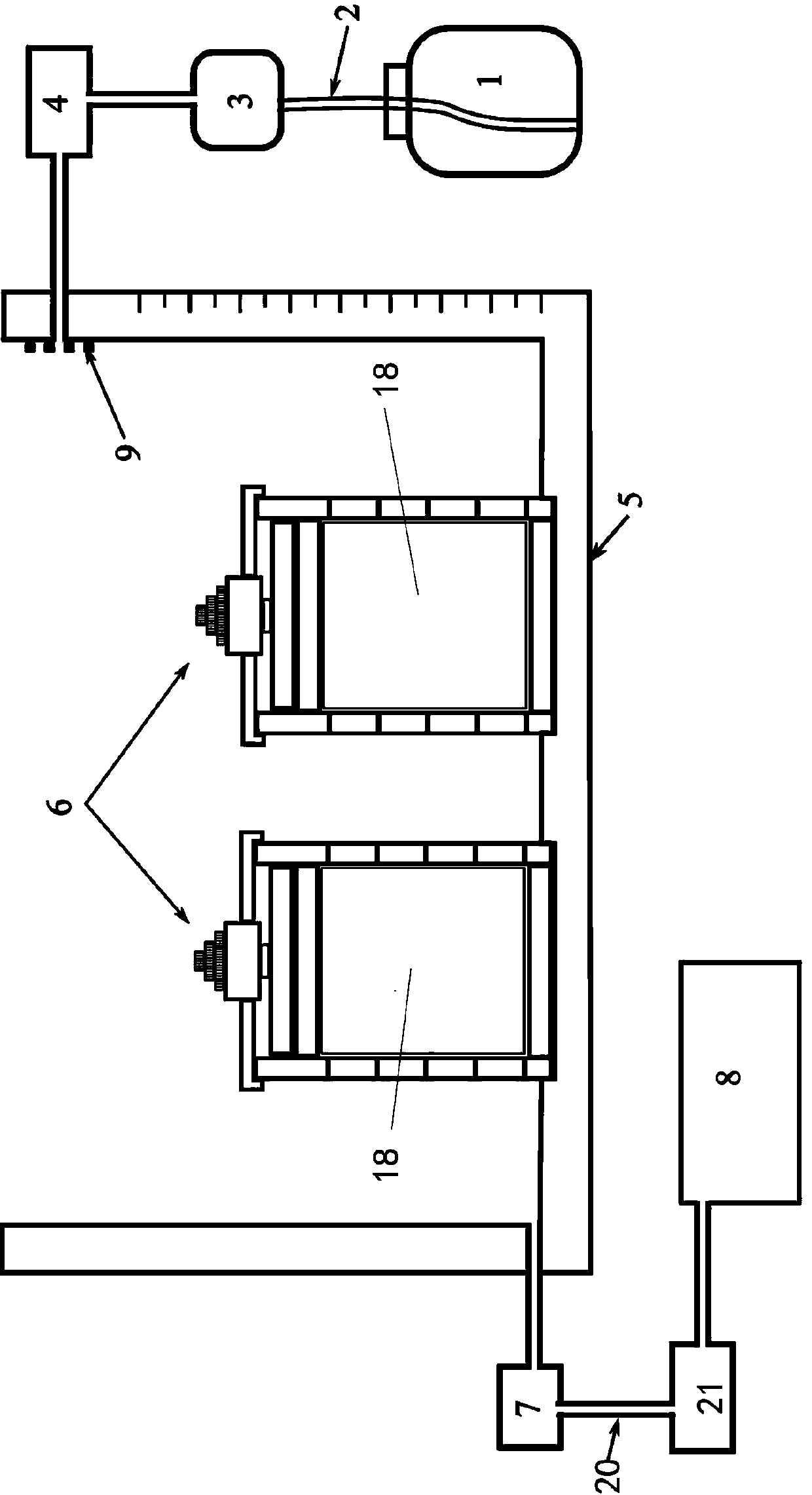

[0036] Such as figure 1 with figure 2 as shown,

[0037] A rock mudification process simulation device under dynamic water circulation and load conditions, including a water flow control device, the water flow control device communicates with the circulation device through the mudification simulation device;

[0038] The mudification simulation device comprises an outer bin body 5 with an opening at the top, at least one inner bin body 6 is installed at the bottom of the outer bin body 5, and a scale is arranged on the outer wall of the outer bin body 5, which is convenient for reading the water level in the bin;

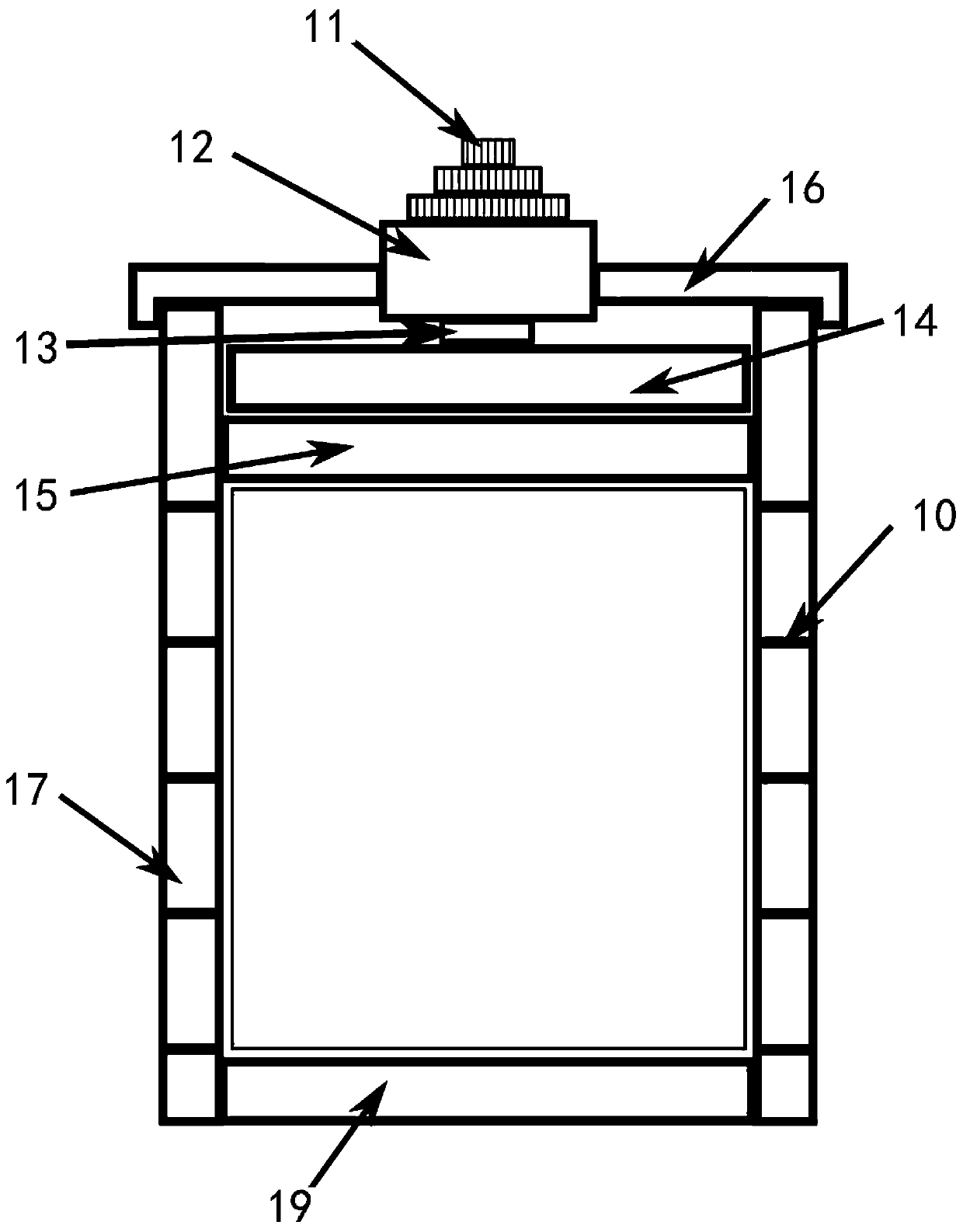

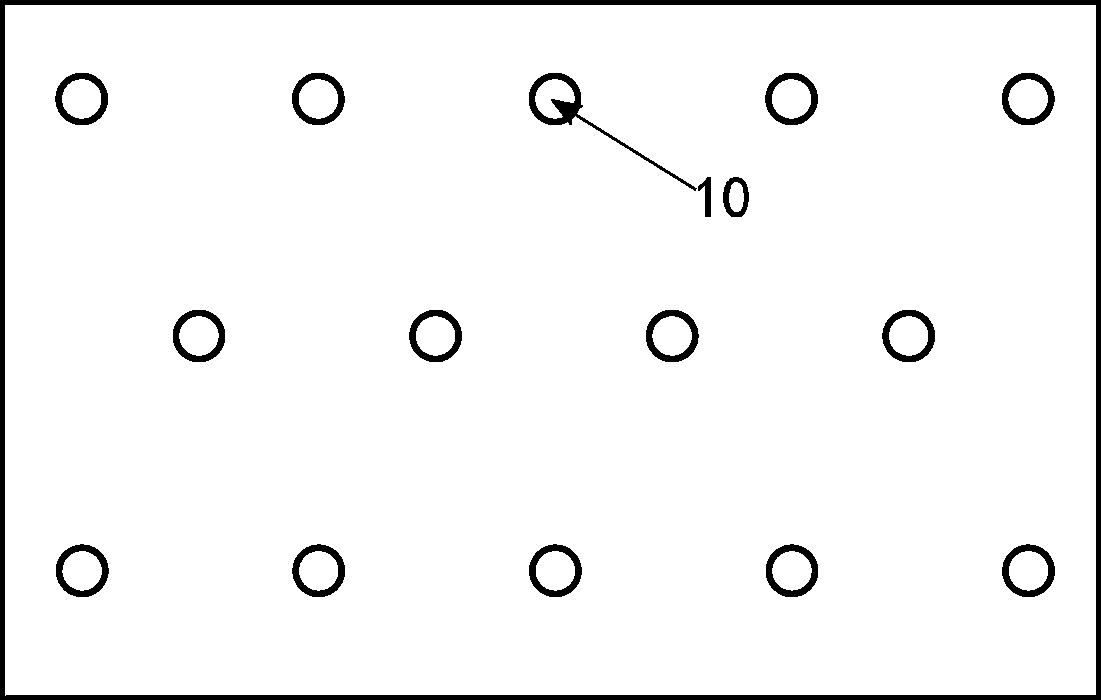

[0039] The inner chamber body 6 includes a container body 17 with an open top and a bottom end, and an upper permeable stone 15 and a lower permeable stone 19 matched with a rock sample 18 are arranged in the container body 17, and a fixed baffle plate 16 with a loading device and an upper permeable stone 19 are provided. The water-permeable stone 15 is matched, ...

Embodiment 2

[0049] A kind of method adopting above-mentioned device to carry out rock mudification test, this method comprises the following steps:

[0050] Step 1: Loading samples: put the inner bin body 6 required for the test into the outer bin body 5, install the lower permeable stone 19 at the bottom of the inner bin body 6, and then put the rock sample 18 into the container of the inner bin body 6 In the body 17, a permeable stone 15 is installed on the top of the rock sample 18;

[0051] Step 2: Loading: Install a fixed baffle plate 16 with a loading device on the upper part of the upper permeable stone 15, so that the pressure bearing plate 14 is installed on the upper permeable stone 15, the number of weights 11 loaded, the loading rate, and the load action time of each level Apply according to the test requirements;

[0052] The determination method of the load p applied on the rock sample 18 is as follows:

[0053]

[0054] Wherein, p is the load acting on the rock sample 18...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com