Roasting device

A baking device and baking cavity technology, which is applied in the direction of instruments, nonlinear optics, optics, etc., can solve problems such as abnormal shutdown, overbaking of substrates, and affecting the normal progress of upper and lower processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

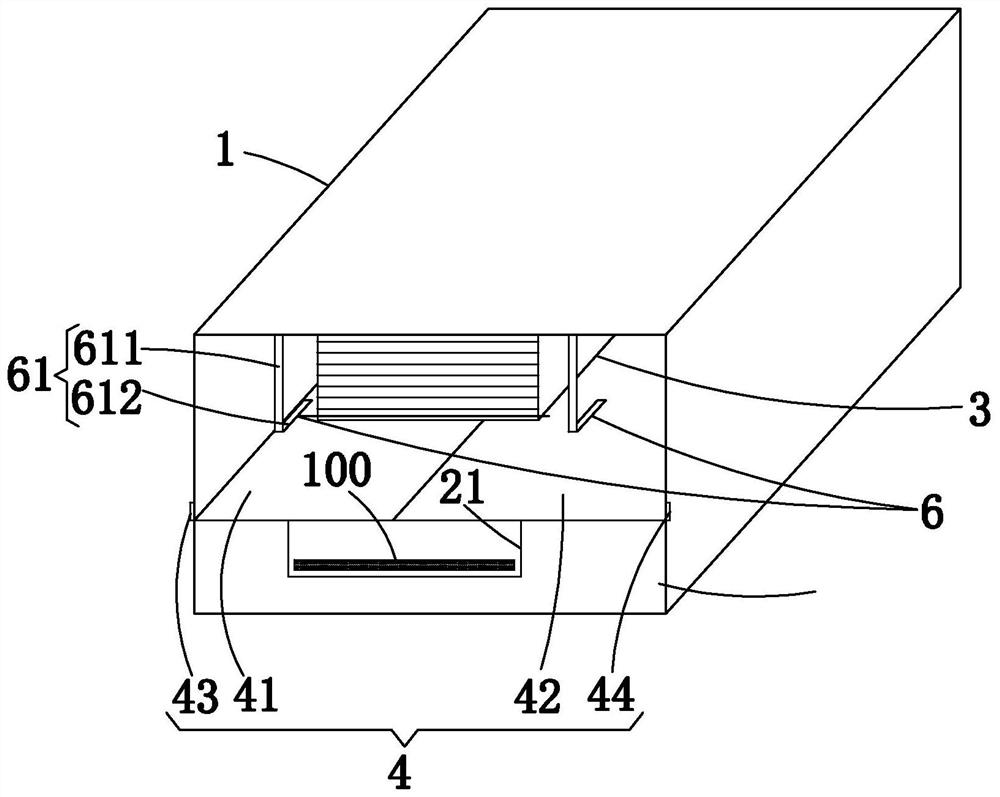

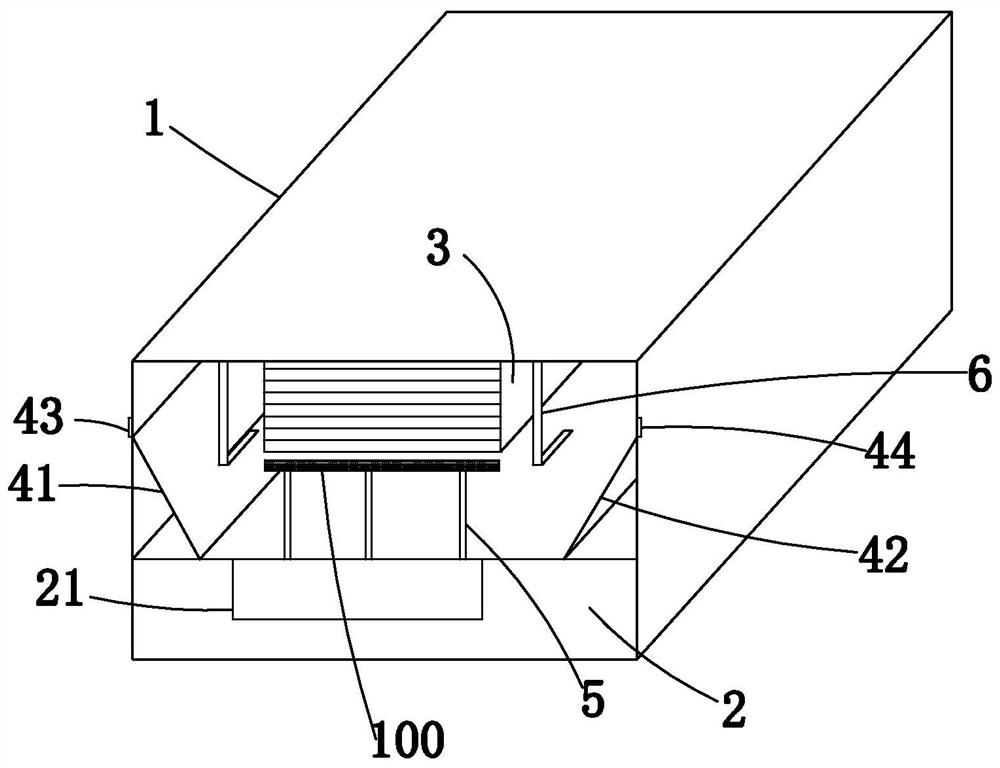

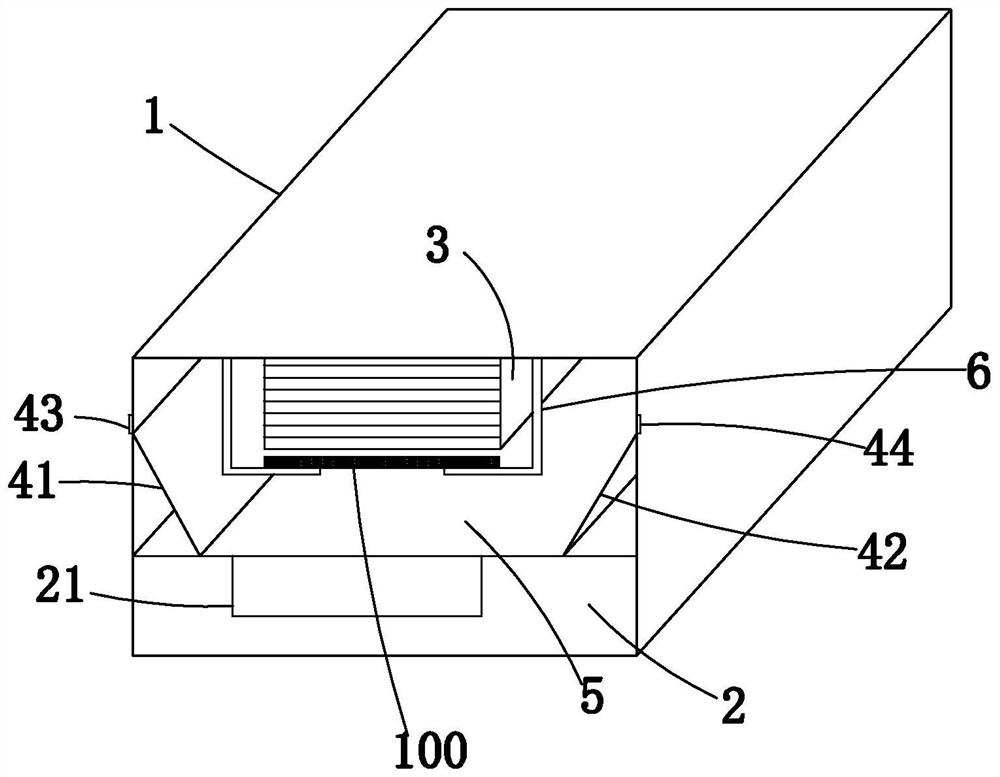

[0032] see figure 1 , the present invention provides a baking device, comprising a box body 1, a baking chamber 2 arranged in the box body 1 and located at the bottom of the box body 1, arranged in the box body 1 and located at the The cooling chamber 3 on the top of the box body 1, the heat insulation chamber door 4 on the top of the baking chamber 2, a plurality of evenly distributed supporting thimbles 5 arranged in the baking chamber 2, and the The carrying mechanism 6 in the box body 1 and between the baking chamber 2 and the cooling chamber 3, the baking chamber 2, the carrying mechanism 6 and the cooling chamber 3 are spaced from each other;

[0033] During baking, when the substrate 100 is baked in the baking chamber 2 and reaches the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com