Setting machine tail gas flue gas particulate matter concentration detection system and method

A particle concentration and detection system technology, which is applied in the field of particle concentration detection system in the tail gas of the setting machine, can solve the problems of zirconia loss, failure to respond to the degree of fabric drying in time, and increase the cost of real-time online detection, etc., to achieve Good real-time performance and avoid over-baking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

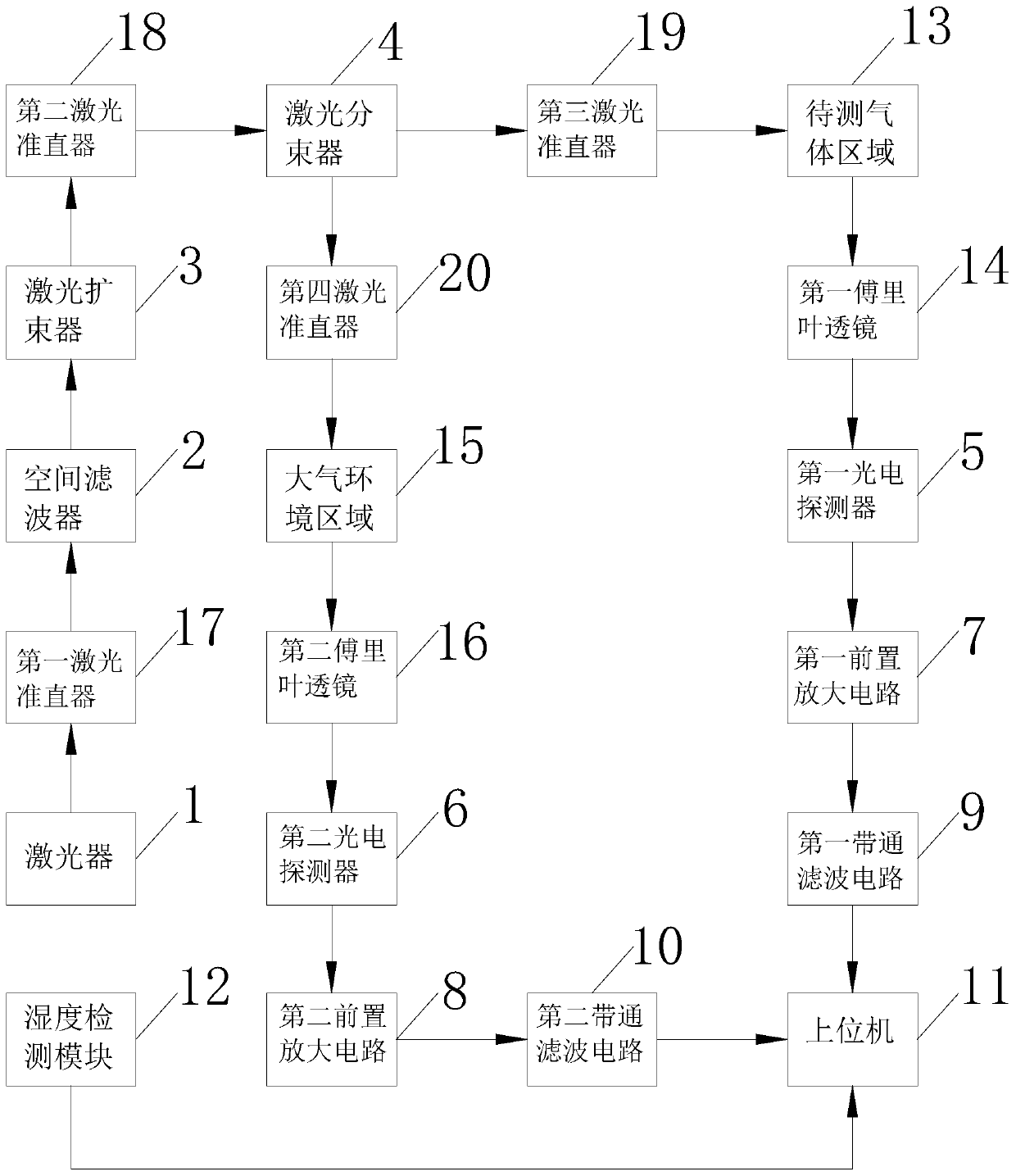

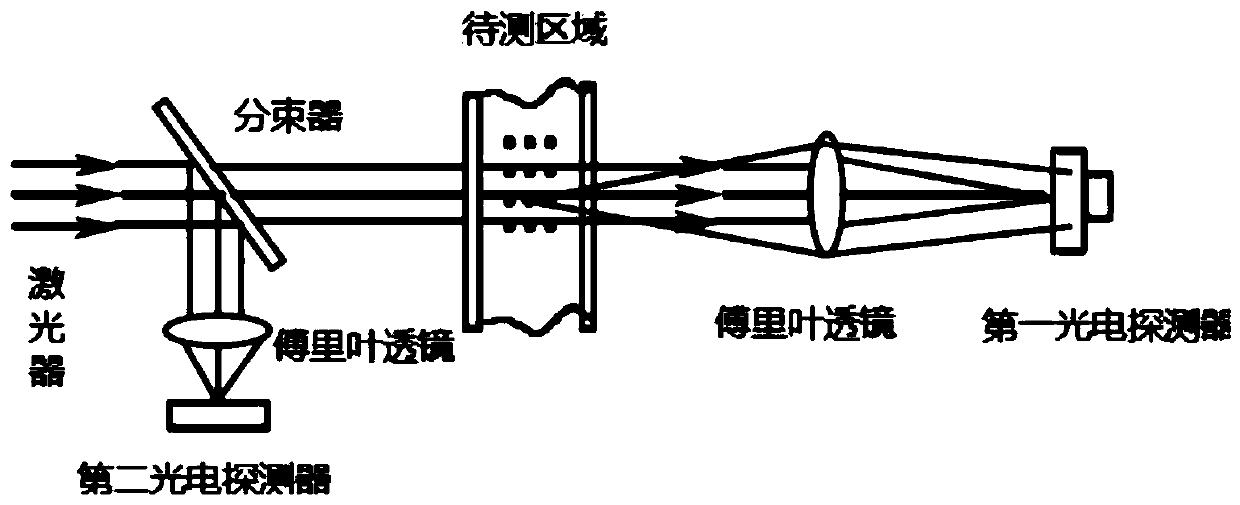

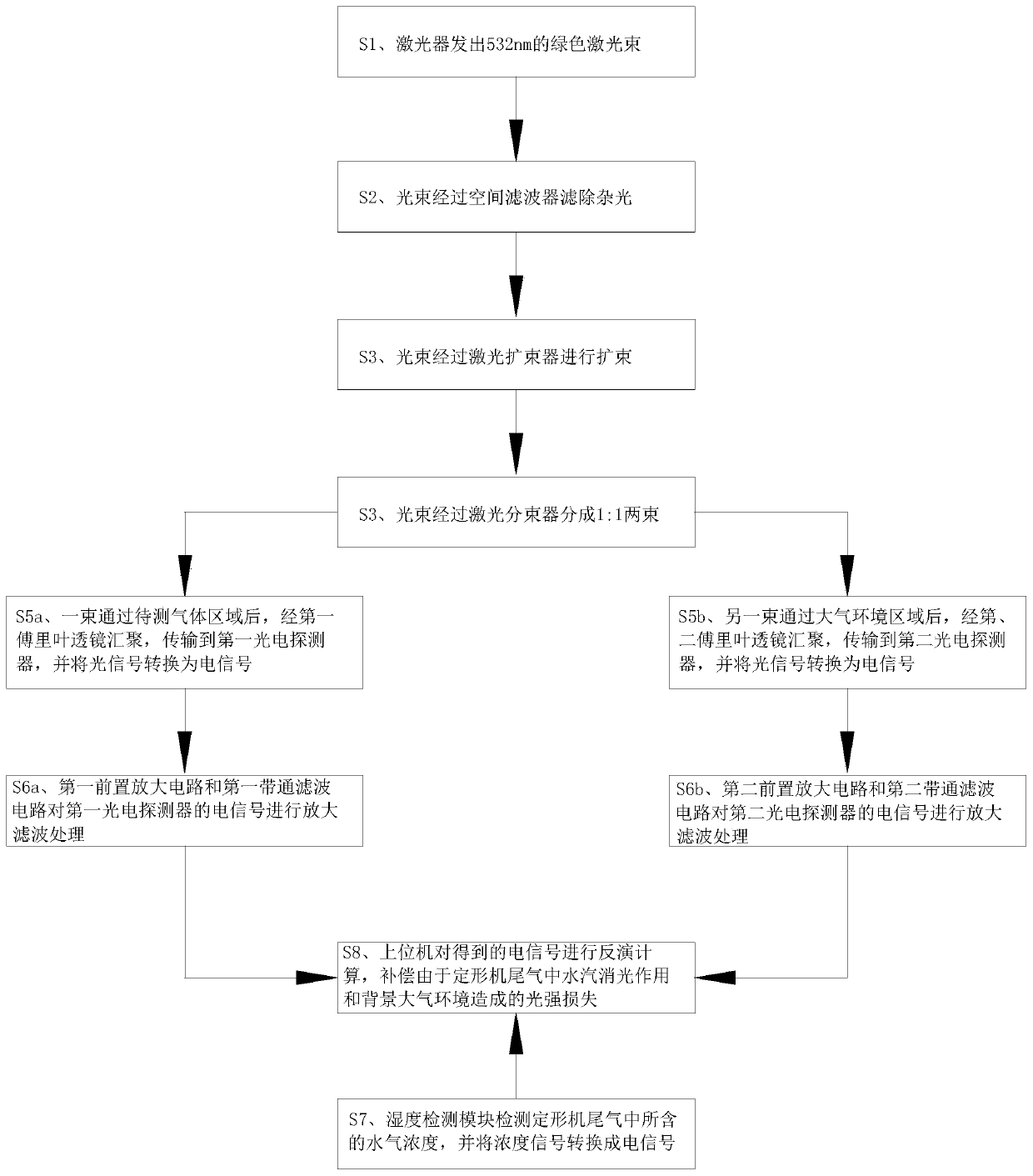

[0031] A detection system for the concentration of smoke particles in the tail gas of a setting machine, please refer to the attached figure 1 - attached figure 2 The detection system includes a laser 1, a spatial filter 2, a laser beam expander 3, a laser beam splitter 4, a first photodetector 5, a second photodetector 6, a first preamplifier circuit 7, a second Preamplifier circuit 8, first band-pass filter circuit 9, second band-pass filter circuit 10, host computer 11, and humidity detection module 12; laser light emitted by laser 1 is filtered by spatial filter 2 and then injected into laser expansion The beam splitter 3 is injected into the laser beam splitter 3, and the laser beam splitter 3 splits the injected laser beam into the first laser beam and the second laser beam at 1:1; the first laser beam passes through the gas to be measured vertically After the area 13 is injected into the first photodetector 5 through the first Fourier lens 14, the first photodetector ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com